Researchers have recently proposed a novel soluble Troger’s base (TB)-PIM polymer for fuel cells, with top-notch dimensional stability and mechanical properties, published in the journal ACS Applied Energy Materials.

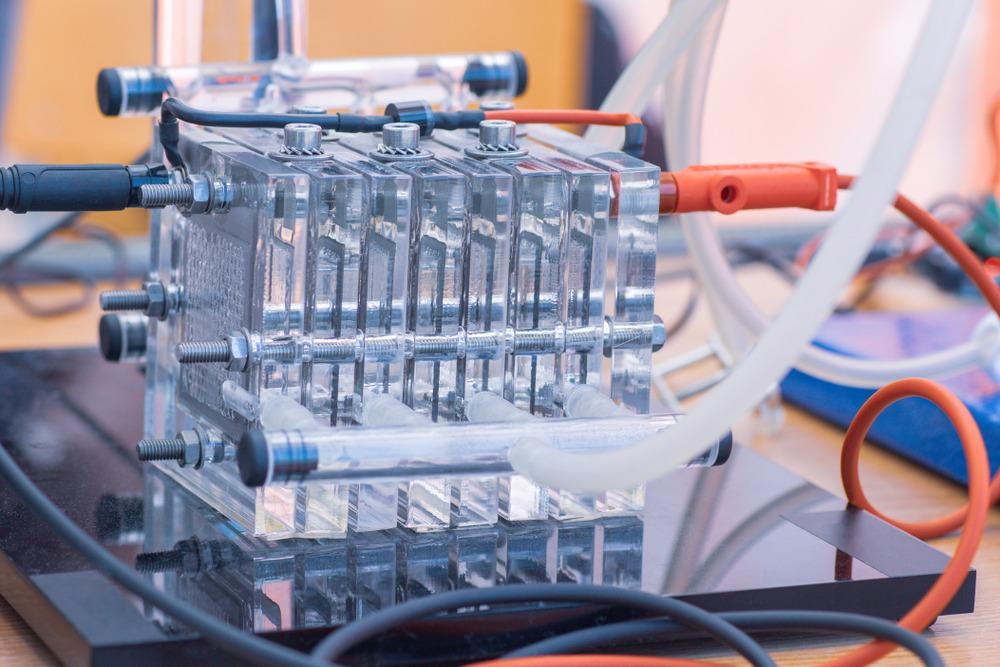

Study: Polymer Electrolyte Membranes from Microporous Troger’s Base Polymers for Fuel Cells. Image Credit: Kaca Skokanova/Shutterstock.com

According to the latest study, with the aggressive growth of renewable energy, electrolytic technologies, such as fuel cells, offer excellent applicability potential for renewable energy.

A Comparison of PEMFC and AEMFC

According to the study, industrial commercial membranes for proton exchange membrane fuel cells (PEMFCs) are perfluorosulfonic acid membranes (such as Nafion). Compared to PEMFCs, the anode exchange membrane fuel cells (AEMFCs) have the great benefit of functioning at high pH, which is useful as it offers a significantly less toxic and corrosive environment.

Troger’s Base (TB)

Tröger's Base (TB) is a V-shaped bridging carbocyclic reactive diamine with an intrinsic nanoporous topology due to poor compaction of the helical polymerization, allowing for ion transportation.

Xu et al. created unsubstituted Tröger's base PIM AEMs with significant hydroxide conduction of 164.4 mS/cm at 80 °C and a low IEC value (0.82 mmol/g).

Materials Used

The researchers utilized 4-(2-Hydroxyethoxy)-1,3-phenylenediamine dihydrochloride (HEPD, 99%), ammonium hydroxide solution (25-28%), 4,4’-diamine-3,3’-dimethyl-biphenyl (DMBP, 98%), trifluoroacetic acid (99%), and iodoform (99%) for the synthesis of novel technology for fuel cells.

Methods Incorporated in Research

The latest research reveals that the first step was the synthesis of the DMBP-TB copolymer. A standard DMBP-TB polymerization method was followed which after cooling 10 mmol (2.124 g) of DMBP and 50 mmol (3.805 g) of DMM to near 0 °C, TFA (20 mL) was administered by releasing to maintain mixing for 0.5 h.

The next essential step was the HEPD/DMBP-TB copolymer synthesis. It involved the addition of 2mmol (0.482 g) of HEPD, 8mmol (1.698g) of DMBP in 50mmol (3.805 g) of DMM contained in a three-necked flask.

More on Fuel Cells - A Proton Exchange Membrane Fuel Cell Able to Run on CO and H2

This was followed by the synthesis of DMBP-QTB and HEPD/DMBP-QTB manufacturing. To synthesize PE membranes, DMBP-TB and HEPD/DMBP-TB copolymers were solubilized in an NMP mixture to create a homogenous solution at 60 °C. All these essential steps were the prerequisites of the experiment to carefully assess the properties of TB-PIM polymers for fuel cells.

Research Findings

The research showed that the synthesized polymers were soluble in general solvents. The variations in inherent porous structure between these two TB-based polymers are mostly due to lattice topology. DMBP-TB had a BET surface area of 353 m2/g, whereas HEPD/DMBP-TB had a surface area of 7.38 m2/g. All of the generated samples had a thick and homogenous structure, revealing that the TB-based membranes are completely sealed and acceptable for use in fuel cell technology.

Mechanical Properties of TB-PIM Polymer

The researchers also investigated the mechanical properties of the novel synthesized polymer. The research showed that at 25 °C, the synthesized film absorbed water in the following order: HEPD/DMBP-QTB > DMBP-QTB > HEPD/DMBP-TB > DMBP. So, HEPD/DMBP-TB absorbed much more water than DMBP-TB.

The tensile strength (59.6 MPa) and elongation at rupture of DMBP-TB were both high (3.6 percent ). HEPD/DMBP-TB has a tensile strength of 53.8 MPa and an elongation at a break of 4.2 percent. The tensile strength of the HEPD/DMBP-QTB AEM after quaternization was 48.5 MPa, and the elongation at break was 4.4 percent.

Stability and Conductivity Findings

The study has revealed that after 24 hours of immersion in 1 M H2SO4 mixtures, the proton conductivity of the DMBP-TB membrane was 16.5 mS/cm at 30 °C and 42.5 mS/cm at 80 °C. As opposed to it, at 30 °C, the HEPD/DMBP-TB membrane had a greater proton conductivity of 26.8 mS/cm, which climbed to 58.3 mS/cm at 80 °C.

In addition to the porous medium, the TB unit offers a compact and periodic concentration of cationic groups, allowing OH- to be delivered by vehicles and Grotthuss processes simultaneously, enhancing OH- conductivity.

Performance Analysis

Individual cells with DMBP-QTB and HEPD/DMBP-QTB AEMs had high open-circuit voltages of 0.939 and 0.934 V, showing that the TB membrane efficiently prevents gas cross-penetration.

Under identical circumstances, the maximum power density of an individual cell using the HEPD/DMBP-QTB AEM was 76.6 mW/cm2, which was greater than the DMBP-QTB AEM (68.3 mW/cm2).

Individual cells treated with the HEPD/DMBP-QTB AEM performed more efficiently than those treated with the DMBP-QTB AEM, which might be attributed to the HEPD/DMBP-QTB AEM's increased hydroxide conduction.

In short, the research has shown that the TB polymers with stiff and coiled backbones have outstanding dimensional stability, mechanical characteristics, and thermal stability, as well as the capacity to produce subnanometer cavities that allow for fast ionic conduction.

Thus, it wouldn’t be wrong to say that further studies into membrane technology based on the TB framework are needed to increase their electrochemical performance and single-cell efficiency.

References

Du, X., Yuan, Y., Dong, T., Chi, X., & Wang, Z. (2021). Polymer Electrolyte Membranes from Microporous Troger’s Base Polymers for Fuel Cells. ACS Applied Energy Materials. https://pubs.acs.org/doi/abs/10.1021/acsaem.1c03025

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.