In a recent study published in the journal Materials, researchers from Spain analyzed the factors affecting the failure of asphalt pavements due to fatigue cracking of the bituminous layers viz. temperature, rest periods, and aging using a strain sweep test i.e., ensayo de barrido de deformations (EBADE) test.

Study: The Effect of Temperature, Rest Periods and Ageing on the Response of Bituminous Materials in Fatigue Tests: Considerations and Proposals on Analytical Dimensioning Models. Image Credit: Volodymyr_Shtun/Shutterstock.com

The analytical dimensioning models of asphalt pavements assumed that the damaging effects of different traffic loads obey Miner’s law: they are linear and cumulative. Additionally, the aging of the pavement asphalt layers led to stiffening and transverse cracking, which resulted in undersized structures.

Fatigue Failure of Asphalt Pavement

In most analytical dimensioning methods for asphalt pavement, it is assumed that the pavement behaves as a set of superimposed continuous elastic layers.

These fail because of fatigue cracking, and the test further estimates the number of cycles that the pavement can withstand under the stresses produced by the passing loads at the base of the bituminous layer of the pavement. The stresses due to cyclic loading at high frequencies of 10-30 Hz, the elastic modulus of the bituminous mixtures, and Poisson’s ratio are the primary parameters in determining the strain rate over the number of cycles.

In contrast to the LAS test, in which the strain increase process is carried out quickly and continuously, in a strain sweep tension-compression cyclic test i.e. EBADE test, the strain increase is discrete and 5000 cycles are carried out at each strain level. The EBADE test helps investigate the effect of the rest periods and the cause of the failure more effectively than the LAS test.

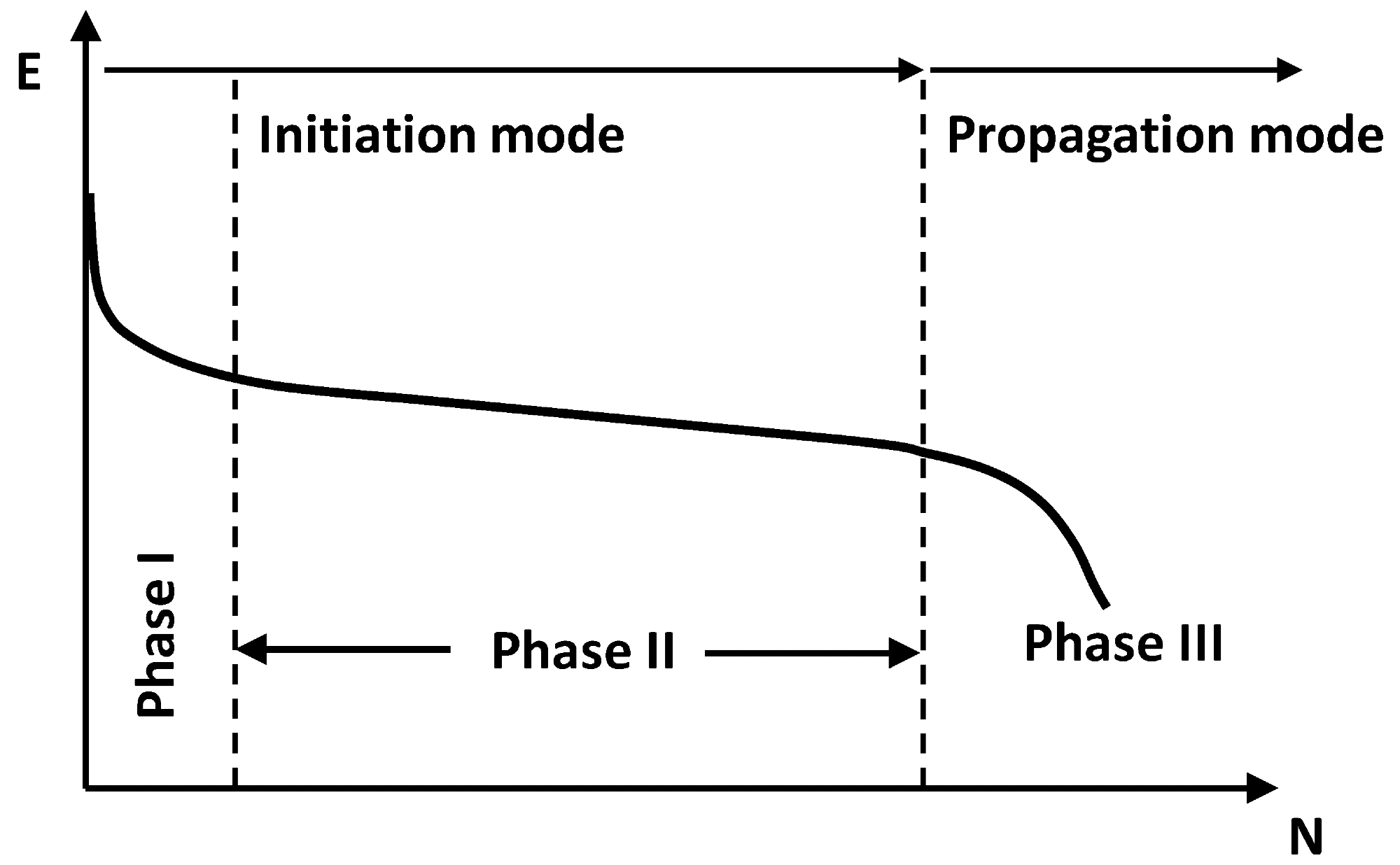

Fatigue graph with the phases. Image Credit: Pérez-Jiménez, F et al., Materials

About the Study

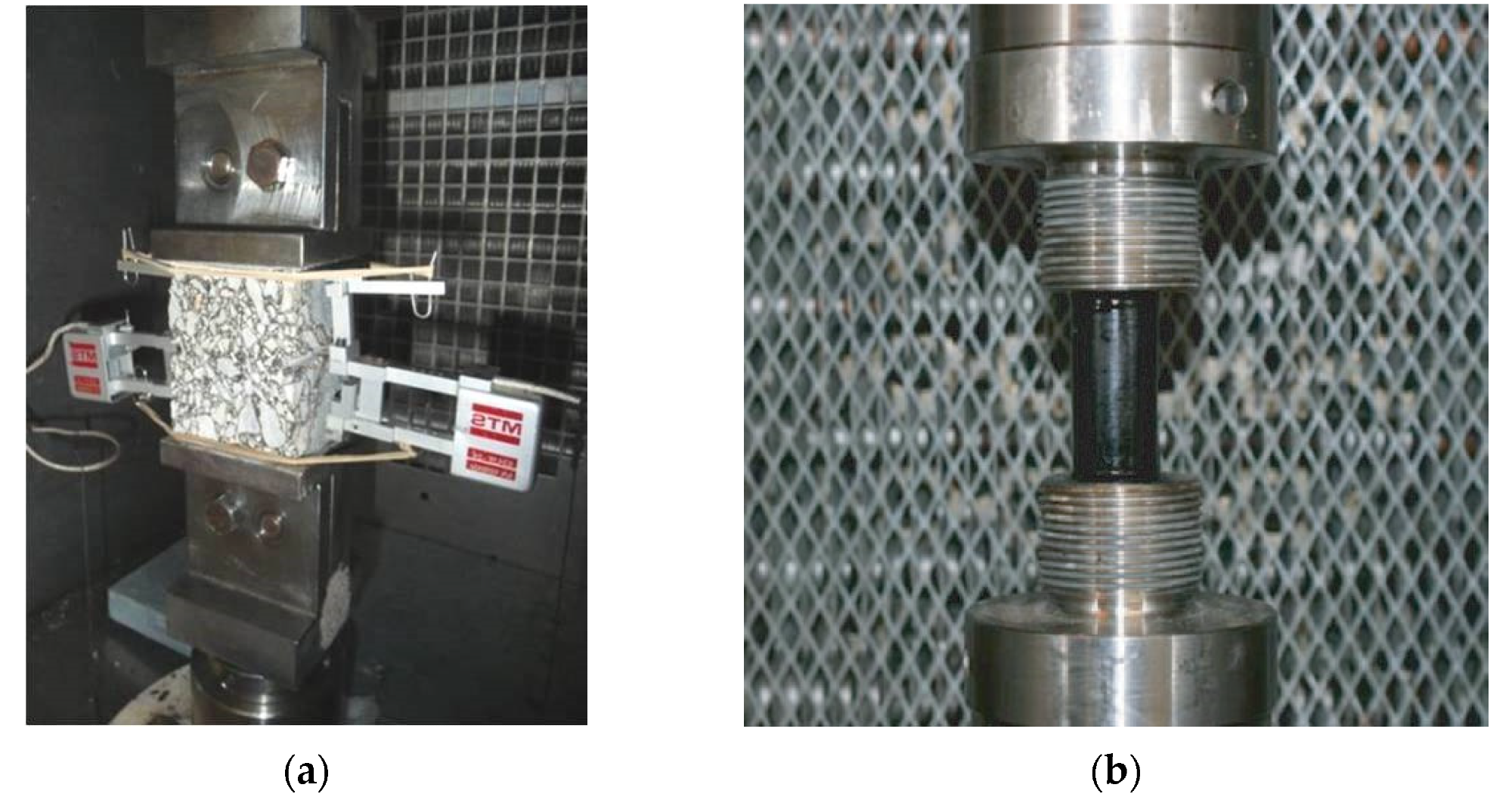

In this study, the researchers used the EBADE test at different temperatures and rest periods. First, the cylindrical specimens were fabricated by pouring hot bitumen and mastics in pure or mixed form into cylindrical molds of 40 mm in height and 20 mm in diameter. The strain was increased by equal quantities every 5000 cycles after an initial strain of 0.076%.

The nature of the damaging effects of different traffic loads was assumed to follow Miner’s law: they are linear and cumulative. Three phases of the samples’ lifespan, namely Phase I, Phase II, and Phase III, were identified based on the relationship between elastic modulus (E) and the number of cycles (N).

Furthermore, to investigate the effect of the temperature, separate samples were subjected to a temperature range of -5 to 20 ℃ at the same strain rate and a fixed cyclic loading frequency of 10 Hz. The failure strain was expressed in terms of the dissipated energy-cycle curves and associated with the load step at which the dissipated energy dropped below 50% of the maximum.

EBADE tests set up for (a) prismatic asphalt mixture and (b) cylindrical asphalt bitumen specimens. Image Credit: Pérez-Jiménez, F et al., Materials

Observations

The results obtained in the EBADE were superimposed on those of the time sweep test for the same strain level. Moreover, the response of the material was mainly dependent upon the strain level rather than the path followed to reach that strain level.

The modulus-phase angle curve showed that the variation of modulus and phase angle with increasing strain was not linear. At certain strain levels in phase II, the maximum no-damage level, bitumen showed recovery of its initial properties when the test was stopped. Also, with an increase in the strain level, the modulus decreased and the phase angle increased significantly.

Furthermore, the sample without any rest period failed before 100,000 cycles, whereas the samples subjected to 10 min rest period every 200 cycles withstood more than 190,000 cycles without any noticeable damage. The response of each sample was ductile and thixotropic at 20 ℃.

(a) Cracks from the top down and (b) Typical alligator skin cracking failure. Image Credit: Pérez-Jiménez, F et al., Materials

Conclusions

In summary, the researchers of this study used a strain sweep tension-compression cyclic test - the EBADE test - to analyze the effect of temperature, rest periods, and aging on the fatigue failure of asphalt pavement comprising of pure bituminous material or their mixtures.

Each sample was subjected to an equal strain step-by-step. Each step consisted of 5000 cycles at a cyclic loading frequency of 10 Hz and in a temperature range of -5 to 20 ℃.

The temperature at which the samples had a ductile and viscous response was associated with a thixotropic model. They exhibited a continuous change of the rheological characteristics depending on the history of the applied stresses. The increased frequency of rest periods significantly increased the cyclic loading of all samples before reaching the failure for any strain level.

Additionally, the brittle response of the mix took place at 10 ℃ higher than that of the original mix. This study provides an effective analytical model to investigate the transverse cracking of asphalt pavements.

Reference

Pérez-Jiménez, F., Miró, R., Botella, R., López-Montero, T., Martínez, A., The Effect of Temperature, Rest Periods and Ageing on the Response of Bituminous Materials in Fatigue Tests: Considerations and Proposals on Analytical Dimensioning Models. Materials, 2022, 15, 790. https://www.mdpi.com/1996-1944/15/3/790

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.