Jan 24 2020

One fact that has been understood for many years is that water repellency is required for surfaces to clear the buildup of condensation—just like water droplets that develop in power plant condensers to decrease the buildup of pressure.

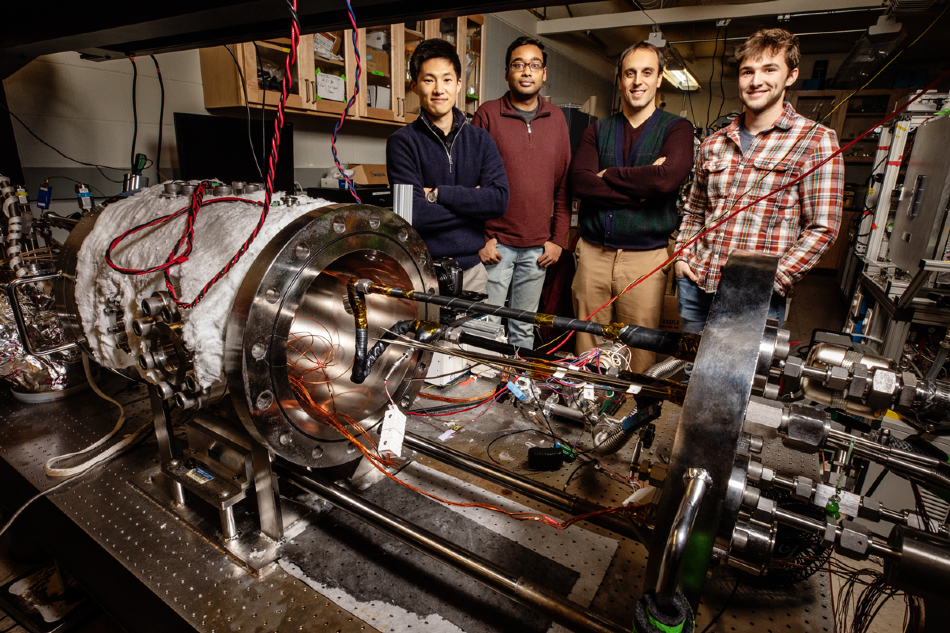

Graduate student Hyeongyun Cha, postdoctoral researcher Soumyadip Sett, professor Nenad Miljkovic, and undergraduate student Stephen Bosch are challenging an age-old theory about the processes that control the clearing of water condensation from surfaces. Image Credit: L. Brian Stauffer.

Graduate student Hyeongyun Cha, postdoctoral researcher Soumyadip Sett, professor Nenad Miljkovic, and undergraduate student Stephen Bosch are challenging an age-old theory about the processes that control the clearing of water condensation from surfaces. Image Credit: L. Brian Stauffer.

But according to a new study, the need for water repellency is still vague and the slipperiness that exists between the solid surface and the water droplets seems to be more crucial for shedding condensation.

Such advancements hold implications for the costs involved in power generation as well as technologies such as de-icing surfaces required in aircraft and power lines.

The study was jointly headed by Nenad Miljkovic, a mechanical sciences and engineering professor from the University of Illinois, and Arun Kota, a mechanical and aerospace engineering professor from North Carolina State University. The study results were published in the Science Advances journal.

In several industrial and natural systems, heat transfer typically takes place via condensation. According to the scientists, when the vapor condenses onto a surface in the form of droplets instead of films, such kinds of energy transfer can occur most efficiently.

The water droplets should be mobile so that the surface remains clear for efficient and continuous transfer of energy, and a slippery surface, in this regard, helps quite significantly.

One aspect of science that has not been assessed lately is the way condensing droplets develop and coalesce at the time of condensation, stated Miljkovic.

The scientists assumed that the condensing surface is no longer applicable when the surface has to be maintained clear of water droplets, which is contrary to the established thought. A condensing surface is known as nonwetting or wetting, based on its potential to repel or attract water.

Kota’s research team tested this concept by creating a special solid surface that is both slippery and wetting to water droplets. “This is counter-intuitive, because droplets tend to stick to wetting surfaces and do not easily slip or slide on them,” stated Kota.

Using time-lapsed images of droplets that form on these special solid surfaces, Miljkovic’s research team successfully quantified the contact angle between the surface and the droplets, and counted the number of water droplets that were present in a different range of sizes as the droplets coalesce.

We found that when solid surfaces are slippery, condensed droplets will coalesce with surrounding droplets and shed off of the surface, whether we are dealing with a wetting or nonwetting surface.

Arun Kota, Professor, Department of Mechanical and Aerospace Engineering, North Carolina State University

Such an observation suggests that a wider range of materials can be used as condensation surfaces, and not just water-repellent materials alone.

Instead of using specialized polymer surfaces, which are difficult to adhere to metal and only last a few months, power plants may be able to use a more durable wetting materials for water shedding, such as ceramic or metal that has been engineered to be slippery and could last 10 years or longer.

Nenad Miljkovic, Professor, Department of Mechanical Sciences and Engineering, University of Illinois

Miljkovic continued, “This same concept is valuable in other applications, too, like coming up with new de-icing surfaces for aircraft wings and power lines and water-shedding coatings for building energy applications, ventilation and conditioning systems.”

The scientists further stated that the development of new slippery and wetting solid materials for use in condensation surfaces is inherent with certain challenges that need to be resolved. Apart from that, the materials have to be texturally and chemically even, which can still prove to be very costly, they added.

This work not only demonstrates a previously unexplored idea of using well-engineered durable and wetting solid surfaces to achieve high droplet mobility, but also provides new insight to the fundamental scientific theory behind condensation.

Nenad Miljkovic, Professor¸ Department of Mechanical Sciences and Engineering, University of Illinois

The study was supported by International Institute for Carbon-Neutral Energy Research, the Office of Naval Research, National Institutes of Health, and the National Science Foundation.