By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 30 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 30 2022In an article recently published in the open-access journal Materials, researchers investigated the electrochemical energy storage characteristics of high-porosity foamed cement.

Study: Electrochemical Energy Storage Properties of High-Porosity Foamed Cement. Image Credit: Stock Kryvyi Rih/Shutterstock.com

Background

Building energy consumption accounts for a considerable share of overall societal consumption of energy, and this proportion is likely to grow as people's expectations for quality of living continue to rise. As a result, building energy efficiency is seen as a critical component of achieving carbon emission reduction goals.

Energy supply and storage equipment are required for building energy-saving devices and management systems. Batteries and supercapacitors are examples of structural energy storage technologies that solely store electrical energy and require external packaging to maintain mechanical integrity.

Carbon fiber (CF) and all electrodes attached to a solid polymer electrolyte (SPE) matrix are the key components of currently developed multifunctional structural supercapacitors (MSS). Because of their low thermal conductivity and superior seismic performance, cement-based foamed materials with enhanced porosity have been widely used in civil infrastructure for shock absorption barriers and thermal insulation.

The majority of current studies on porous cement-based materials focus on the effects of the water-cement ratio, foaming agent, and other parameters on thermal resistance and porosity. The electrochemical energy storage performance of porous cement materials, on the other hand, has received little attention.

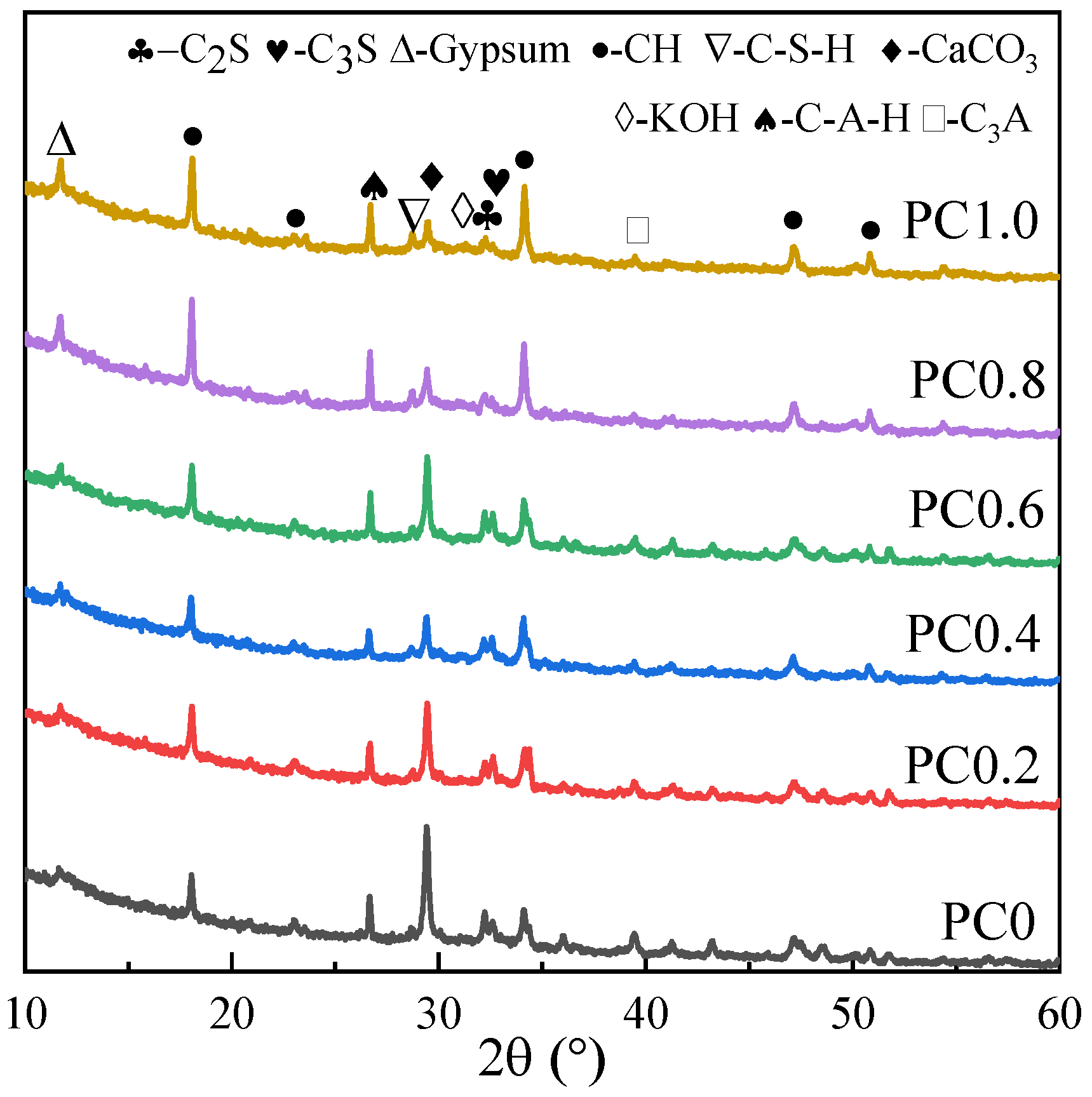

XRD patterns of various cement specimens. Image Credit: Zhou, C et al., Materials

About the Study

In this study, the authors used H2O2 used as a foaming agent in the production of foamed porous cement products. The impact of H2O2 dose on multifunctional performance was investigated. The performance of electrochemical energy storage was evaluated in unique methods. Regular Portland cement was used as the cementitious material and H2O2 as the foaming agent to create a high-porosity foamed cement. The impact of H2O2 mass content on the foam cement's electrochemical performance and multifunctionality was demonstrated in-depth.

The researchers presented the development of specimens of cement pastes with various mix designs. Graphene oxide (GO) suspension was coated on the foam of nickel (Ni) and cured for 2 hours at 60 °C. The GO/Ni foam was placed in a hydrothermal reaction tank with 60 mL of deionized water and kept at 180 °C for 12 hours.

A field emission scanning electron microscope was used to examine the micromorphology of the prepared foamed cement samples. The chemical components were studied using powder X-ray diffraction. The porosity of samples was determined using mercury intrusion porosimetry.

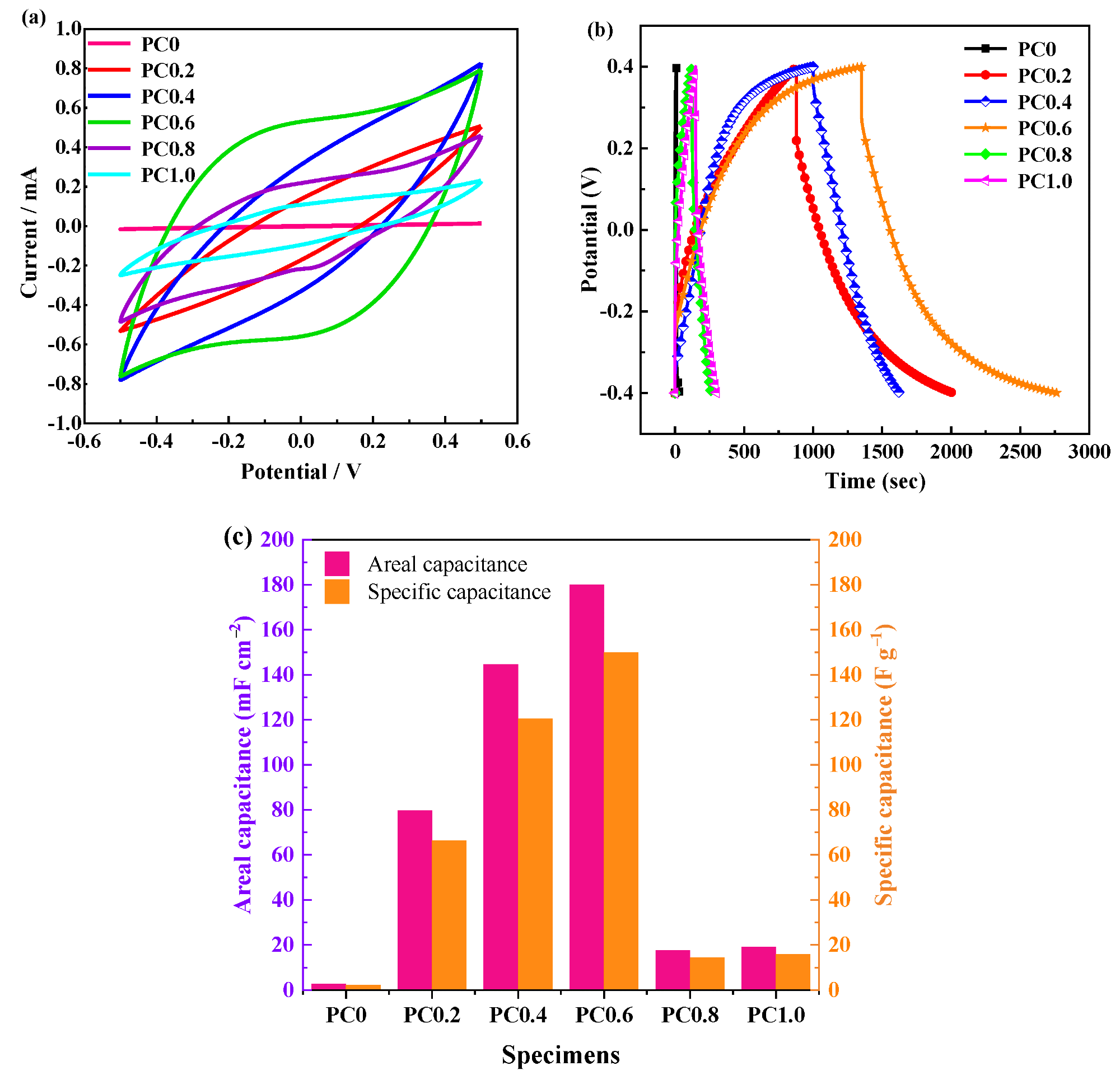

The team used two-electrode cells on a CHI660E electrochemical work station to evaluate the electrochemical characteristics of the produced cement pastes and build energy storing devices. At a potential range of 0.5 V, galvanostatic charge/discharge (GCD) tests and cyclic voltammetry (CV) was performed. The cement pastes were analyzed using electrochemical impedance spectroscopy (EIS) in the frequency range of 0.01 Hz to 105 Hz.

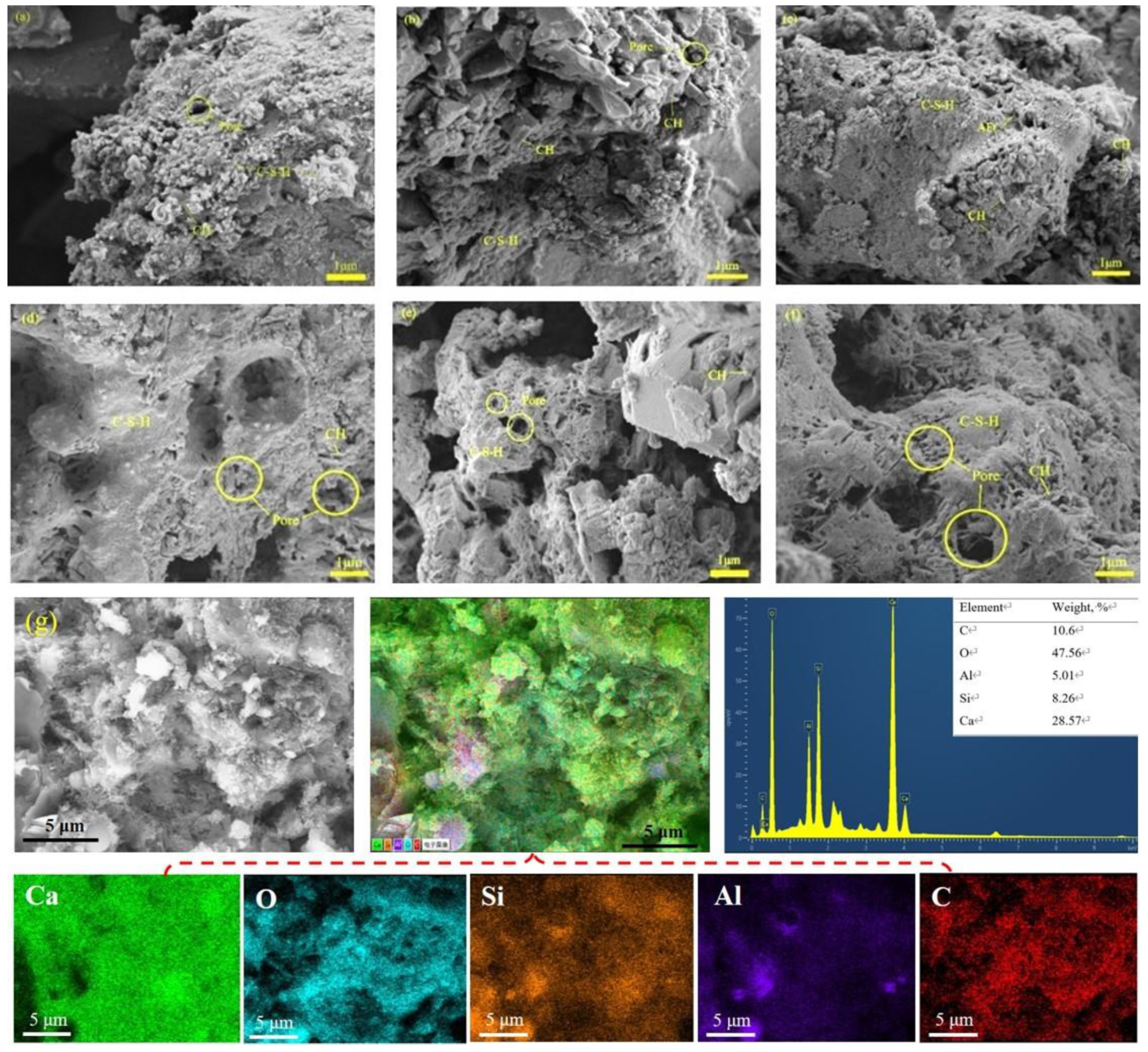

SEM images of various cement specimens, (a) PC0; (b) PC0.2; (c) PC0.4; (d) PC0.6; (e) PC0.8; (f) PC1.0; and (g) EDS elemental mapping of PC0.6. Image Credit: Zhou, C et al., Materials

Observations

Hydration gels, hydration products (CH), holes, and a few microcracks made up the microstructure of specimens. Pure cement slurry had an ionic conductivity of 21.41 mS cm-1. Because of the increased pore number, the ionic conductivity increased from 12.52% to 39.28% after adding the foaming agent H2O2. Furthermore, PC0.6 had the maximum ionic conductivity value of 29.82 mS cm-1. Pure cement had a compressive strength of 22.8 MPa.

The developed specimen with 0.6% H2O2 of regular Portland cement mass (PC0.6) exhibited enough porosity, which resulted in exceptional multifunctional properties. The corresponding compressive strength was 19.6 MPa, and the ionic conductivity was 29.07 mS cm-1. At a current density of 0.1 mA cm-2, the PC0.6 had the largest areal capacitance of 178.28 mF cm-2.

The PC0.6 solid electrolyte had the highest areal capacitance of 179.98 mF cm-2 and the highest specific capacitance of 150.0 F g-1. The discharge time reduced as the current density increased from 0.1 to 0.5 mA cm-2. At 0.1, 0.2, 0.3, and 0.5 mA cm-2, the areal capacitances were 178.28, 60.52, 52.06, and 40.28 mF cm-2, respectively. As the charge/discharge current density increased from 0.1 to 0.5 mA cm-2, the specific device capacitance with PC0.6 decreased from 148.57 F g-1 to 33.56 F g-1.

After 2000 cycles at 0.1 mA cm-2, the arial capacitance and coulombic efficiency of the device with PC0.6 remained at 90.67% of initial capacitance and 94.58%. The compressive strength of the sample decreased after the H2O2 was added. Its compressive strength ranged from 17.7 to 18.7 MPa when the H2O2 level was between 0.4 and 1.0%. The compressive strength increased to a high of 19.6 MPa when the H2O2 level was around 0.4%.

(a) CV curves; (b) GCD curves; and (c) the corresponding areal capacitances and specific capacitance of devices based on different cement pastes. Image Credit: Zhou, C et al., Materials

Conclusions

In conclusion, this study elucidated the development of high porosity foamed cement materials by modifying the foaming ingredient H2O2. The effects of adding H2O2 to the foamed cement material on its structure, shape, and electrochemical energy storage ability were investigated.

The authors emphasized that the high-porosity foamed cement has increased contact area with the electrode, and the porous structure affords a large number of ion transport channels, which may explain the good electrochemical performance.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Zhou, C., Wang, Q., Zhang, C., Electrochemical Energy Storage Properties of High-Porosity Foamed Cement. Materials 15(7) 2459 (2022). https://www.mdpi.com/1996-1944/15/7/2459