A team of researchers from the Arctic University of Norway’s Faculty of Engineering Science and Technology in Narvik has investigated various modification strategies to improve the performance of anodes for use in microbial fuel cells. The study has been published online in the journal Energies this week.

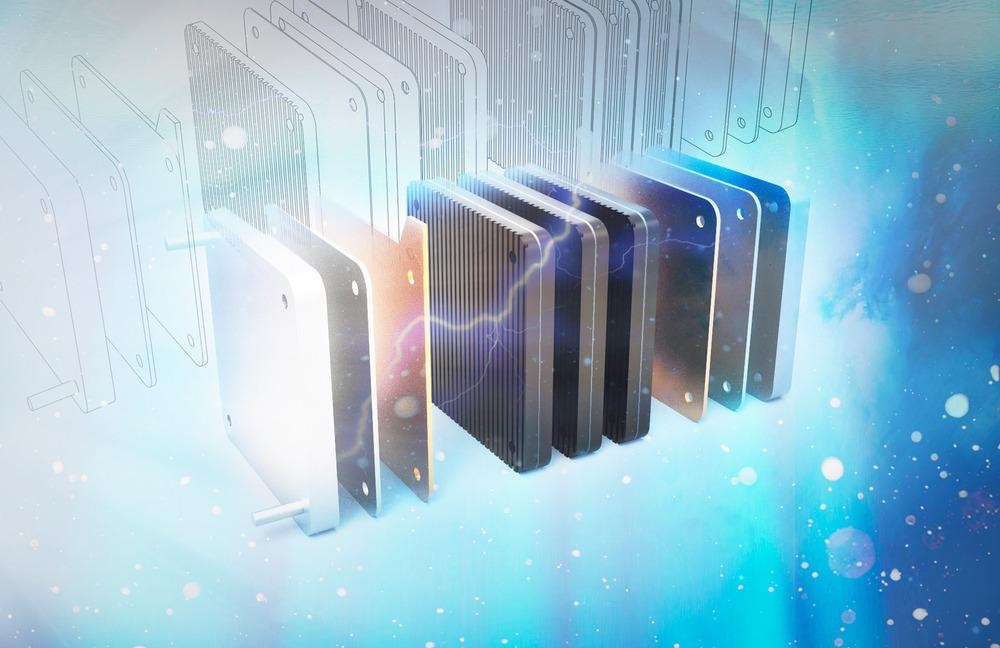

Study: Review on Material and Design of Anode for Microbial Fuel Cell. Image Credit: Polina Krasnikova/Shutterstock.com

Microbial Fuel Cells

Microbial fuel cells are a next-generation energy generation solution that has been the focus of intense research in recent years. These devices generate electricity by anaerobically oxidizing substrates. Whilst the devices themselves are a relatively recent development in the field of next-generation energy research, the roots of the technology can be found in the discovery of bioelectricity in the late 18th century by Luigi and Lucia Galvani.

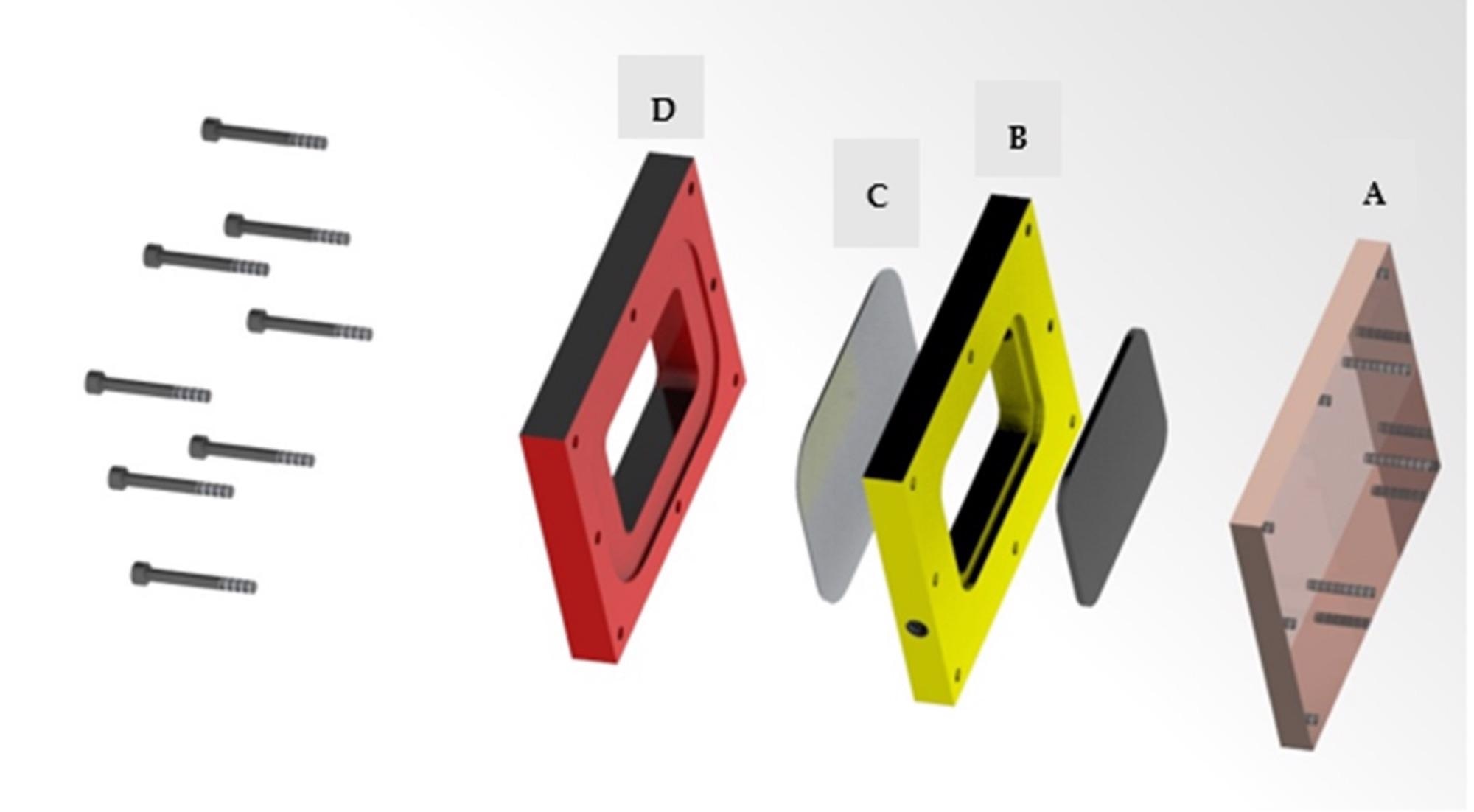

Schematic configuration of a Microbial Fuel Cell (A: End Plate; B: Anode Chamber; C: Membrane; D: Cathode Chamber). Image Credit: Banerjee, A et al., Energies

Several technologies have been developed in recent years based on the principle of bioelectric generation aside from microbial fuel cells. Microbial fuel cells have attracted attention for the treatment of wastewater and the recovery of energy through direct electricity generation.

Microbial fuel cells only require wastewater as fuel. The conversion of fuel to electricity is facilitated by bacterial metabolism. In these devices, the design plays a crucial role in achieving optimal performance, and key components in the technology such as electrodes and membranes are selected based on their cost and properties. Microbial fuel cells are self-sufficient.

The structure of a microbial fuel cell consists of two electrodes separated by a proton exchange membrane. Several materials have been explored for the membrane, including Nafion, which is the most common material used for this purpose. Studies have investigated incorporating materials such as tungsten oxide, and research has concentrated on improving crucial properties such as fouling resistance, chemical degradation, species crossover, and mechanical degradation.

Proper selection of microbial species plays a key role in microbial fuel cell design as they metabolize the organic material and produce protons and electrodes in the anode chamber of the device. Electrons are then transferred to the cathode chamber through an external circuit, which generates electricity. Microbial activity depends on the wastewater’s characteristics such as concentration, pH, dissolved solids, and so forth. Moreover, the characteristics of the organic substrate influence the kinetics of the biochemical reaction in the fuel cell’s anodic chamber.

However, microbial fuel cells have not been widely adopted thus far. Research has concentrated on improving the performance of key components in order to make the technology economically viable and use it as an alternative water treatment solution.

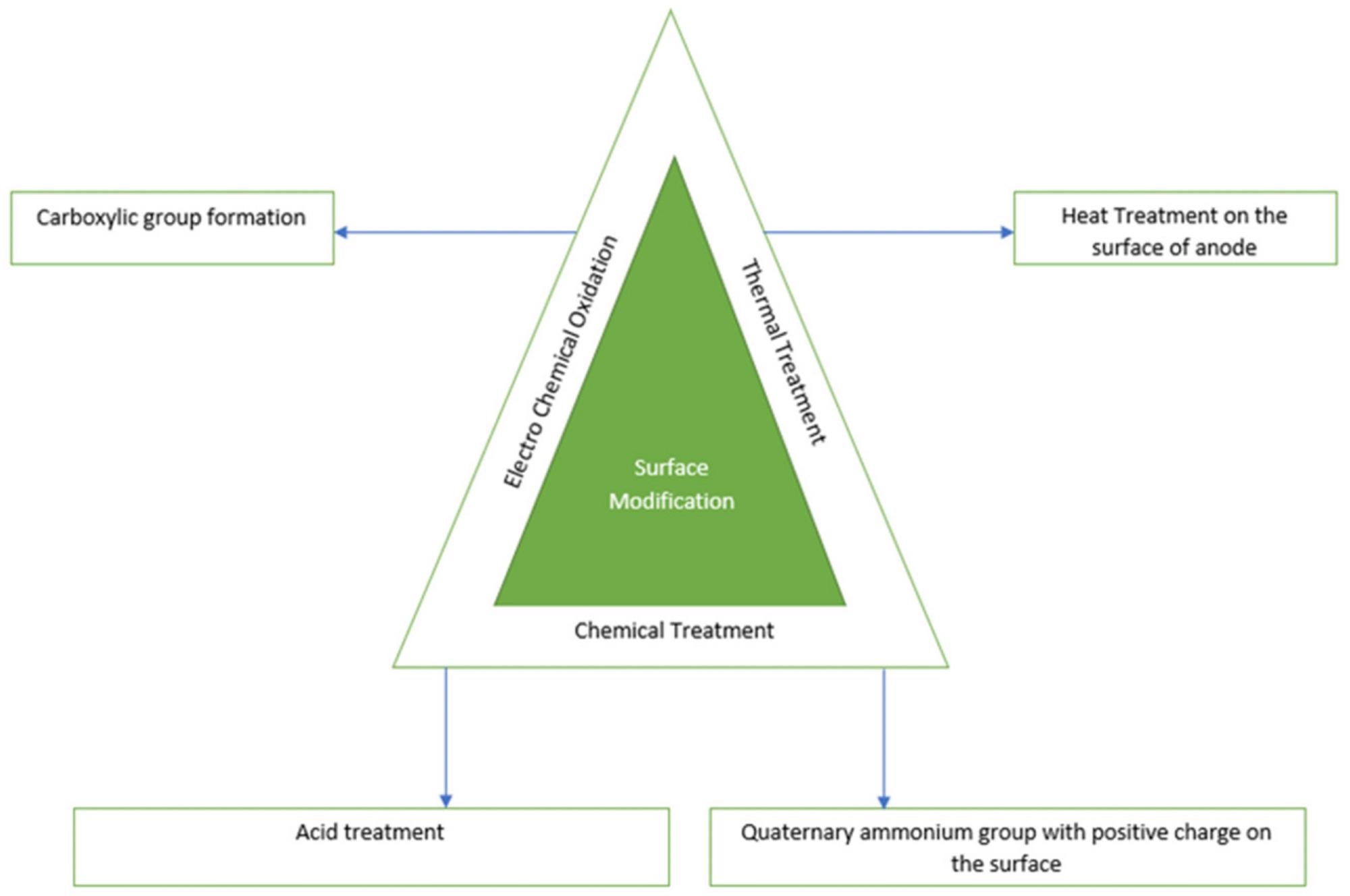

Classification of surface-modified anode based on the physicochemical treatment. Image Credit: Banerjee, A et al., Energies

The Study

The paper presented in Energies has considered the key characteristics of anodes in microbial fuel cells and reviewed the various materials that have been proposed for them. The impact of materials on both performance and cost have been evaluated by the authors, and additionally, the design strategy for selecting the most appropriate materials has been described in depth in the review with the aim of improving the overall performance of microbial fuel cells.

Several materials have been used for anodes in microbial fuel cells in research studies. An essential property is conductivity, with metals such as platinum, copper, and stainless steel widely explored. However, they may not be suitable for microbial activity. Metals such as platinum and titanium display advantageous properties but are expensive.

![Schematic diagram of (a) synthesis and (b) formation of CuCO2S4/rGO [70].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58627_16481208433201184.jpg)

Schematic diagram of (a) synthesis and (b) formation of CuCO2S4/rGO. Image Credit: Banerjee, A et al., Energies

The anaerobic conditions in the anodic chamber enhance the microbial growth on the anode’s surface. Techniques to tailor anodic materials to favor biofilm adhesion on the anode’s surface include acid treatment and polymer coatings. Anodes must possess chemical compatibility, durability, porosity, electrical conductivity, and a large surface area, which influences the selection of appropriate materials. Additionally, biocompatibility is vital for the design of anodes in microbial fuel cells.

Carbon-based anodes have been investigated in recent research, including materials such as graphene. Much research has been carried out into optimizing carbon nanomaterials for use as anodic materials. Additionally, natural waste materials have been investigated as carbon sources, and whilst raw waste materials need to be processed, they are advantageous in terms of cost, availability, biocompatibility, and stability.

Surface treatments, doping, copolymer hybridization, and coatings have been widely investigated to improve the properties of anodic materials, especially those derived from biomass, to improve electrical conductivity and other properties.

Finally, the authors have presented some future perspectives on research into anodic materials for microbial fuel cells. One perspective highlighted in the review is the binding of graphene oxides derived from organic waste with Nafion or PES. This can be used as a coating for metal composite brush materials, forming an efficient microbial fuel cell electrode that satisfies several requirements. Further analysis of the combined effect will be necessary in future research.

Further Reading

Banerjee, A, Calay, R.K & Mustafa, M (2022) Review on Material and Design of Anode for Microbial Fuel Cell [online] Energies 15(6) 2283 | mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/6/2283

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.