The rising urgency to make industry and commerce more sustainable and efficient has also spread to the construction sector. One example of this shift has manifested as increased interest in the use of recycled and repurposed waste materials for new construction applications.

Study: Influence of Iron Filing Waste on the Performance of Warm Mix Asphalt. Image Credit: senia Soboleva/Shutterstock.com

A new paper presented in the Sustainability journal has evaluated one such example of this growing trend – the use of recycled materials in the construction of asphalt concrete pavement.

Beyond their improved sustainability and relative environmental friendliness, the use of recycled materials for construction projects also offers notable financial savings in terms of raw material and waste disposal costs.

The paper reports specifically on the use of iron filling waste – a common mechanical milling waste – and its use as an alternative fine aggregate for the warm mix asphalt used in pavements in towns and cities around the world.

This particular application is especially important to the sustainability of the construction industry and the built environment in general because pavement construction consumes a vast amount of natural resources; particularly asphalt concrete which is estimated to be employed in 95% of roads and highways globally. Aggregates – typically natural sand - generally make up almost 95% of asphalt concrete’s total weight.

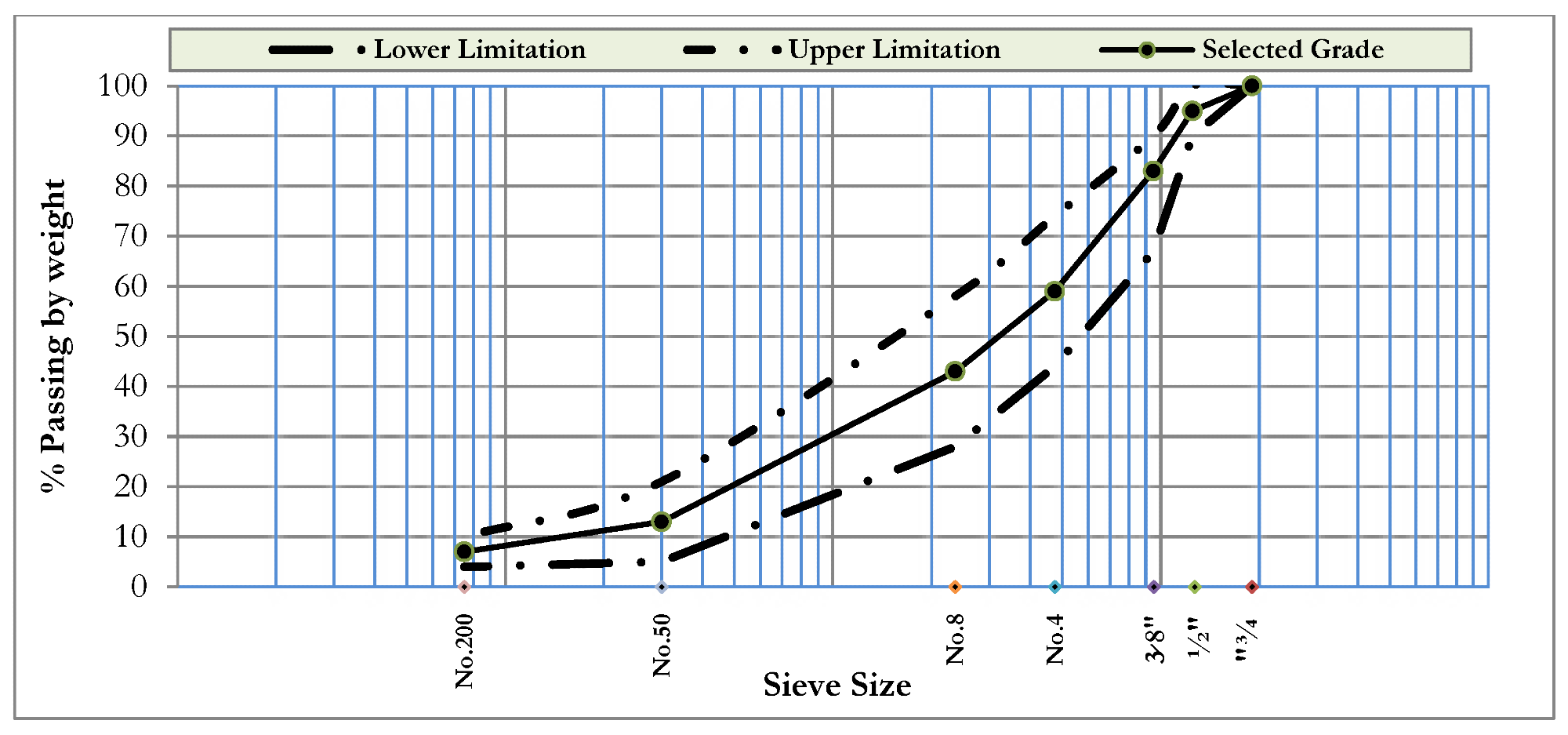

Aggregate grading for wearing layer. Image Credit: Wang, Y et al., Sustainability

Their widespread use has led to severe depletion of the natural resources required to manufacture asphalt concrete, prompting the demand for alternative sources of raw materials, not least recycled aggregates such as ceramics, broken-up concrete, and steel slag.

Iron filing waste represents a further viable option for a recycled aggregate, offering high strength, excellent durability, and a widely available supply from local factories and workshops.

In order to comprehensively evaluate the suitability of iron filing waste as the aggregate in asphalt concrete, the authors prepared five asphalt mixes by replacing specific percentages of the mixes’ aggregate with iron filing waste: 0%, 25%, 50%, 75%, and 100%. These mixtures were prepared in a similar manner to conventional concrete mixes.

With samples in place, each mixture was subjected to a range of tests to establish its mechanical properties and resilience; for example, the Marshall Test, resilient modulus tests, permanent deformation tests, flexural fatigue, and moisture susceptibility.

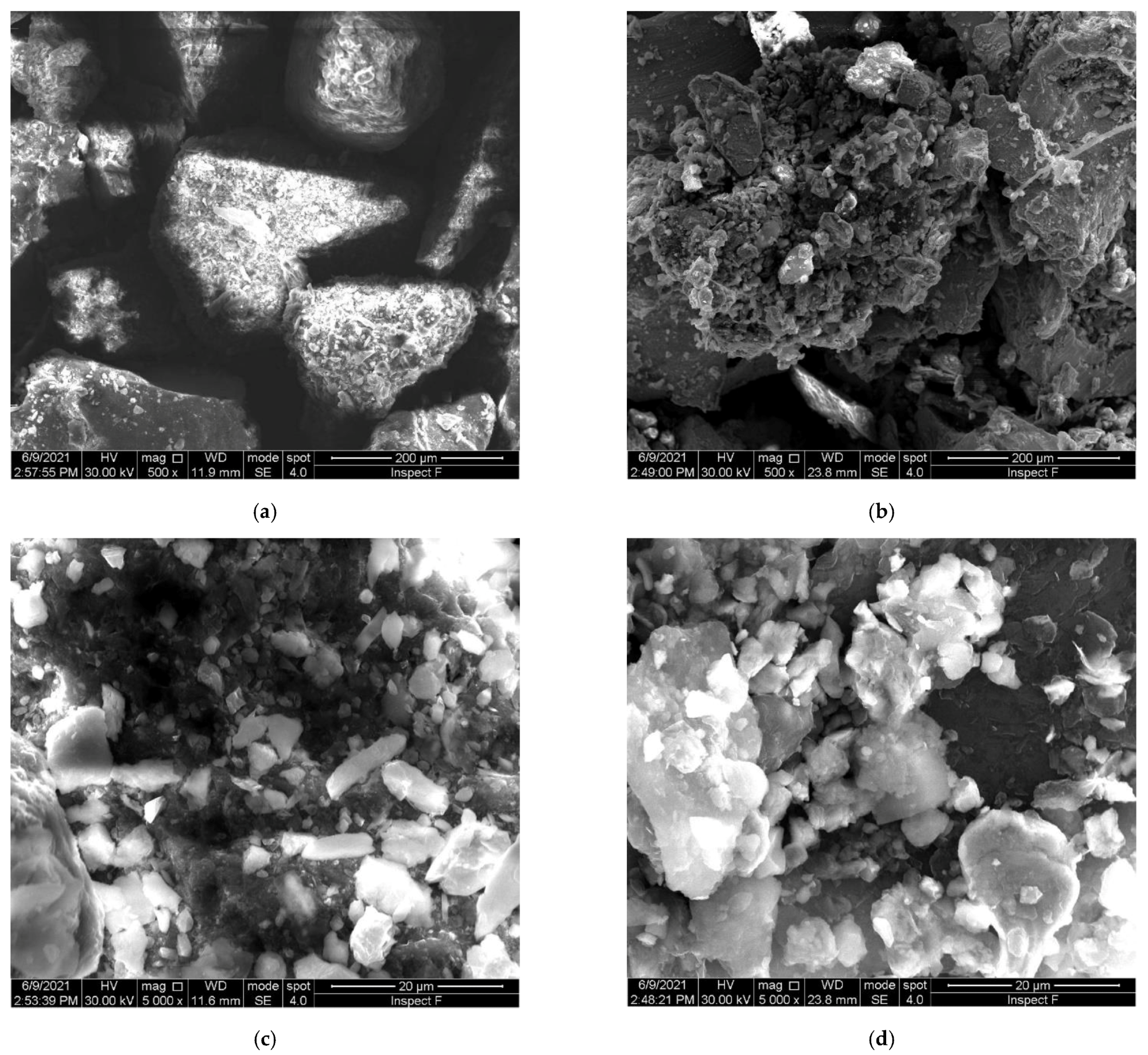

Scanning electron microscopy proved a useful tool in analyzing both the iron waste filings and the natural sand components of the warm mix asphalt, with images revealing distinct morphological characteristics and crystalline structures which would likely impact the resulting asphalt’s robustness and resistance to wear.

SEM images of the FNS and IFW. (a) FNS, 0.5 kx, (b) IFW, 0.5 kx, (c) FNS, 5 kx, (d) IFW, 5 kx. Image Credit: Wang, Y et al., Sustainability

Performance analysis was conducted using the VESYS modeling software, allowing the analysis of example pavements laid from the sample mixes over time.

This analysis was primarily concerned with the pavements’ rutting performance – an issue that occurs in flexible pavements whereby higher loads lead to densification of the asphalt and shear deformation.

The study showed promising results, revealing that the use of between 25% and 50% of the natural sand in warm mix asphalt with iron filing waste increased its Marshall stability by between 13.7% and 18.9%.

There was also a notable effect of the warm mix asphalt’s volumetric properties, its air void concentration, and the number of voids found in the mineral aggregate.

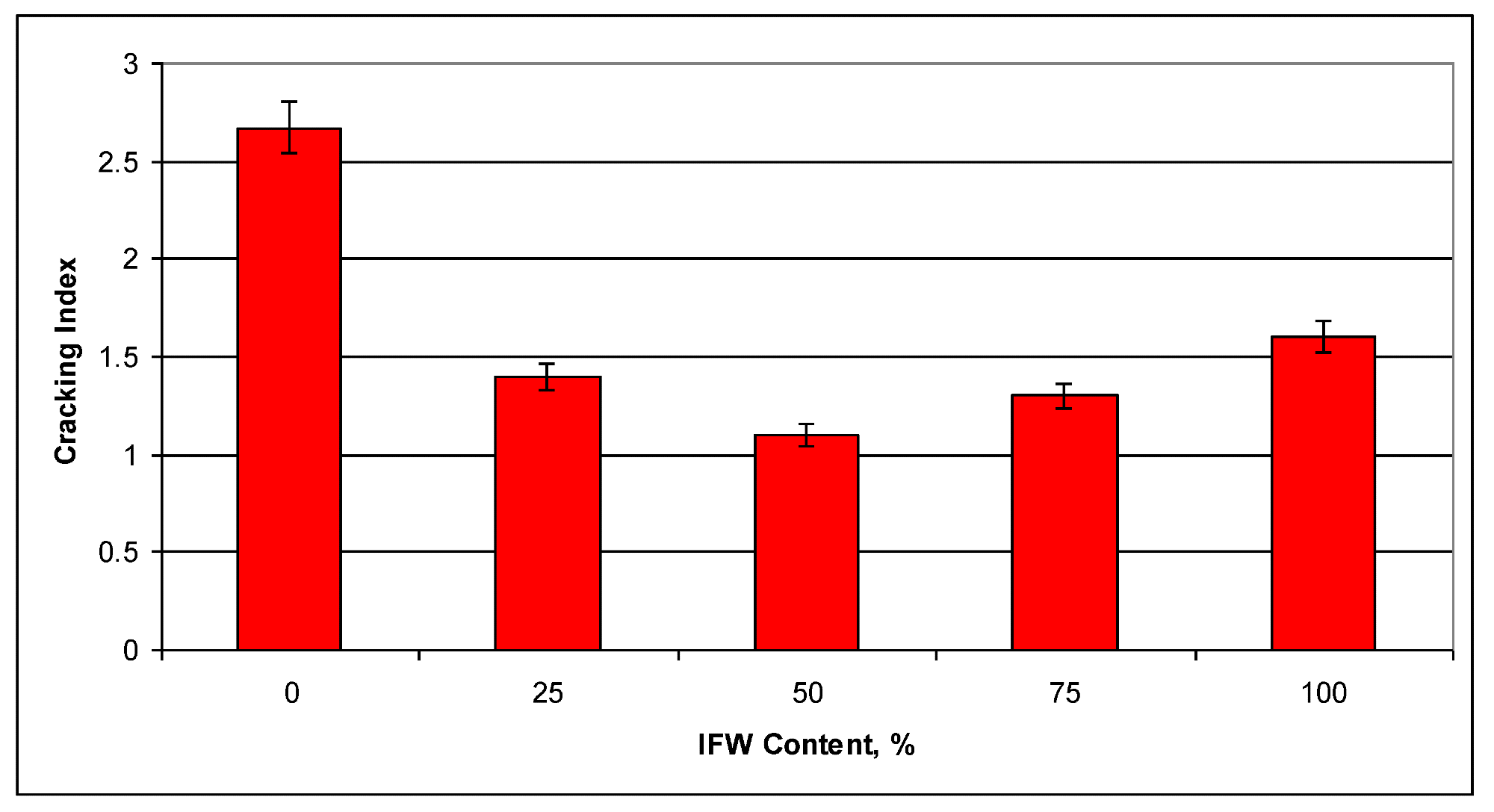

Interestingly, the study determined that the inclusion of iron filing waste led to a significant reduction in fatigue cracking, with the sample containing 50% iron filing waste resulting in a clear improvement in the asphalt’s fatigue resistance under repetitive loading and wet conditions – an ideal consideration for surfaces which are destined to see a heavy foot and vehicle traffic.

In terms of the example pavements’ rutting performance, modeling showed that concrete pavements utilizing iron waste filings demonstrated a lower level of rutting versus the control mix, potentially offering up to 10 years of service life.

Cracking index for the CM and IFW blends. Image Credit: Wang, Y et al., Sustainability

The use of recycled materials in construction applications is set to continue to expand. As more and more materials become viable options for inclusion in construction materials, it will be important to strike a careful balance between ensuring these materials offer the performance and mechanical characteristics required while striving to utilize the most sustainable and environmentally friendly options available.

This study has opened up the possibility of using locally sourced manufacturing waste for such a purpose, demonstrating that not only was this a better alternative than sending this waste to landfills but that the optimized inclusion of iron filing waste could actually enhance the properties of warm mix asphalt.

References

Wang, Yu, Roaa H. Latief, Hasan Al-Mosawe, Hussein K. Mohammad, Amjad Albayati, and Jonathan Haynes. 2021. "Influence of Iron Filing Waste on the Performance of Warm Mix Asphalt" Sustainability 13, no. 24: 13828. https://www.mdpi.com/2071-1050/13/24/13828

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.