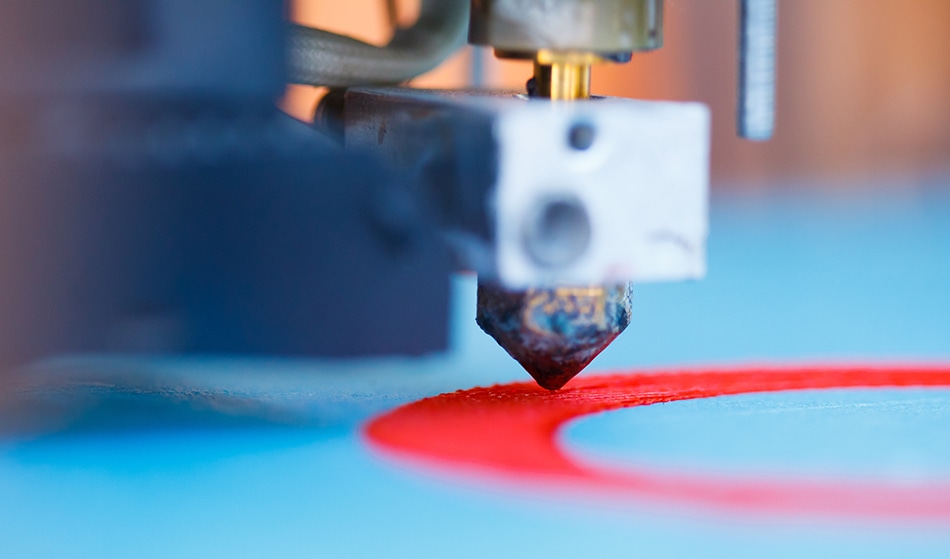

Scientists have taken a major step forward toward the rapid manufacture of flexible display technology and other stretchable electronic devices, which includes soft robotics, with the development of a 3D-printable ‘paste-y alloy' that can conduct electricity.

The development could enable the 3D printing of relatively tall, intricate and pliable structures capable of carrying electricity. To create the alloy, scientists placed nickel nanoparticles into the liquid metal galinstan, thickening it into a paste suitable for additive manufacturing, according to a report on the development, published in the journal Advanced Materials Technologies.

Image credit: nikkytok/shutterstock

Image credit: nikkytok/shutterstock

“With the paste-like texture, it can be layered while maintaining its capacity to flow, and to stretch inside of rubber tubes,” study author Yiğit Mengüç, assistant professor of mechanical engineering at Oregon State University, said in a news release. “We demonstrated the potential of our discovery by 3D printing a very stretchy two-layered circuit whose layers weave in and out of each other without touching.”

Gallium alloys happen to be quite popular as conductive materials in soft electronics; they have low toxicity, low cost, and excellent conductivity. Also, they’re capable of “self-healing”; attaching together again at break points.

However, before this development, which used sound energy to combine the nickel particles and oxidized gallium into the liquid metal, gallium alloys’ printability was limited to flat forms. Scientists behind the new study were able to print structures as high as 10 millimeters and as wide as 20 millimeters.

This advancement in liquid metal printing could have major implications for flexible electronics, the study team said, because it facilitates the rapid creation of intricate, bendable circuitry designs via 3D printing. This nascent area of electronics already includes a wide range of products, including conductive textiles, bendable displays, flexible sensors, wearable sensors, antennae and biomedical devices. There’s also the promise of ‘soft robots’ – robots that have the pliability of an octopus or jellyfish.

The future is very bright. It’s easy to imagine making soft robots that are ready for operation that will just walk out of the printer.

Doğan Yirmibeşoğlu, Co-Author and Robotics Ph.D. student - OSU

The new study means researchers can now make flexible electronic devices quickly and easily.

“The electrical properties of the paste are comparable to pure liquid metal, and the paste retains self-healing characteristics,” said study author Uranbileg Daalkhaijav, a Ph.D. candidate in chemical engineering at OSU.

The study team said their future work in this area would focus on investigating the precise structure of the new material, how the nickel particles are stabilized and how aging affects the paste.

The new development comes after a team of Stanford University researchers announced last month that they had developed flexible, touch-sensitive electronics, which could pave the way for the development of highly-responsive artificial skin.

In a report published by the journal Nature, the Stanford team described the development of flexible, polymer circuitry with built-in touch-sensors that could identify the delicate touch of an artificial ladybug. The report also described a technique to mass produce this flexible circuitry, a key step on the path to commercialization.

Study scientists said they hope prosthetics manufacturers might one day be capable of connecting their flexible, multipurpose circuits with a person’s nervous system. This artificial skin would be able to sense touch, temperature, and other phenomena. Artificial skin based on the research could also have countless other applications, including biomedical devices and robotics.

Although this kind of artificial skin is a long way from becoming a reality, the processes reported in the new study could enable the production of bendable, stretchable touchscreens, smart clothing or skin-like patches for medical uses.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.