Apr 26 2018

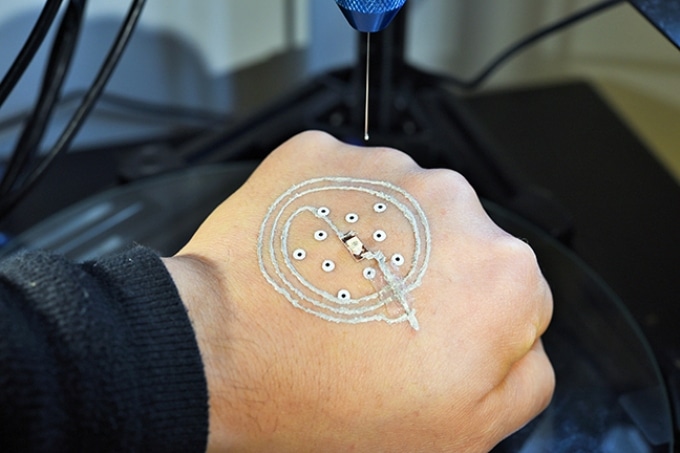

One of the key innovations of the new 3D-printing technique on skin is that the printer uses computer vision to track and adjust to movements in real-time. (Credit: McAlpine group, University of Minnesota)

One of the key innovations of the new 3D-printing technique on skin is that the printer uses computer vision to track and adjust to movements in real-time. (Credit: McAlpine group, University of Minnesota)

A customized, economical 3D printer was used by scientists at the University of Minnesota in an innovative new study to print electronics on a real hand for the first time. The technology could be employed by soldiers during a war to print temporary sensors on their bodies to detect biological or chemical agents or solar cells to charge vital electronics.

Biological cells were also successfully printed by the scientists on the skin wound of a mouse. The method could pave the way for new medical treatments for wound healing and direct printing of grafts for skin maladies.

The study was published on April 26 on the inner back cover of the academic journal Advanced Materials.

We are excited about the potential of this new 3D-printing technology using a portable, lightweight printer costing less than $400. We imagine that a soldier could pull this printer out of a backpack and print a chemical sensor or other electronics they need, directly on the skin. It would be like a ‘Swiss Army knife’ of the future with everything they need all in one portable 3D printing tool.

Michael McAlpine, Benjamin Mayhugh Associate Professor of Mechanical Engineering, University of Minnesota

One of the main innovations of the new 3D-printing methods is that printer can accommodate small movements of the body while printing. Temporary markers are positioned on the skin and the skin is scanned. The printer employs computer vision to handle movements in real-time.

No matter how hard anyone would try to stay still when using the printer on the skin, a person moves slightly and every hand is different. This printer can track the hand using the markers and adjust in real-time to the movements and contours of the hand, so printing of the electronics keeps its circuit shape.

Michael McAlpine, Benjamin Mayhugh Associate Professor of Mechanical Engineering, University of Minnesota

Another exclusive feature of this 3D-printing method is that it uses a specialized ink containing silver flakes, which is capable of curing and conducting at room temperature. This is unlike other 3D-printing inks that require curing at high temperatures (up to 100 °C or 212 °F) and would burn the hand.

To take off the electronics, the person can just wash it off with water or peel off the electronic device with tweezers.

Besides electronics, the new 3D-printing method paves the way for a number of other applications, including printing cells to aid those with skin ailments. McAlpine’s team collaborated with University of Minnesota Department of Pediatrics doctor and medical school Dean Jakub Tolar, a world-famous expert on treating uncommon skin disease. Using a bio-ink the team effectively printed cells on a mouse skin wound. This could facilitate advanced medical treatments for those with skin diseases.

I’m fascinated by the idea of printing electronics or cells directly on the skin. It is such a simple idea and has unlimited potential for important applications in the future.

Michael McAlpine, Benjamin Mayhugh Associate Professor of Mechanical Engineering, University of Minnesota

Besides McAlpine and Tolar, the University of Minnesota team includes Ph.D. students Zhijie Zhu and Xiaoxiao Fan and postdoctoral researcher Shuang-Zhuang Guo from the Department of Mechanical Engineering in the College of Science and Engineering; and research staff Cindy Eide and Tessa Hirdler from the Department of Pediatrics in the Medical School.

This research was sponsored by grants from the National Institutes of Health and state-funded Regenerative Medicine Minnesota. Moreover, the paper’s first author Zhijie Zhu received funding from a University of Minnesota Interdisciplinary Doctoral Fellowship.

3D printing electronics on a moving hand