Jul 19 2019

Steering wheels tend to get too hot to touch during the summer. A new thermoelectric material described in the journal Science could soon be the solution.

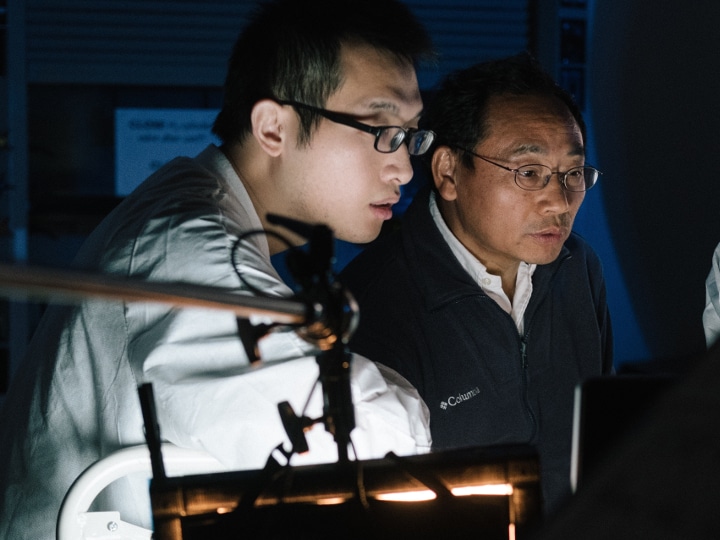

Texas Center for Superconductivity at UH Director Zhifeng Ren, right, and post-doctoral researcher Jun Mao say a new thermoelectric cooling material is inexpensive to produce and works efficiently at room temperature. (Image credit: University of Houston)

Texas Center for Superconductivity at UH Director Zhifeng Ren, right, and post-doctoral researcher Jun Mao say a new thermoelectric cooling material is inexpensive to produce and works efficiently at room temperature. (Image credit: University of Houston)

The extensive acceptance of thermoelectric devices that can directly turn electricity into thermal energy for heating and cooling has been slowed down, partly, by the shortage of materials that are both economical and highly efficient at room temperature.

Currently, scientists from the University of Houston and the Massachusetts Institute of Technology report the discovery of a new material that functions efficiently at room temperature while requiring virtually no expensive tellurium, a key component of the present advanced material.

The research, illustrated in a paper published online by Science on July 18th, 2019 has promising applications for keeping vehicles, electronic devices, and other components from overheating, said Zhifeng Ren, corresponding author on the research and director of the Texas Center for Superconductivity at UH, where he is also M.D. Anderson Professor of Physics.

We have produced a new material, which is inexpensive but still performs almost as well as the traditional, more expensive material.

Zhifeng Ren, Study Corresponding Author and Director, Texas Center for Superconductivity, UH

The scientists say further work could bridge the minor performance gap between their new material and the traditional material, a bismuth-tellurium based alloy.

Thermoelectric materials function by manipulating the flow of heat current from a warmer part to a cooler part, and thermoelectric cooling modules work according to the Peltier effect, which defines the transfer of heat between two electrical junctions.

Thermoelectric materials can also be used to convert waste heat—from automobile tailpipes, power plants, and other sources—into electricity, and several new materials have been reported for that application, which requires materials to work at much higher temperatures.

Thermoelectric cooling modules have posed an immense challenge because they have to function at cooler temperatures, where the thermoelectric figure-of-merit, or ZT, is low because it is reliant on temperature. The figure-of-merit is a metric used to establish how efficiently a thermoelectric material performs.

Regardless of the challenge, thermoelectric cooling modules also, at least for the time being, provide more commercial potential, partly because they can work for a long lifecycle at cooler temperatures; thermoelectric power generation is complex by issues linked to the high temperatures at which it works, including thermal instability and oxidation.

The market for thermoelectric cooling is expanding. “The global thermoelectric module market was worth ~0.6 billion US dollars in 2018 and it is anticipated to reach ~1.7 billion US dollars by 2027,” the scientists wrote.

Bismuth-tellurium alloys have been known to be the top-performing material for thermal cooling for several years, but the scientists said the high cost of tellurium has restricted extensive use. Jun Mao, a post-doctoral researcher at UH and the paper’s first author, said the cost has reduced in recent times but is still about $50/kg. That compares to about $6/kg for magnesium, a major component of the new material.

Along with Ren and Mao, the other authors on the paper include Hangtian Zhu, Zihang Liu, and Geethal Amila Gamage, all of the UH Department of Physics and TcSUH, and Zhiwei Ding and Gang Chen of the Department of Mechanical Engineering at the Massachusetts Institute of Technology.

They stated that the new material made up of bismuth and magnesium and created in a form possessing a negative charge, called n-type, was nearly as efficient as the traditional bismuth-tellurium material. That, pooled with the lower cost, should multiply the use of thermoelectric modules for cooling, they said.

To create a thermoelectric module with the new material, scientists integrated it with a positive-charge carrying, or p-type, version of the traditional bismuth-tellurium alloy. Mao said that enabled them to use just half as much tellurium as most existing modules.

Since the cost of materials makes up for about one-third of the cost of the device, that savings adds up, he said. Furthermore, the new material maintains electrical contact more effectively than the majority of nanostructured materials, the scientists stated.