Aug 25 2007

Anode stub toe-in is a known and understood phenomenon in all pre-bake aluminium smelters. The high temperature in the reduction cell causes both the carbon anode and the steel yoke to expand. Carbon expands much less than steel when heated. Because the lower parts of the stubs are cast into the anode block, they are not able to move with the yoke as it expands, and so the stubs bend inwards.

Stubs become bent inwards roughly halfway up their length such that the design geometry of the yoke and stub assembly is no longer maintained, with the result that stubs can no longer be fitted into the holes of the anode block.

In the past, many smelters persisted with toed-in stubs until they were no longer usable, then cut off the bent stub and welded on a replacement. Today, many smelters accept that stub straightening has a demonstrable cost benefit; straight stubs reduce operational difficulties and improve the stub-carbon volt drop.

Stimir of Iceland offers solutions appropriate to various reduction technologies. For smaller diamter stubs, cold straightening is an economical approach – Stimir delivered such a system to Alcan Iceland in May 2004 and a second to Alcan Steg, Switzerland in November 2004. Both machines are for 125mm diameter stubs and straighten the stubs at ambient temperatures.

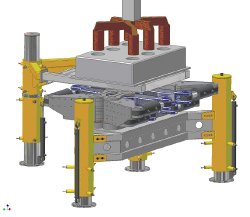

For larger diameters hot straightening is often a better solution. Stubs heated to 650°C need 30% less straightening force, and the cost of an induction pre-heating unit is usually off-set by savings in heavy duty steelwork and hydraulic systems. Stimir has delivered such a stub straightener for 180mm AP-30 stub to Mozambique Alumaium (Mozal) and which was commissioned in September 2005.

Stub Straightener with Induction Heating for AP-30 stubs.

Stub Straightener with Induction Heating for AP-30 stubs.

Stimir hf. is a solution provider to the primary aluminium industry, with particular focus on the Rodding Plant. All aspects of design and fabrication are undertaken at Stimir’s own facilities, ensuring total quality control and on-time delivery.