In a paper recently published in the open-access journal Materials, researchers investigated the thermo-electrical properties of polyamide (PA)/carbon black (CB) nanocomposites. The team demonstrated methods to appropriately improve the self-heating of the conductive polymer composites (CPCs) while reducing their percolation threshold.

Study: Enhanced PTC Effect in Polyamide/Carbon Black Composites. Image Credit: Eaum M/Shutterstock.com

Background

Engineering applications such as aircraft and automobiles have shown potential for the use of self-heating nanocomposites that have a positive temperature coefficient (PTC). The combination of various polymers with electrical, conductive, chemical, or mechanical properties can be tuned and tailored to provide a response to external stimuli such as humidity, strain, temperature, or damage.

Such CPCs can be incorporated in different kinds of fillers such as graphite, metal, CB, or carbon nanotubes. Thus, the three-dimensional (3D) state of the filler network inside the polymer, as well as the electrical characteristics, can be controlled by the dispersion state, aspect ratio, and the filler amount.

PTC is the increase in the electrical resistivity shown by certain composites sensitive to temperature. Several theories attribute the impact of PTC primarily to the amount of filler-to-filler contacts and the material’s inconsistent thermal expansion. The polymer matrix’s thermal expansion separates the embedded electrically conductive filler particles. This disruption in the filler connectivity increases the electrical resistance. However, in a molten state, the higher mobility of the filler elements allows them to form additional filler paths, thereby decreasing the electrical resistance.

The abovementioned properties, therefore, make CPCs suitable for sensor-based applications such as self-regulating heaters with a broad range of applications like thermo-clothing and automotive interior heating systems. The present study highlights the correlation between the properties of PTC-heaters and polymer crystallinity, as well as the CB’s specific surface area that is incorporated to facilitate the manufacture of high self-heating nanocomposites having enhanced PTC behaviors.

![Schematic representation of the electrically conductive filler network within the non-conductive polymer [17,18].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59744_16600371503237193.png)

Schematic representation of the electrically conductive filler network within the non-conductive polymer. Image Credit: Nagel, J., et al., Materials

About the Study

In this study, the team used two types of PA - PA 4.6 and PA 6.10 - with crystallinities of 60-70% and 30-40%, respectively, and three kinds of CB, CBI, CBII, and CBIII with specific surface areas of 70 m2/g, 770 m2/g, and 1,000 m2/g, respectively. An epoxy with silver filling was used for the electrical contact of the samples. Four composite samples were produced through melt compounding containing 25 wt%, 20 wt%, 15 wt%, and 10 wt% of CB.

The samples were injection molded while retaining constant holding pressures and the dosage volumes for the PAs. The specific surface area of CB was measured by a Belsop-mini X followed by the investigation of the composite microstructures. Furthermore, the crystallinity degree and the thermal characterization of the PAs and their composites were carried out using a differential scanning calorimeter, while the coefficient of thermal expansion (CTE) was assessed using a dilatometer. Thereafter, the samples were analyzed for their self-heating characteristics under a 24V applied voltage for four minutes and the variations in the surface temperatures and electrical resistance were recorded with a multimeter and a thermography camera.

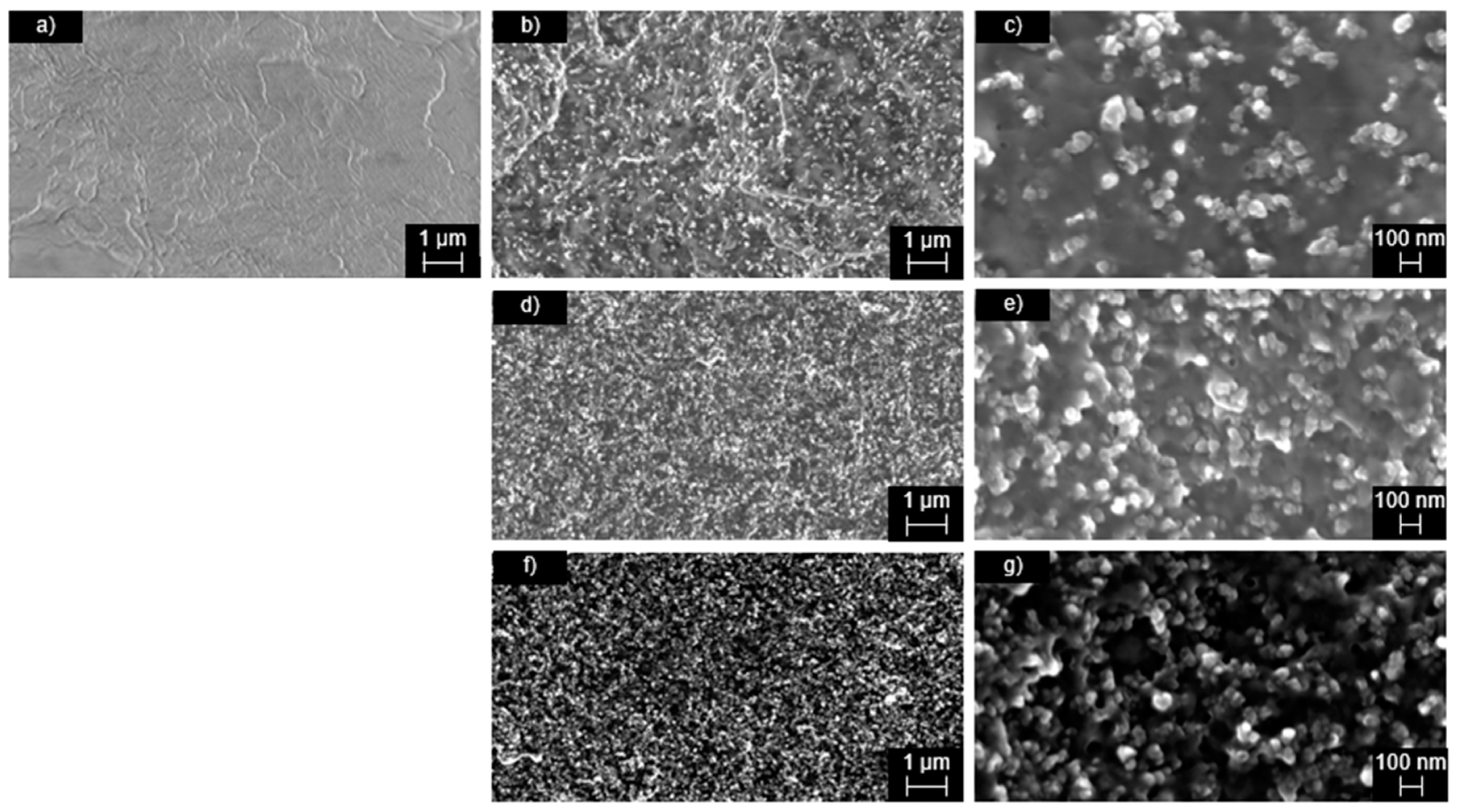

SEM images of neat PA 6.10 (a), 20 wt.% CB I (b,c), 20 wt.% CB II (d,e) and 20 wt.% CB III (f,g). (a,b,d,f) are shown with a magnification of 10.0 k, while (c,e,g) shown with a magnification of 50.0 k. Image Credit: Nagel, J., et al., Materials

Observations

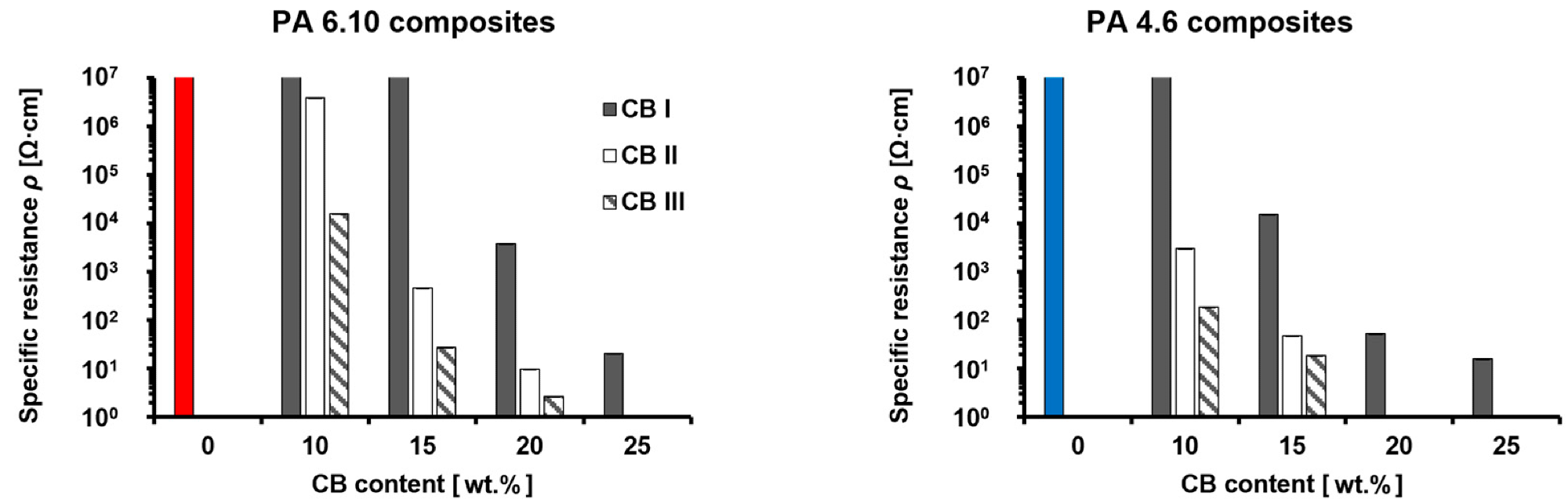

It was observed that the composites with low specific surface areas contained fewer CB particle connections, while those with larger specific surface areas exhibited continuous filler networks and decreased free volume among the particles. On the other hand, the increase in polymer crystallinity and the specific surface area and content of CB decreased the samples’ specific resistance. Higher CB content favors the chances of contact between CB particles and the subsequent formation of additional conductive paths.

Moreover, composites with lower crystalline PA 6.10 exhibited greater resistance compared to those with high crystalline PA 4.6. The increased crystallinity reduces the free volume in the amorphous phase containing the fillers and therefore enhances the particle contacts.

It was further observed that lower CB content and higher specific surface area achieved improved self-heating performance. With regards to PTC, PA 4.6 and PA 6.10 exhibited comparable CTE at around 80°C. The PTC-Effect was significant for CBI at around 110°C, whereas no distinct PT-Effect occurred on the PA 4.6 composite. Additionally, during the self-heating experiments, the PTC-Effect was reversed. The highest PTC-Effect was shown by the CBI composite, while the PA 4.6 composites exhibited a substantial jump in the specific resistance with temperatures ranging from -24°C to 150°C. This behavior was not exhibited by the PA 6.1 composites.

Shows the average specific resistance ρ of five specimens. PA 6.10/CB (left columns) and PA 4.6/CB (right columns) where neat PA 6.10 and neat PA 4.6 are represented by red and blue colors, respectively. The values of neat PA 6.10 and PA 4.6 are 6.5·1012 Ω·cm and 1015 Ω·cm, respectively. Image Credit: Nagel, J., et al., Materials

Conclusions

To summarize, the researchers determined that a highly crystalline polymer with a lesser CB-specific surface area can be used to achieve adequately low room-temperature specific resistance along with high self-heating properties. They further established that adjusting PTC behavior and heating performances of self-heating nanocomposites resulted in several efficient heating solutions. According to the authors, self-heating composites show considerable PTC-effects of about 53% at average temperatures of 147°C, which indicates the promising performance of nanocomposites as heating devices.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Nagel, J., et al. (2022) Enhanced PTC Effect in Polyamide/Carbon Black Composites. Materials, 15, 5400. https://doi.org/10.3390/ma15155400