Jan 24 2018

According to a team of Penn State researchers, integrating two different polymer forms can switch manufacturing of silicone parts from molding, casting and spin coating basic forms, to 3D printing intricate geometries, with improved mechanical characteristics and better biological adhesion.

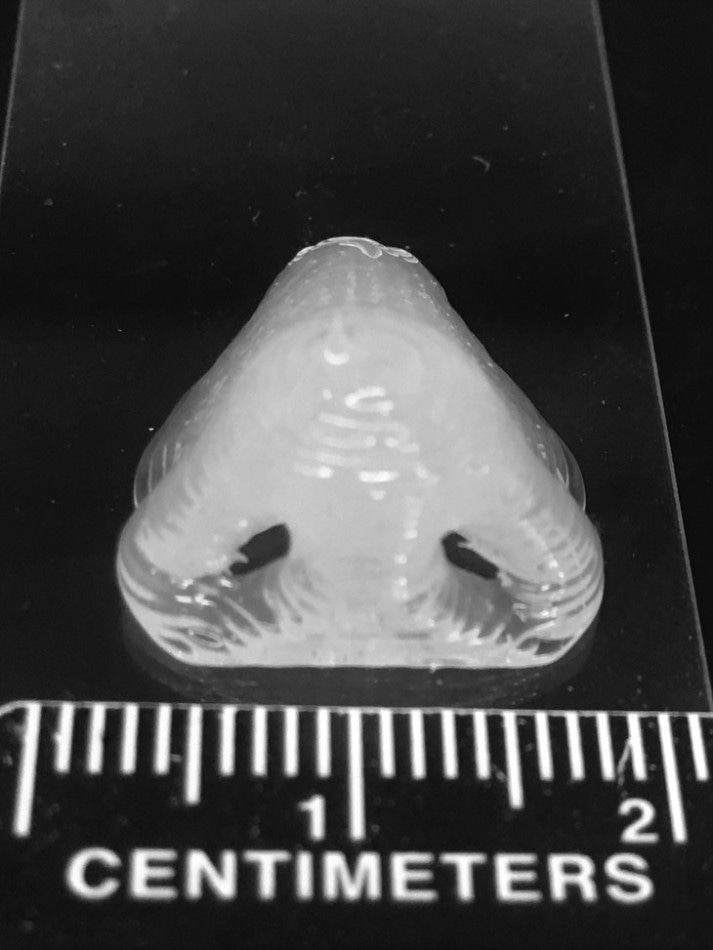

A nose created using 3D printing of PDMS from National Institutes of Health 3D Print Exchange. (Image credit: Ibrahim Tarik Ozbolat Lab / Penn State)

A nose created using 3D printing of PDMS from National Institutes of Health 3D Print Exchange. (Image credit: Ibrahim Tarik Ozbolat Lab / Penn State)

"So far, PDMS (polydimethylsiloxane, or silicone) has limitations in formability and manufacturing of devices," said Ibrahim T. Ozbolat, Hartz Family Associate Professor of Engineering Science and Mechanics and Bioengineering. "Most research is done using casting or micro molding, but this fabrication yields materials with weak mechanical properties and also weak cell adhesion. Researchers often use extracellular proteins like fibronectin to make cells adhere."

PDMS is used to produce lab-on-a-chip devices, two- and three-dimensional cell culture platforms, organ-on-a-chip devices and biological machines. The material is more commonly used in flexible baking pans and heat-resistant silicone spatulas, but these are geometrically simple and can be effortlessly molded. If the material is used for growing tissue cultures or testing, the geometries become much smaller and more multifaceted.

For any material to serve as "ink" in a 3D printer, it must be able to pass through the printing nozzle and maintain shape once it is deposited. The material cannot seep, spread or flatten, otherwise the integrity of the design vanishes. Sylgard 184, an elastomer of PDMS, is not adequately viscose to use in 3D printing - the material just flows out of the nozzle and puddles. However, when it is blended with SE 1700, another PDMS elastomer, in the proper ratio, the mixture is printable.

"We optimized the mixture for printability, to control extrusion and fidelity to the original pattern being printed," said Ozbolat.

The researchers improve the mixture to exploit a materials property known as "shear thinning." They report their results in the January edition of ACS Biomaterials Science & Engineering.

While a majority of materials become more viscose under pressure, certain materials have the opposite, non-Newtonian reaction. This is ideal for 3D printing because a fluid that is viscose enough to stay in the nozzle then becomes less viscose when the pressure of pushing out the "ink" takes place. Once the material leaves the nozzle, it regains its viscosity and the fine threads deposited on the object retain their shape.

When molded, PDMS has a smooth surface and is also hydrophobic. Combine those two properties together and the molded surface of PDMS is not an easy place for tissue cells to stick. Researchers often use coatings to boost cell adherence. 3D-printed surfaces, because they are composed of numerous miniature strands of PDMS, have minute crevices that provide cells a place to stick.

To test the reliability of 3D printing with PDMS, the team got patterns for biological features — noses, hands, ears, blood vessels and femoral heads, from the National Institutes of Health 3D Print Exchange. With the aid of these patterns, they 3D printed a nose. Organs like this can be printed without support materials and include hollow cavities and intricate geometries.

We coated the PDMS nose with water and imaged it in an MRI machine. We compared the 3-D reconstructed nose image to the original pattern and found that we had pretty decent shape fidelity.

Ibrahim T. Ozbolat

Since PDMS is forced via a nozzle for printing, the number of bubbles in the end material is far less than with casting or molding. Passing through a micrometer size needle eradicates most of the bubbles.

When we compared the mechanical signatures of molded or cast PDMS with 3D printed PDMS, we found the tensile strength in the printed material was much better.

Ibrahim T. Ozbolat

Since the PDMS materials are being printed, they could be added with other materials to create one-piece devices made up of multiple materials. They could also integrate conductive materials to enable functional devices.

Other researchers on this project were Veli Ozbolat, postdoctoral fellow in engineering science and mechanics; Madhuri Dey, doctoral students in chemistry; Bugra Ayan, doctoral student in engineering science and mechanics; Adomas Povilianskas, bachelor's/master's student in engineering science and mechanics; and Melik C. Demirel, professor of engineering science and mechanics.

This work was supported by the Scientific and Technological Research Council of Turkey and the Turkish Ministry of National Education.