By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 11 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 11 2022In a review recently published in the open-access journal Energies, researchers discussed new research trends regarding proton exchange membrane fuel cells.

Study: Novel Trends in Proton Exchange Membrane Fuel Cells. Image Credit: PixelSquid3d/Shutterstock.com

Background

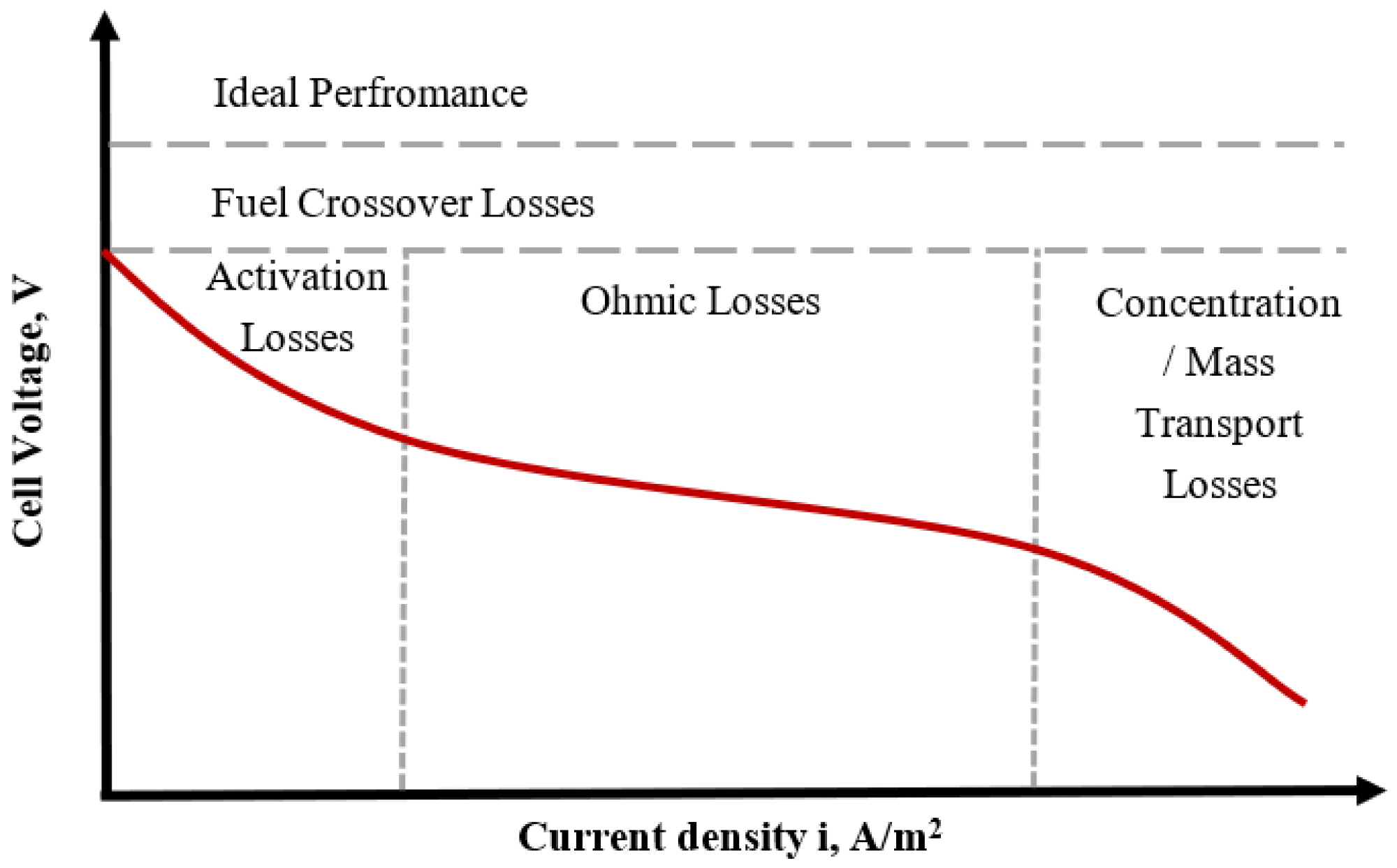

A fundamental prerequisite for the effective utilization of renewable energy sources is the development of eco-friendly and efficient energy conversion technologies. Fuel cells (FCs) are electrochemical systems that have shown promising results when used with various renewable energy sources. Since hydrogen has no adverse effects on the environment and can be created from water using electrolysis and other techniques, it is thought to be the fuel of the future. The most typical type of FC predicted to have the greatest impact on the energy generation sector is the low-temperature proton exchange membrane fuel cell (PEMFC).

Despite the fact that PEMFCs have several benefits, their commercialization is constrained by competition from traditional combustion engines. In the most recent few decades, the creation of inexpensive yet long-lasting FCs has advanced more quickly. Before PEMFCs can successfully replace conventional power systems, they must first address a number of problems. The potential for adoption of this technology is mostly influenced by the price per kW of the FC system and the availability of hydrogen supply. New supply routes for hydrogen have been given in a number of studies; however, the price is still high. Additionally, in order to make this market lucrative and accessible to more users, the producers must lower manufacturing costs and, as a result, the price per kW.

Polarization curve with the electric losses’ regions encountered with the operation of PEMFC (adapted from [28] (license no. 5172430728078)). Image Credit: Olabi, A. G et al., Energies

About the Study

In this study, the authors looked into the many parts of proton exchange membrane fuel cells (PEMFCs) and how they were made. The difficulties faced by these manufacturing methods were examined thoroughly, and some solutions were suggested.

The team presented a thorough analysis to understand the current state of fuel cell operational characteristics and identified new areas for development in the young and evolving PEMFC technology. The theory covered in this study was intended to help fuel cell development in some way.

The researchers investigated and critically examined the present and cutting-edge materials utilized for PEMFCs, as well as their characteristics and the numerous fabrication processes used to make FC components.

![Schematic diagram of membrane electrode assembly [37] (open access).](https://www.azom.com/images/news/ImageForNews_59526_16575288351409007.png)

Schematic diagram of membrane electrode assembly [37] (open access). Image Credit: Olabi, A. G et al., Energies

Observations

The liquid elastomer could cure in 15 seconds and reached a thickness of 0.4 inches. According to the findings, an SS304 sheet wrinkled and was broken at very different speeds, with greater formability at speeds between 0.1 and 1.1 m/s. When compared to sputtering, electron beam reduction electrodes were more efficient, with optimal power densities of 0.56 W/cm2 for the former and 0.36 W/cm2 for the latter.

Contact resistance between gas diffusion layers (GDLs) and bipolar plates (BPs) could result in the loss of up to 59% of the power in PEMFCs. Metals corroded at faster rates than gold, which had a rate of less than 15 m/year and was comparable to graphite. Metals corroded at rates of roughly 250 and less than 100 m/year for aluminum and stainless steel, respectively.

The Nafion membrane provided the best performance in terms of materials for the catalyst layer and membrane, but it was still expensive. The performance suffered, and the cost increased as a result of attempts to lower the Nafion and platinum concentration. The current focus was on finding new materials that could entirely replace both platinum and Nafion. Corrosion was a significant issue for the BPs, and this is being addressed with coatings. The performance of attempts to create alternative materials to replace metals was not yet equivalent. As a result, attempts were made to create brand-new coating processes that were more effective.

The deflection was the main issue with end plates, especially for stacks with a lot of cells. This issue could be solved by choosing a material having high tensile strength but low weight.

![(a,b) Schematic of PEMFC showing the bolts and nuts; (c) diagram for what happens to the MEA when subjected to clamping pressure; (d) diagram for a unit cell; (e) clamping pressure and strain; (f) relationship between clamping pressure and contact resistance [134] (license no. 5175230250109).](https://www.azom.com/images/news/ImageForNews_59526_16575288542059809.png)

(a,b) Schematic of PEMFC showing the bolts and nuts; (c) diagram for what happens to the MEA when subjected to clamping pressure; (d) diagram for a unit cell; (e) clamping pressure and strain; (f) relationship between clamping pressure and contact resistance [134] (license no. 5175230250109). Image Credit: Olabi, A. G et al., Energies

Conclusions

In conclusion, this study examined the materials and production of the various PEMFCs. A lot of attention was paid to the unique PEMFC materials and their qualities, and fabrication techniques for making PEMFC components were also investigated.

The membrane electrode assembly was one of the components reviewed. The authors mentioned that the PEMFCs have advanced, but there are still issues with cost and durability that must be resolved before they can be implemented widely. Low power density and mechanical durability are issues for the FC.

They also stated that despite all the advancements in research and optimization made over the past few decades, the PEMFC is a unique energy-converting technology, and thus there is still opportunities for development.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Olabi, A. G., Wilberforce, T., Alanazi, A., et al. Novel Trends in Proton Exchange Membrane Fuel Cells. Energies 15(14) 4949 (2022). https://www.mdpi.com/1996-1073/15/14/4949