Feb 15 2019

A*STAR scientists have demonstrated, through theoretical calculations, that it may be possible to fabricate thermoelectric organic polymers that can convert heat into electrical energy with high efficiency.

Thermoelectric Materials- Characteristics

Thermoelectric (TE) materials work by responding to temperature differences, inducing electric charge carriers to flow from the hot to the cold side of the material. TE materials are already used for powering refrigeration, and for limited power generation. An effective TE material needs to have high electrical conductivity, low thermal conductivity, and a high ‘Seebeck coefficient’ – the voltage generated per degree of temperature difference across the material. However, it is rare for any one material to satisfy all of these conditions, meaning that existing TE materials are limited in efficiency.

Improving TE Performance

“One way of improving TE performance is to use doping, adding certain chemicals to the material to enhance its electrical conductivity by increasing charge carrier concentrations,” says Shuo-Wang Yang, at A*STAR’s Institute of High Performance Computing, who led the team. “However, doping can also interfere with the materials’ stability and performance, and finding a dopant that works effectively is challenging. Identifying TE materials that work without doping could transform energy harvesting.” The team focused their attention on linear-backbone coordination polymers, structures containing metal ions linked by ligands, which can be built in the laboratory to specific designs. These polymers exhibit numerous advantages over conventional inorganic TE materials; they are flexible, have low thermal conductivity and are compatible with biological organisms. However, they have low electrical conductivity – a challenge that Yang and co-workers tried to overcome in their theoretical search.

Poly (Nickel-Ethylenetetrathiolate)

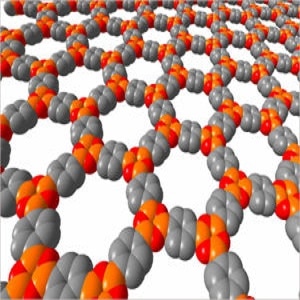

“Based on first-principle molecular dynamics and structure optimization, we identified a polymer called poly (nickel-ethylenetetrathiolate) and three associated analogs which demonstrate intrinsically metallic behaviors and high electrical conductivity,” says Yang. “This is exciting as it suggests these polymers are potential dopant-free TE materials.” The team’s analyses suggest that this metallic behavior stems from the formation of dense, non-bonding molecular interactions between sulfur or selenium atoms within the polymeric structures. These interactions strengthen the forces between the atoms, decreasing electronic band gaps and encouraging the flow of electrical charge.

“Xu Jianwei, Kedar Hippalgaonkar, and their teams at the A*STAR Institute of Materials Research and Engineering are now synthesizing these polymers,” says Yang. “These materials are very promising, particularly in the applications of waste heat recovery and refrigeration near ambient temperature.”