By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 28 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 28 2022In an article recently published in the journal Chemical Engineering Journal, the researchers presented the development of hydrate-phobic surfaces inspired by onions.

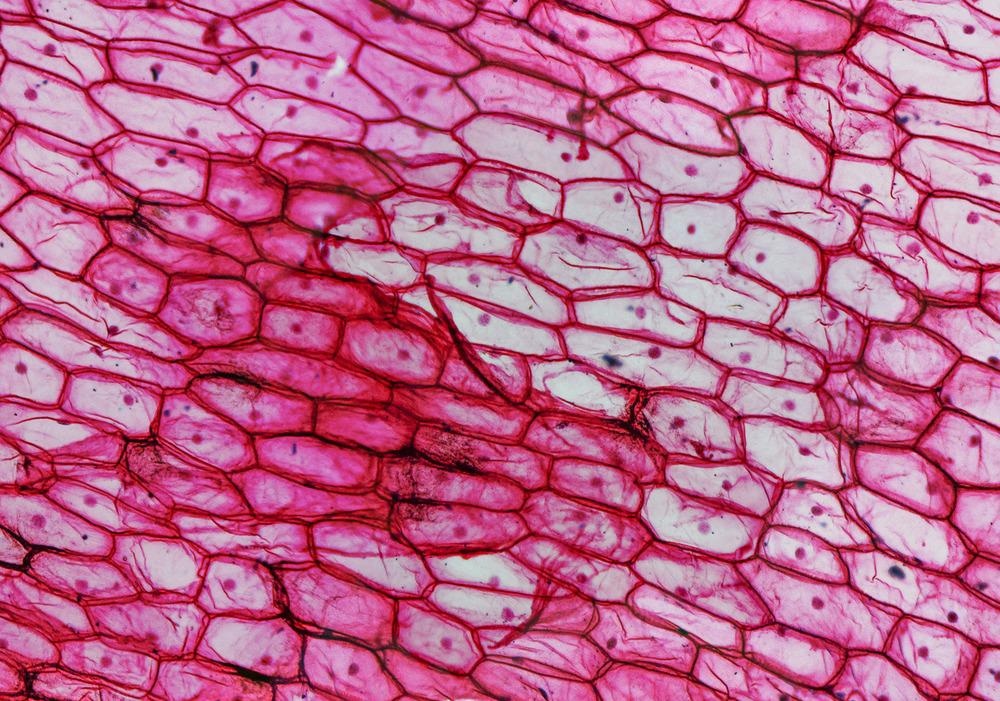

Study: Onion inspired hydrate-phobic surfaces. Image Credit: Claudio Divizia/Shutterstock.com

Background

Natural gas hydrate, a cage-like water skeleton containing imprisoned methane molecules, is a viable future energy resource. Despite the enormous potential of gas hydrates in a variety of applications, undesirable gas hydrate accumulation continues to pose a problem for gas and oil production and transportation networks.

In the industry, state-of-the-art mitigation of hydrate-plugging primarily relies on active approaches such as giving thermal energy to melt hydrates or applying chemicals to prevent hydrate development. These approaches, on the other hand, are energy-intensive, pricey, and may also cause environmental issues.

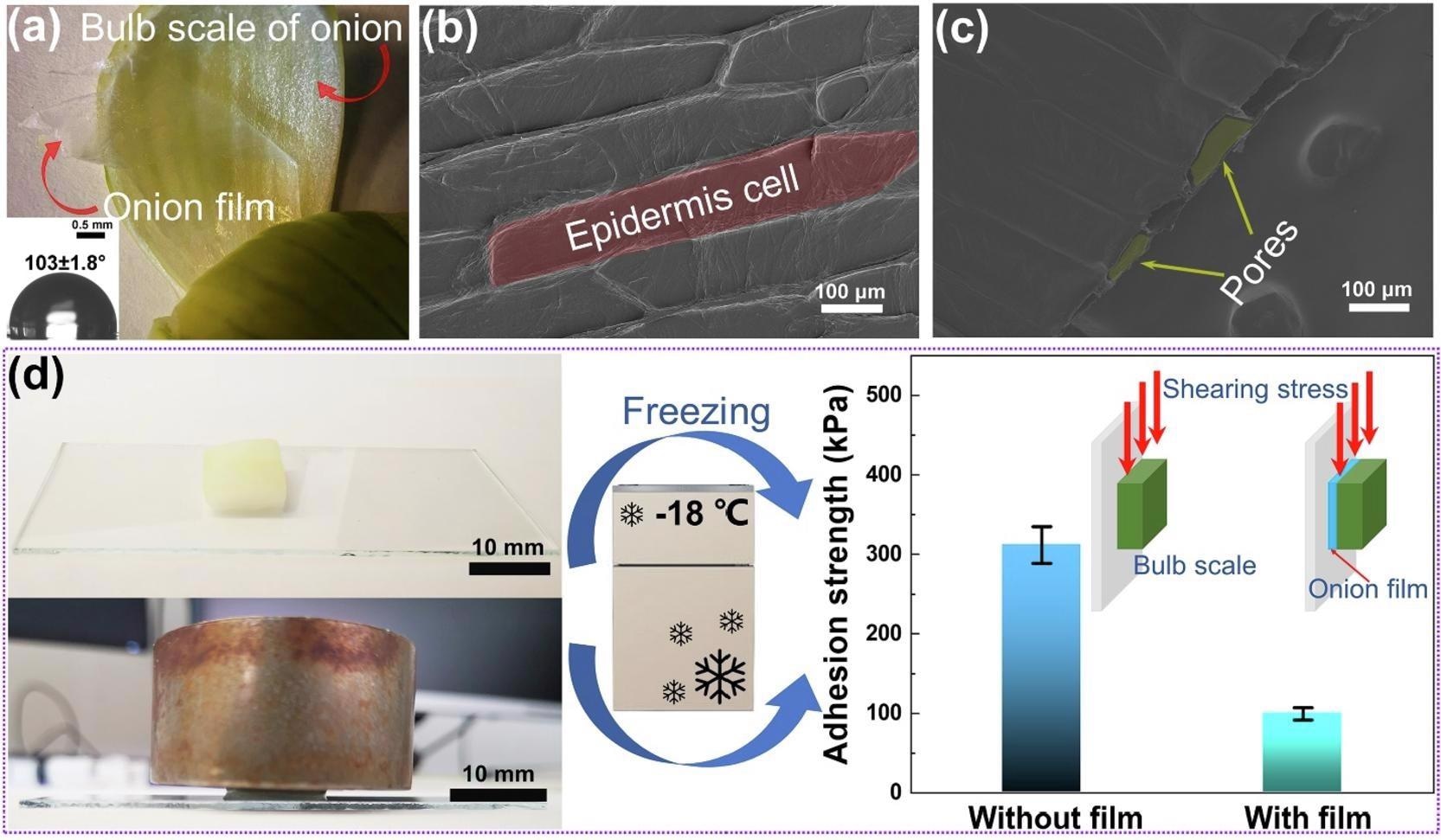

Properties of onion films in lowering adhesion strength. (a) An onion film on a bulb scale of onion. The onion film is an intermediate epidermis between two bulb scales. The water contact angle on the film is shown as inset. (b) The corrugated surface morphology of an onion film. (c) The porous structures of an onion film shown by SEM image. The pores in the monolayer of epidermal cells are highlighted. (d) Samples of onion bulb scales with and without an onion film are cut into small pieces for quantifying their adhesion strength onto glass under −18 ℃ is measured. Image Credit: Wang, F. et al., Chemical Engineering Journal

Anti-hydrate passive surfaces having the ability to remove hydrates on their own are desired. Surprisingly, due to the porous architecture and surface cuticle layer, a thin onion film peeled off from an onion bulb scale has poor hydration adhesion. Anti-gas hydrate surfaces could be created by anti-icing surfaces, according to recent research. Bio-inspired ice phobic surfaces are one of the most appealing anti-icing techniques.

Despite the fact that a variety of surfaces have been created for anti-icing applications, ranging from pitcher-plant inspired slippery liquid-infused porous surfaces to lotus-leaf inspired superhydrophobic surfaces, bio-inspired anti-hydrate surfaces are still in their infancy.

About the Study

In the present study, the authors presented the development of a hydrate-phobic onion-inspired surface with extremely low hydrate adhesion strength by replicating the bio-properties of an actual onion film. Furthermore, by incorporating a regenerable artificial cuticle layer, the efficacy of this new hydrate-phobic surface was improved, allowing for even lower hydrate adherence. The potential applications of onion-inspired surfaces towards alternate hydrate mitigation strategies were also discussed.

The onion film's extraordinary performance in lowering adhesion strength was investigated in this study, and the results were used to fabricate an onion-inspired surface with superior low hydrate adhesion strength. After that, an onion-inspired surface was created to emulate the onion film's low hydration adhesion capabilities, with specific attention paid to the material's endurance.

A novel anti-hydrate surface was devised, and the key properties of onion films used in diminishing onion bulb scale adhesion were incorporated in the as-developed surface for very less hydrate adhesion. The surface fabrication approach for incubation of low hydrate adhesion through sub-surface features and surface lubrication was described in detail. On the onion-inspired surface, the mitigated hydrate adhesion was explored.

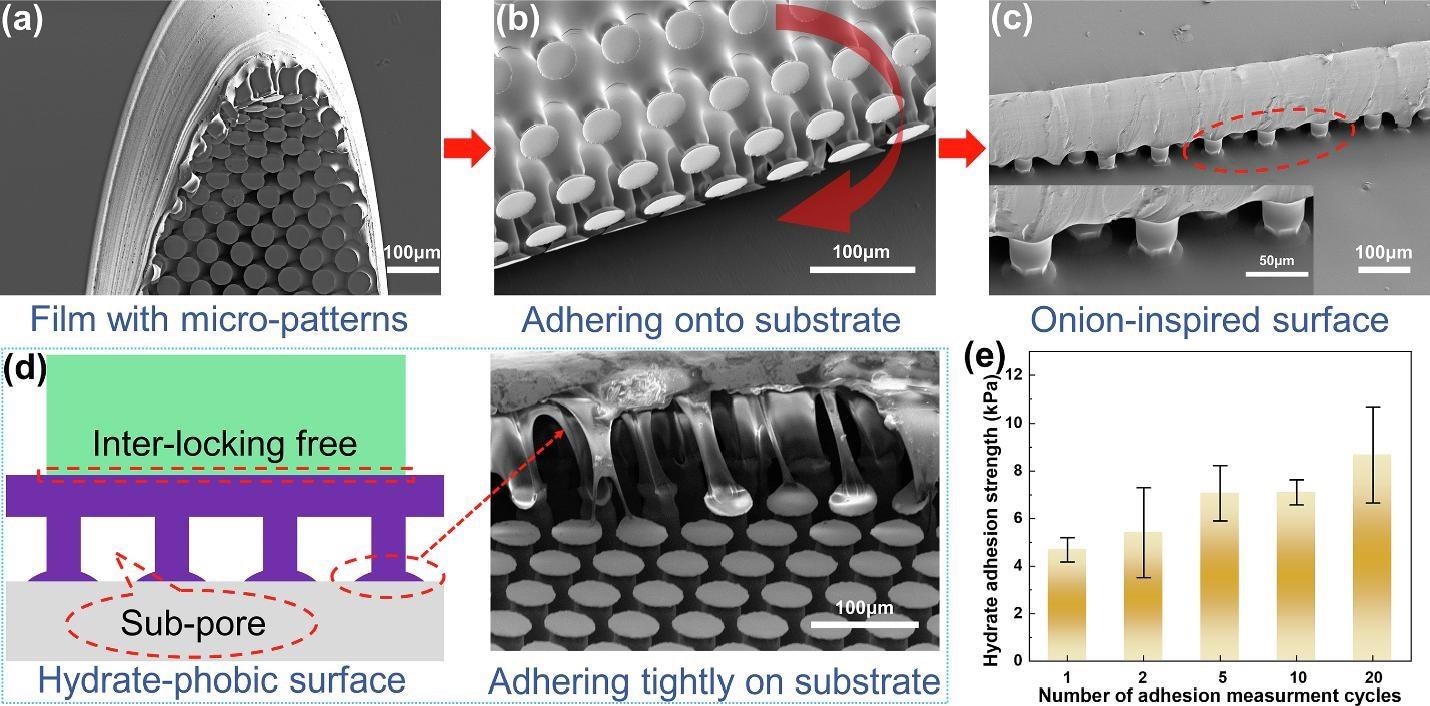

Onion inspired anti-hydrate surfaces. (a) The microscope pillar structures of the gecko tape used as template for create sub-surface pore structures to mimic onion films. (b) The as-prepared film with uniform micro-pillars adhering onto a glass substrate. The interval distance of the pillars is close to the dimension of the pores in onion films. (c) The resulted onion inspired anti-hydrate coating has a smooth top surface and well-organized sub-surface pores. (d) Schematics of the onion inspired hydrate-phobic surface with the advantage of strong adhesion to various solid substrates. (e) The hydrate adhesion strength on the onion inspired coating in cyclic de-hydrate test. The hydrate adhesion strength is measured under −18 ℃ with CyC5 hydrate. Image Credit: Wang, F. et al., Chemical Engineering Journal

Observations

In this study, the researchers observed that the onion-inspired surface reduced the cyclopentane (CyC5) hydrate adhesion strength from 95 kPa to 4.7 kPa by creating numerous pores beneath the smooth surface. After 20 hydrating/dehydrating cycles, the onion-inspired surface still had a very low hydrate adhesion (8.7 kPa). The hydrate adherence of the proposed hydrate-phobic surface was determined as 2.9 kPa.

Furthermore, it was observed that even at a low temperature of 18°C, the onion film retained its elasticity. On onion film coatings, the CyC5 hydrate adhesion strength dropped dramatically from 95 kPa on raw glass to 16 kPa. The hydrate adhesion strength on the onion-inspired surface was found to be exceedingly low, with a mean value of roughly 4.7 kPa and a reduction of more than 95% when compared to that of pure glass.

The new coating's hydrate adhesion strength remained extremely low, with an average value of 8.7 kPa after 20 dehydrating/hydrating cycles. After 20 dehydrating/hydrating cycles, the onion-inspired surface maintained good hydrate-phobicity with a low hydrate adhesion strength of 8.7 kPa.

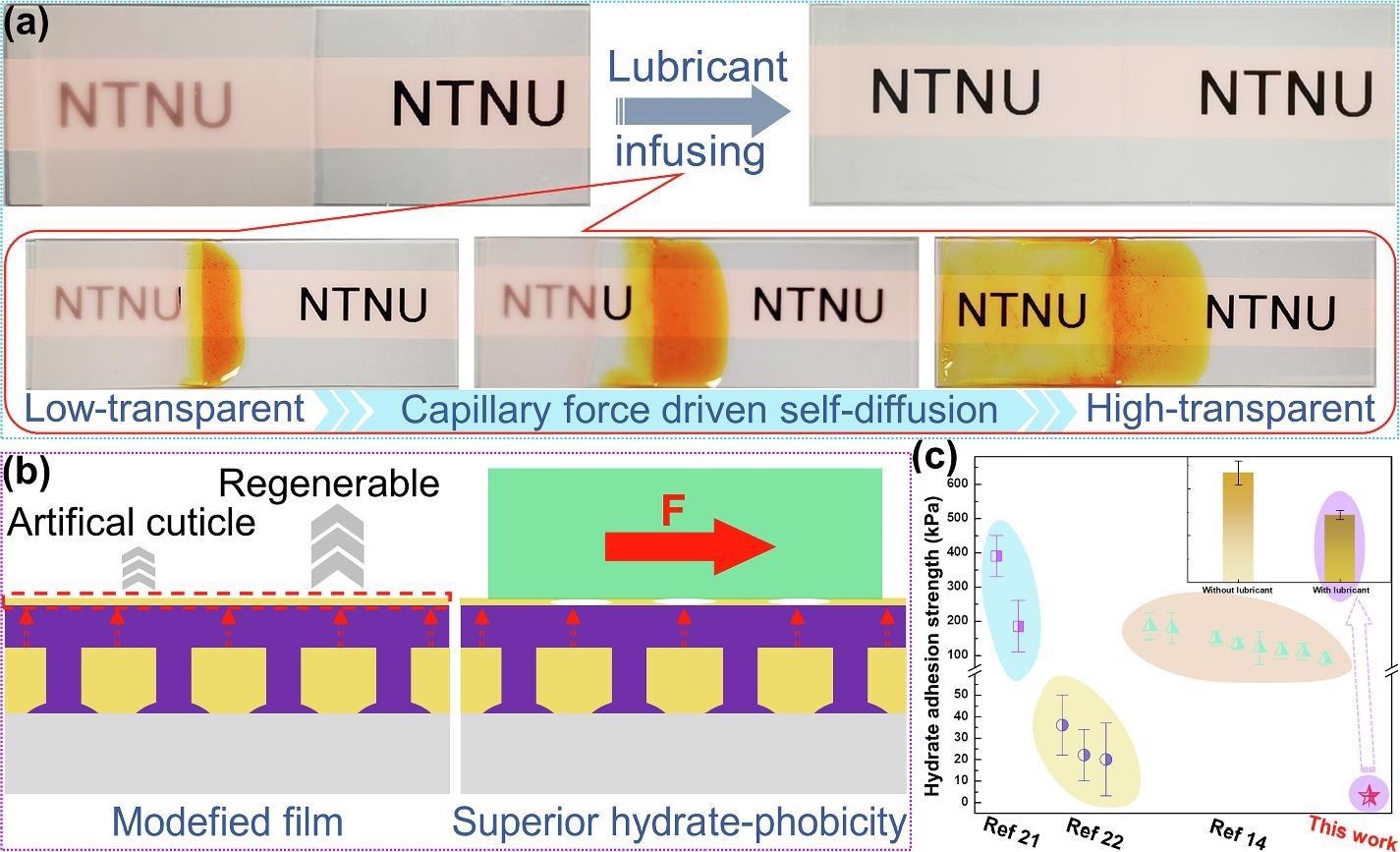

Cuticle mimicking layer on the onion inspired coating with superior hydrate-phobicity. (a) High transparency of the coating with infused lubricant in the sub-surface pores. The detailed self-diffusion process of lubricant infusing driven by capillary force is shown by dyed silicone oil. (b) Schematics of the regenerability of the lubricant layer and the resulting superior hydrate-phobicity. (c) The comparison chart that shows the hydrate adhesion strength in the literatures and in this work. The hydrate adhesion strength on the onion inspired surfaces with and without artificial cuticles are inserted. The hydrate adhesion strength is measured under −18 ℃ with CyC5 hydrate. Image Credit: Wang, F. et al., Chemical Engineering Journal

Conclusions

In conclusion, this study elucidated that the hydrate-phobicity of the surface created with this regenerable slippery lubricating layer is exceptional, indicating that it has significant potential for practical anti-hydrate applications. It was observed that the novel onion-inspired coating achieves an extraordinarily low hydrate adhesion strength of 2.9 kPa by generating a flat surface with sub-surface pores on a strong elastomer.

It was also determined that the low hydrate adhesion is attributed to the sub-surface pores and the above cuticle layer. This work demonstrated that the cuticle can operate as a hydrophobic lubricating layer for further decreasing hydrate adhesion, while the sub-surface porous structures can produce stiffness inhomogeneity and initiate interface fissures. The authors believe that this study's in-depth bio-inspiring technique also paves the way for the development of new anti-hydrate materials.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Wang, F., Xiao, S., He, J., et al. Onion inspired hydrate-phobic surfaces. Chemical Engineering Journal 437(1) 135274 (2022). https://www.sciencedirect.com/science/article/pii/S1385894722007781