Jul 30 2018

In large-scale production of food products, raw ingredients are combined together in huge stainless steel machines that cannot be cleaned easily. Repeated usage of these machines results in small grooves and scratches on their surfaces, providing a perfect place for bacteria and biofilms to hide.

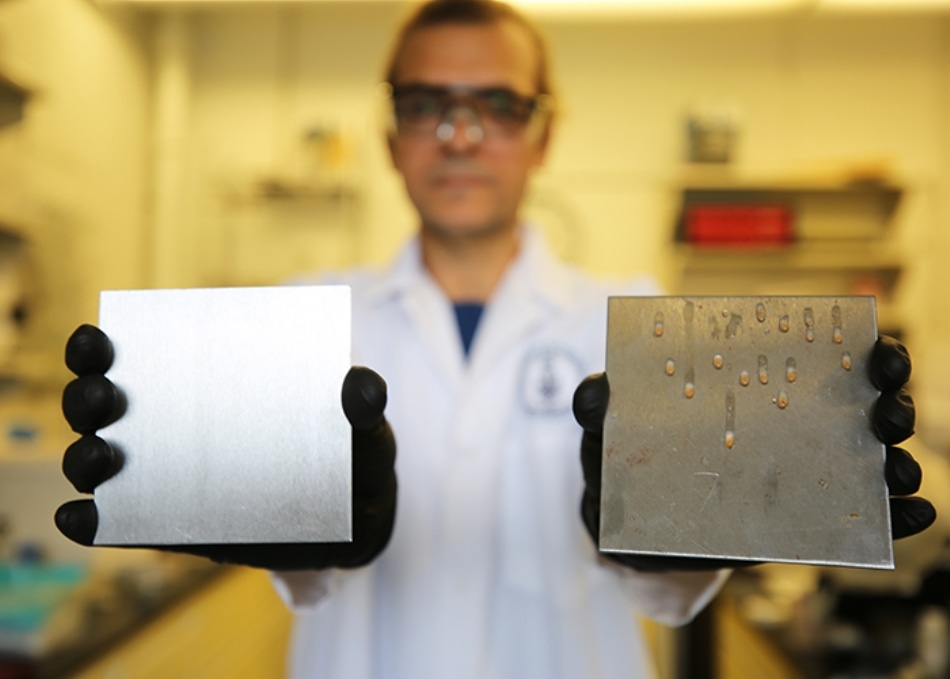

Dr. Tarek Awad, a researcher in U of T’s Department of Materials Science & Engineering, shows two samples: at left, a stainless steel surface treated to trap simple cooking oil, and at right, an uncoated surface. The uncoated surface can accumulate food residue and encourage the growth of food-borne pathogens. (Image credit: Liz Do)

Dr. Tarek Awad, a researcher in U of T’s Department of Materials Science & Engineering, shows two samples: at left, a stainless steel surface treated to trap simple cooking oil, and at right, an uncoated surface. The uncoated surface can accumulate food residue and encourage the growth of food-borne pathogens. (Image credit: Liz Do)

Although surface scratches may seem to be minute to the naked eye, they will appear like a canyon to bacteria, which measure just several micrometers in size. Bacteria and food residue trapped on the equipment surface subsequently raise the risk of contamination from microorganisms such as E. coli, Salmonella, and Listeria.

In order to prevent bacteria from thriving within these machines, Professor Ben Hatton (MSE), Dr. Dalal Asker and Dr. Tarek Awad explore safer, cheaper, and more effective methods. Such methods reduce the risk of cross contamination, which can cause foodborne disease. Their team has suggested a new, simple solution, which involves trapping a thin layer of cooking oil at the surface of the metal to fill in minute cracks, scrapes, and fissures and thus create a barrier that prevents bacteria from attaching to the surface.

The researchers observed that this new method resulted in as much as 1,000 times reduction in the levels of bacteria present inside the tested industrial machines. Their study has been reported in the journal ACS Applied Materials & Interfaces.

“Coating a stainless steel surface with an everyday cooking oil has proven remarkably effective in repelling bacteria,” states Hatton who teamed up on the project with an Ontario seed processing company - AGRI-NEO - which was looking for a solution to a mutual problem in its industry. “The oil fills in the cracks, creates a hydrophobic layer and acts as a barrier to contaminants on the surface.”

This alternative is both simple and cost-effective and is based on the principle of Slippery Liquid-Infused Porous Surfaces (SLIPS), which was originally developed at Harvard in order to trap lubricant layers into a surface microstructure and produce slippery, non-adhesive, and non-wetting properties. A safer option is also provided by cooking oils such as corn, olive, or canola for cleaning food-processing machines when compared to the aggressive disinfectants and chemicals that are generally utilized. The machine’s sheer size makes it more difficult for the cleaning materials to do a methodical job, and the remaining bacteria can also develop resistance against the cleaning agents.

In the Hatton’s method, which involves filling the microscopic scratches with oil, bacteria are prevented from settling and the surface is cleaned without leaving any residues of chemicals on the surface of stainless steel.

Contamination in food preparation equipment can impact individual health, cause costly product recalls and can still result after chemical-based cleaning occurs. The research showed that using a surface treatment and a cooking oil barrier provides greater coverage and results in 1,000 less bacteria roaming around.

Professor Ben Hatton

Novel combinations of foods, oils, and biofilm types are being tested by the Hatton research team to boost the efficiency of the bacteria barriers. The researchers will also investigate the options of using this technique in developing countries to reduce bacterial infection and thus enhance mortality rates.

Food particles can accumulate on an untreated stainless steel surface, at left, increasing the risk of contamination in food production facilities. The oil-treated surface, at right, repels material. (Image credit: Liz Do)