Researchers in the Netherlands have recently developed a straightforward and reliable ultrasonic spray method for industrial fabrication of piezoelectric Poly (Vinylidene Fluoride) Films (PVDF) films which can be used for the fabrication of large-scale piezoelectric films while eliminating intensive poling or stretching processes.

Study: Fabrication of Poly (Vinylidene Fluoride) Films by Ultrasonic Spray Coating; Uniformity and Piezoelectric Properties. Image Credit: Dinga/Shutterstock.com

The research was published in the journal Materials & Design.

PVDF films are highly non-reactive thermoplastic fluoropolymers a polymer of vinylidene fluoride. PVDF films typically find application in applications that demand the highest purity, strength, and resistance to solvents, acids, and heat.

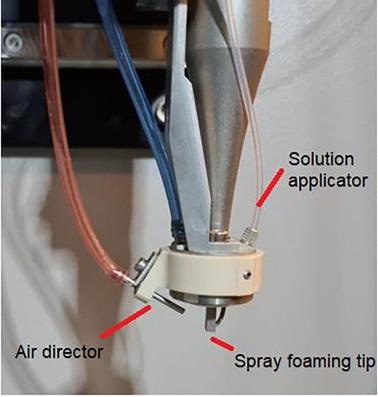

Nozzle-less ultrasonic spray coating system head. Image Credit: Taleb, S et al., Materials & Design

Therefore, have found application across a wide range of fields and disciplines including a primary focus on polymer chain structure, fabrication methods, piezoelectric properties, mechanical strength, and sensor, actuator, energy harvesting applications.

When poled, PVDF is a ferroelectric polymer, demonstrating effective piezoelectric and pyroelectric properties. These characteristics make it particularly useful in sensor and battery applications.

More recently, ferroelectric PVDF-TrFE films have found application in nano-electric devices including nonvolatile memories, photodetectors, field-effect transistors, and PVDF composites are used for electric accessories and embedded capacitors.

Fabrication Methods

Common methods for the fabrication of PVDF films include spin coating, electrospinning, and casting methods. However, as coating and casting methods typically require post-processing in the form of stretching, poling, or quenching to achieve a polar phase they are not scalable and limit large-scale fabrication.

The Dutch team identified electrospray deposition (ESD) and spray coating methods as emerging techniques for PVDF film fabrication with certain advantages such as low-cost, good uniformity over large surface areas, and rapid processing times.

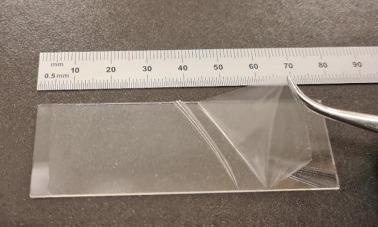

A PVDF film made by USC method. Image Credit: Taleb, S et al., Materials & Design

With the addition if ultrasonic technology, the researchers believe these benefits could be enhanced. Hence, they developed a nozzle-less ultrasonic spray coating system capable of fabricating freestanding PVDF films with enhanced piezoelectric properties.

“The advantage of this system over conventional spray systems is the enhanced uniformity of the final film due to the atomization of the liquid and formation of smaller droplets provided by the mechanical vibration,” explained co-author Monica Acuaulta Assistant Professor at Faculty of Science and Engineering, the University of Groningen.

The flexibility of the system opens up the possibility to fabricate devices with complex designs and shapes as well as the potential to use a variety of substrates materials. The ability to apply piezoelectric PVDF films to a wider array of substrates opens up its application to more innovative technologies.

Ultrasonic Fabrication

To apply the PVDF films the team used a nozzle-less ultrasonic spray coating (USC) system (PRISM-400-BT) to fabricate piezo-polymer films 5 and 9 um thick. The Prism-400-BT system allowed the team to closely control air pressure, solution flowrate, tip distance, and substrate temperature.

The ultrasonication also facilitated atomization of the liquid phase while air pressure directed the liquid droplets to the hot bench where a glass substrate was placed for the application of PVDF films.

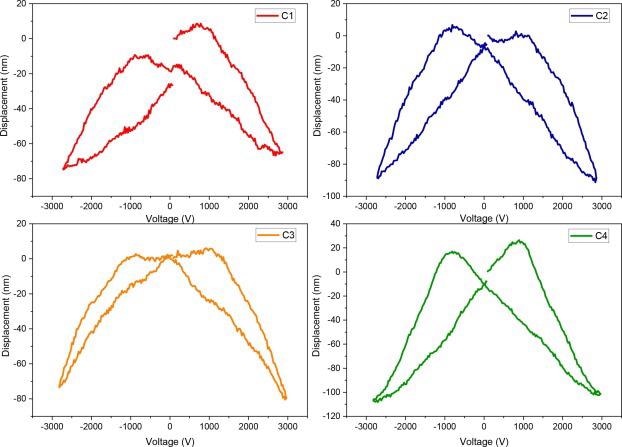

This ultrasonic spray coating system proved successful for the fabrication of pure PVDF films with a high piezoelectric coefficient (d33 = 48 pm/V). Furthermore, highly crystalline (56 %) PVDF films with predominant β phase for flexible and transparent engineering devices are achieved without the need for a post-processing step.

The researchers also identified that film uniformity was a key factor in achieving piezoelectric properties and improving the piezoresponse in the PVDF film. The ultrasonic spray coating method proved to be a simple and reliable method for achieving high uniformity.

Displacement-voltage (strain) loops for PVDF films made at conditions C1-4. Image Credit: Taleb, S et al., Materials & Design

“The obtained d33 value, in the range of those usually obtained by expensive PVDF-TrFE films, brings us to the conclusion that USC method is capable of producing large-scale, low-cost, and high-quality piezoelectric films in one step,” says Acuaulta.

Additionally, the USC system enables the fabrication of flexible and wearable electronics with complex design composition on a wide variety of substrate materials, further expanding its application to more advanced technologies.

Thus, USC is a promising method opening up the possibility for the use of high-quality pure PVDF films across a variety of industries and large-scale engineering applications.

Single-Step Innovation

In recent years, PVDF films have attracted significant interest in the fabrication of piezoelectric devices due to the fact they possess high sensitivity, mechanical flexibility, multi-technology compatibility, and stability.

Several studies have been conducted on piezoelectric PVDF for energy, environmental, and biomedical applications as well as finding use in nano electrical devices. Traditional methods used for the fabrication of PVDF films such as spin coating and casting have the drawbacks of the necessity of additional treatment (poling or mechanical stretching) to improve the piezoelectricity of the material.

However, the Dutch team demonstrated that there may be a better way to produce PVDF films with piezoelectric properties: “We proved that the ultrasonic spray coating method is capable of producing large-scale, low-cost PVDF films in a single step,” Acuaulta declared.

References

Taleb, S., Badillo-Ávila, M.A., Acuautla, M., Fabrication of Poly (Vinylidene Fluoride) Films by Ultrasonic Spray Coating; Uniformity and Piezoelectric Properties, Materials & Design (2021). https://www.sciencedirect.com/science/article/pii/S0264127521008285?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.