Freeman Technology is pleased to announce the release of ‘Understanding the Impact of High-Shear Blending’.

In many industries, powders are combined with other powders, or binders, in high-shear blending operations, forming homogeneous mixtures for further downstream processing. The diverse range of blender sizes, geometries and methodologies means that performance can vary from machine to machine, producing mixtures with different flow properties that perform differently in subsequent operations.

It is important to understand the influence of any given unit operation on downstream performance, as incompatibility can lead to a product that is out of specification and not fit for purpose. This requires an understanding of how the powder and the process interact with each other and, once understood, the process can be optimised to deliver a product with desirable properties. This provides significant commercial benefits in terms of higher productivity and reduced wastage.

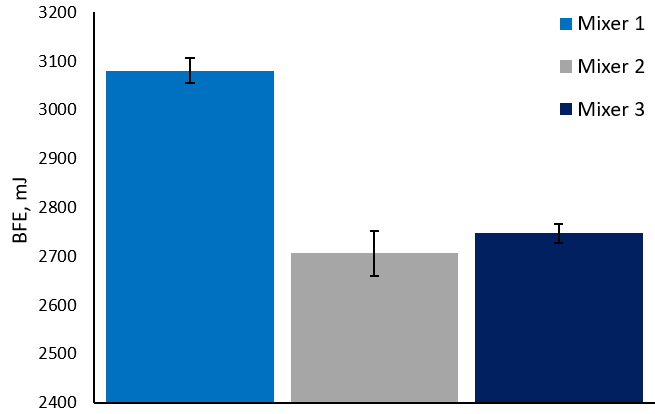

Three Magnesium Oxide based blends, produced using different equipment, were evaluated using the FT4 Powder Rheometer® to assess the influence of the production method, and the impact on product quality.

Please click here to view or download the application note.