Conventional robots, such as those employed in manufacturing, are capable of lifting heavy objects and precisely performing automated procedures. Yet, they are too stiff and heavy for delicate work and human interaction. The study of soft robotics focuses on creating robots with flexible technical parts and soft, organic materials.

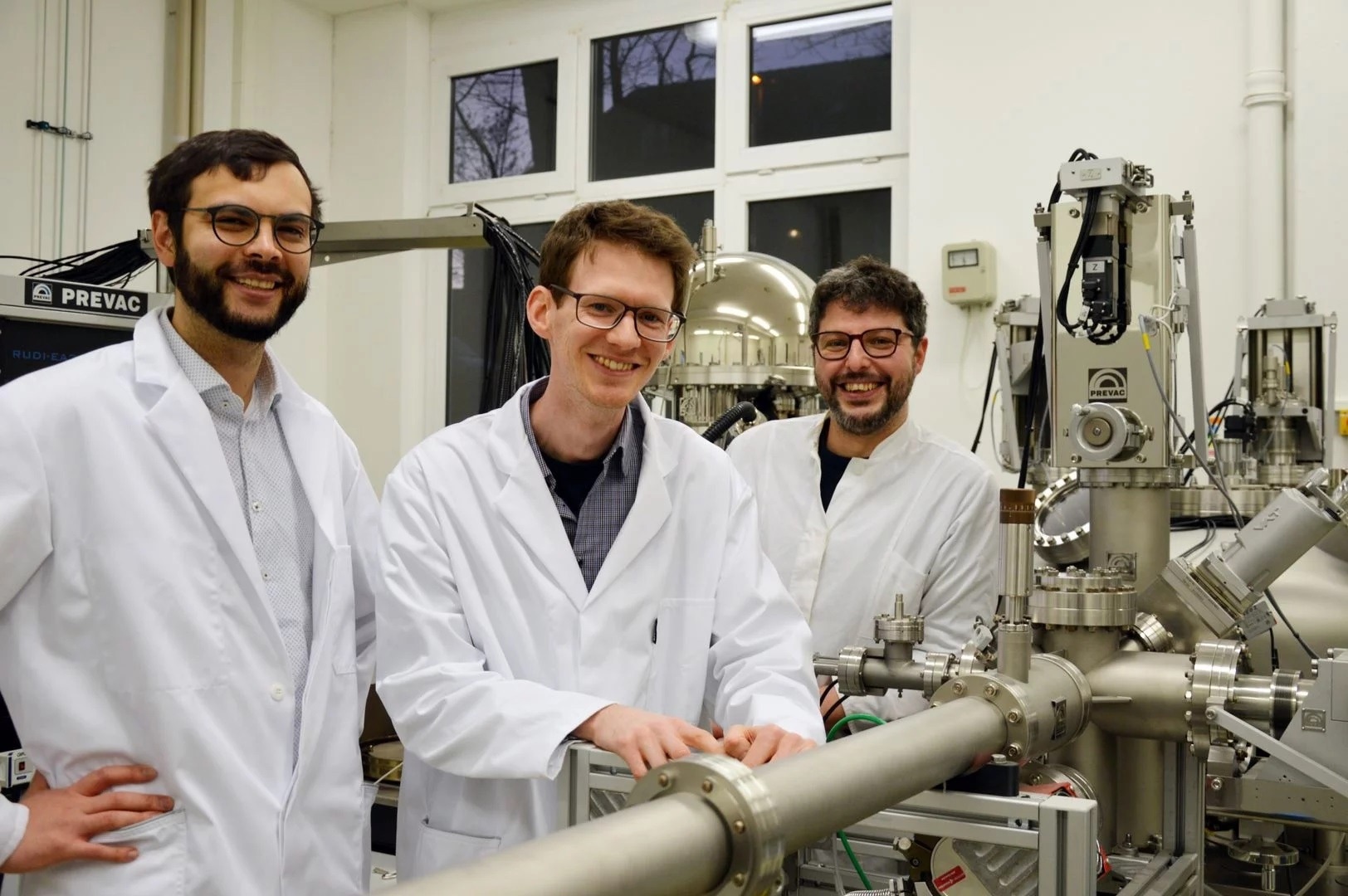

Doctoral researcher Igor Barg (from left) and junior research group leaders Stefan Schröder and Fabian Schütt developed the material for the elastic conductor. Image Credit: Julia Siekmann, Uni Kiel

Doctoral researcher Igor Barg (from left) and junior research group leaders Stefan Schröder and Fabian Schütt developed the material for the elastic conductor. Image Credit: Julia Siekmann, Uni Kiel

A unique soft conductive material has recently been created by material scientists at Kiel University; results were published in Advanced Functional Materials.

It has exceptionally stable electrical characteristics even when deformed, unlike ordinary soft conductors. This is caused by the material’s unique structure and a thin, insulating layer made of nanoscale particles.

Constant Electrical Resistance, Even During Deformation

Humans and animals are capable of performing fluid and precise motions and adapting them to their surroundings, unlike classical robots. Soft robotics, which takes its cues from nature, uses carbon-based elastic, organic materials rather than conventional, rigid metals. Moreover, “soft” robots require elastic electrical conductors to connect their actuators and sensors.

Conventional conductors made of metal conduct electricity well, of course, but they are too rigid for flexible components. Upon deformation they change their electrical resistance and this affects their use in soft robotics.

Dr Fabian Schütt, Head, Multiscale Materials Engineering, Chair, Functional Nanomaterials, Kiel University

The material, which Schütt and colleagues at the Institute of Materials Science at Kiel University developed, keeps its resistance even when it is distorted.

The material, which Schütt and colleagues at the Institute of Materials Science at Kiel University developed, keeps its resistance even when it is distorted.

Igor Barg, Study First Author, Doctoral Researcher, Chair, Multicomponent Materials, Kiel University

Researchers from Kiel University’s Priority Research Area KiNSIS (Kiel Nano, Surface and Interface Science) combined their many areas of expertise to produce a material formed of small wires that resembles a black sponge.

Microtubes constructed of an electrically conductive polymer are joined to form the wires. Due to its fine network structure, the material is both very light and elastic.

Nanoscopic Insulation Film Protects the Electrical Properties of the Material

Barg added, “Stretchable, sponge-like conductors have already been researched for several years. But as soon as they are deformed, their resistance also changes due to the so-called piezoresistive effect.”

The researchers covered its material with a non-conductive, nanoscopic thin coating of polytetrafluorethylene (PTFE) to prevent this effect.

“You can think of it as a classic power cable,” Barg further added.

During compression, the layer prevents the wires from coming into direct touch with one another and forming fresh electrically conductive routes. Consequently, even with significant deformations, the resistance does not change. Moreover, the insulation improves the wires’ mechanical stability and shields their electrical properties from outside effects like moisture.

Its highly porous framework construction requires a unique coating method. The Chair for Multicomponent Materials’ Functional CVD Polymers junior research group is led by Dr. Stefan Schröder, who also works with the initiated chemical vapor deposition (iCVD).

This allows for the conformal coating of materials with complicated structures and surfaces: A chemical reaction is triggered by mixing several gases in a reactor, and the material to be coated starts to develop a thin polymer coating.

Since this coating is only a few nanometers thin, the wires remain elastic and the total weight of the material hardly increases.

Dr. Stefan Schröder, Head, Functional CVD Polymers, Chair for Multicomponent Materials, Kiel University

Applications in Medical Technology are Also Conceivable

Schütt added, “This example shows very well how we can use nanoscale coating to specifically change the properties of our framework structures, which are up to several cubic centimeters in size, and even create completely new functions.”

Schröder stated, “By combining our methods, other applications, including commercial ones, might be possible in the future, for example in medical technology or energy storage.”

They currently aim to explore these possibilities in other collaborative research initiatives.

Strain-invariant, Highly Water Stable All-organic Soft Conductors - Compression test

The video of a compression test shows how the coating of the scaffold structure significantly improves the elastic properties. © Igor Barg

Journal Reference:

Barg, I., et al. (2023) Strain-Invariant, Highly Water Stable All-Organic Soft Conductors Based on Ultralight Multi-Layered Foam-Like Framework Structures. Advanced Functional Materials. doi:10.1002/adfm.202212688.