Designing advanced materials that can withstand extreme environments within fusion reactors is key to the development of this technological field. To investigate the development of new zirconium alloys that meet the structural demands in fusion reactor design, a research paper has been published in the Journal of Nuclear Materials.

Study: High Temperature Zirconium Alloys for Fusion Energy. Image Credit: Efman/Shutterstock.com

Materials and Fusion Reactor Design

Nuclear fusion has been extensively investigated in recent years due to its ability to create clean energy without the proliferation of radioactive byproducts. In fusion, two elements are fused together to release energy. Currently, the best candidate for fusion is a deuterium-tritium reaction. Deuterium and tritium are two isotopes of hydrogen, which when fused create helium, free neutrons, and energy. Currently, designs being evaluated for fusion reactors are DEMO, STEP, and ITER.

In a fusion reactor, the neutron efficiency challenges are different from fission reactions. Tritium must be constantly replenished to sustain the long-term efficiency of the fusion reaction. This is accomplished by breeding the tritium via inelastic neutron scattering. As the reactions occur at elevated temperatures and are subject to thermal creep, materials that can perform well at elevated temperatures whilst maintaining a low thermal neutron cross-section are required.

![Neutron cross-section for 6Li breeding T (blue solid line), 56Fe non-elastic scattering (red dotted line), 90Zr non-elastic scattering (black dashed line). Data and references used to contruct figure can be found in Ref. [8].](https://www.azom.com/images/news/ImageForNews_57575_16387907867531911.jpg)

Neutron cross-section for 6Li breeding T (blue solid line), 56Fe non-elastic scattering (red dotted line), 90Zr non-elastic scattering (black dashed line). Image Credit: King, DJW et al., Journal of Nuclear Materials

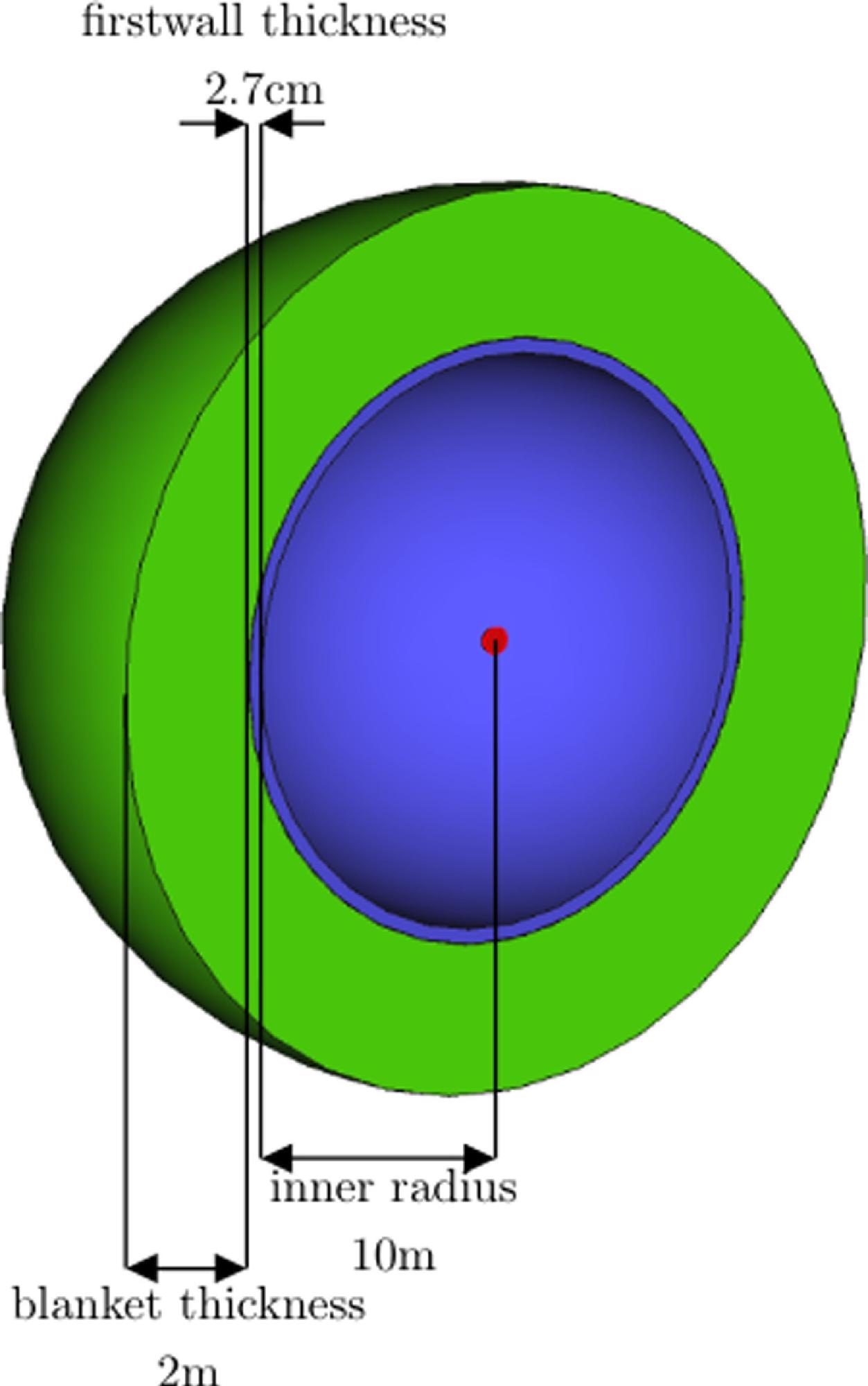

The selection of materials with superior structural and thermal properties is essential for the safe and optimal design of fusion reactor components. A key element of fusion reactor design is the breeder blanket, which shields the reactor instruments from radiation. Breeder blankets are composed of a set of modules that cover the interior of the fusion reactor vessel and must withstand extreme temperatures and intense neutron fluxes. Additionally, it ensures maximum reactor efficiency.

Materials that have been explored as candidates for breeder blanket design include vanadium, iron, silicon, and chromium-based alloys and composites. Recent studies have demonstrated that zirconium (Zr) is an advantageous candidate if used as a structural material in the first wall of a breeder blanket in a DEMO-like reactor.

Advantages of Zirconium

Zirconium has already been used as a material in fission reactor applications for approximately six decades. Today, many zirconium alloys are used as fuel claddings and assemblies in light water fission reactors. Common alloys include Zr-2.5, ZIRLOTM, and Zircaloy-2 and –4. The success of these alloys has largely been due to the small cross-section of their thermal neutron absorption, relative to other structural material elements.

The advantage of a small thermal neutron absorption cross-section is that it allows the higher availability of neutrons, which sustains the fission reaction’s criticality. Other materials need further enrichment, which can be financially costly. However, as fusion reactions occur at elevated temperatures and there is an inherent thermal creep that occurs during operation, current zirconium alloys are insufficient.

Cross-section of the simple sphere geometry (not to scale) where the breeder blanket (outer sphere), surrounds the first wall (inner circle) and is separated from the neutron point source (middle circle) by a vacuum. Image Credit: King, DJW et al., Journal of Nuclear Materials

Investigating Current Zirconium Alloys and Addressing Issues

In the study published in the Journal of Nuclear Materials, the authors have investigated several currently commercially available zirconium alloys including binary alloys such as Zr-V and Zr-Si alloys, as well as higher-order alloys such as Zr-Nb-Ti and Zr-Mo-Sn. It was concluded that with further research, higher-order alloys could show advantageous thermal and structural properties (such as strength and ductility) whilst maintaining a low thermal neutron cross-section.

However, currently, there is incomplete data on the performance of these alloys under elevated temperatures that occur during operation. In a fusion reactor, temperatures could easily reach as high as 500-700 oC. Any structural material composed of zirconium alloys would be expected to display superior thermal and mechanical properties when used in liquid metal or helium-cooled breeder blankets.

Investigating the currently available zirconium alloys, the authors concluded that using Zr-4 as a breeder blanket structural material would markedly improve the tritium breeding ratio. Whilst this is significantly better than other candidates such as V-4Cr-4Ti, there are still issues with strength, thermal creep resistance, and fatigue properties under elevated temperatures. Moreover, impurities can cause embrittlement issues, facilitating the need for barrier coatings.

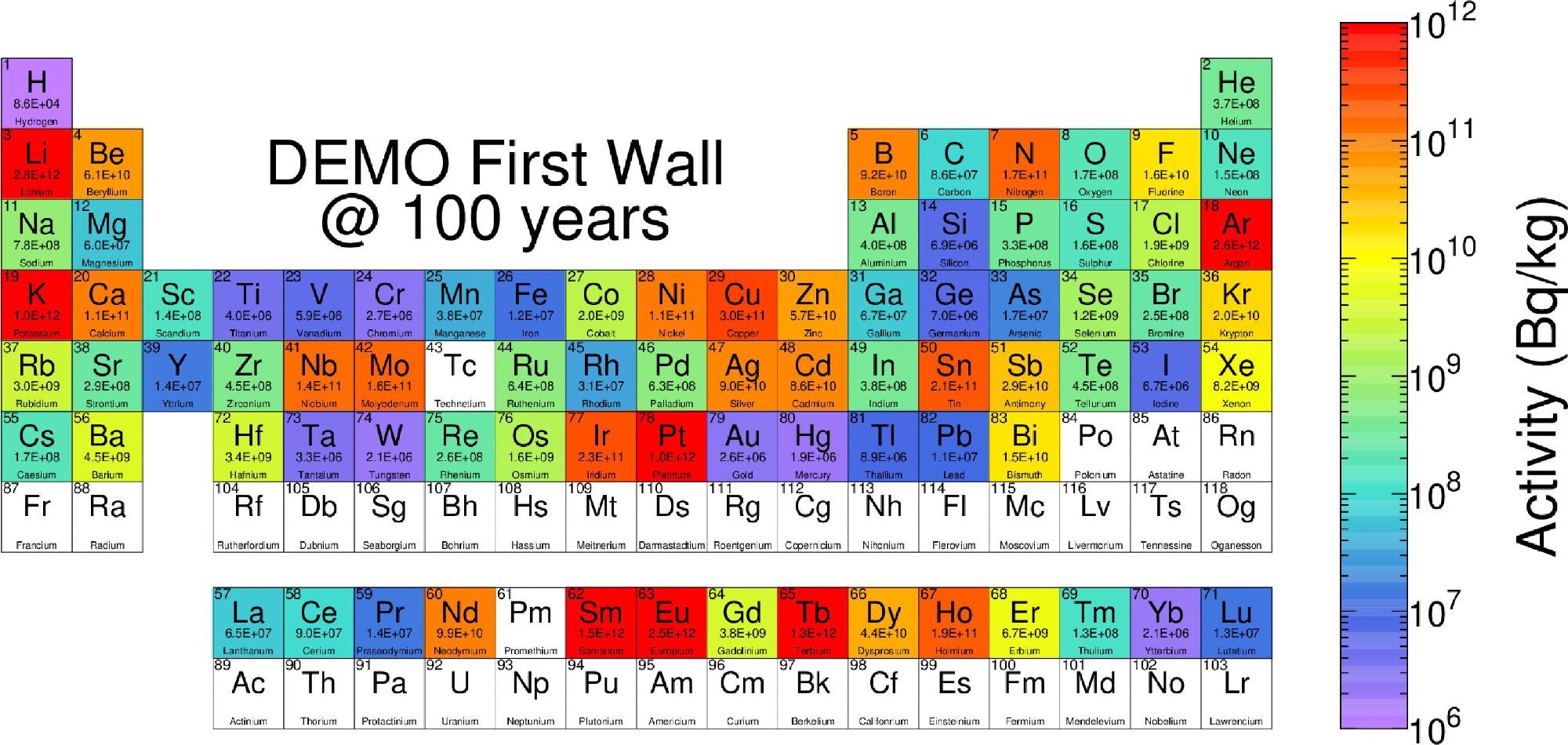

Periodic table showing the total becquerel activity from each element after 100 years of decay cooling following a 2 full power year irradiation in a DEMO firstwall environment. The colour of each element reflects the activity according to the Bq∙kg−1 legend, but the absolute values are also given beneath each element symbol. Image Credit: King, DJW et al., Journal of Nuclear Materials

Additional issues occur with candidate zirconium alloys such as poor corrosion resistance in aqueous environments and ductility issues in unpolished components. Although some alloys investigated displayed good room temperature performance such as ductility and high strength and resistance to softening caused by elevated temperature, the study concluded that to address the shortcomings any further development should include alloying of other species such as Nb, O, Al, and Sn.

Furthermore, the authors conclude that it may be difficult to produce a Zr alloy that meets both the mechanical properties and nuclear waste production requirements of fusion reactor breeder components. To harness the zirconium alloy’s neutron efficiency advantage for tritium breeding will require a “low as reasonably practicable” approach. Moreover, the authors stated that further cost-benefit analysis of zirconium materials for tritium breeder blankets is required.

Further Reading

King, DJW et al. (2021) High Temperature Zirconium Alloys for Fusion Energy [online] Journal of Nuclear Materials | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S0022311521006516

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.