Over the past couple of years, Mastersizer 3000 particle sizing system has become synonymous in research and development and QA or QC applications. However, customers are planning to switch from the Mastersizer 2000 to the new Mastersizer 3000 system (Figure 1). This article highlights the capabilities of the Mastersizer 3000 system and shows users how to transfer methods from the Mastersizer 2000 to the new Mastersizer 3000 system.

Figure 1. Mastersizer 2000 and Mastersizer 3000.

Compact Design of the Mastersizer 3000

Laser diffraction is being widely used in many quality control applications. Since this method is being applied in standard laboratories, bench space becomes a critical factor. When compared to the Mastersizer 2000, the Mastersizer 3000 has a compact design. The dispersers are also small and lightweight, which make it easy to place the system in the fume hood and provide more space for other equipment.

Measurement Size Range Required

The majority of diffraction systems employ multiple light sources or multiple wavelengths of light. The Mastersizer 3000 features a compact detector that helps in determining a particle size of up to 3.5 mm, although the size of the optical bench is shorter than that of the Mastersizer 2000. In addition, red and blue light sources are introduced to the sample on the same path. This feature together with increased blue light power provides improved sensitivity in the range of 10 to 1000 nm size.

Sample Amount Required for Measurement

Different dispersers are needed for different applications. Certain materials can be suitably determined through dry dispersion process, using the Scirocco 2000 or the Aero S dispersers, while other materials may need to be determined through wet dispersion process, using Malvern Panalytical’s Hydro series of dispersion units.

In applications where wet sample dispersion is required, the Hydro LV dispersion unit has a 600 ml sample tank that is capable of dispersing large-sized samples of polydisperse materials. In the case of smaller volumes of samples, the Hydro MV dispersion unit serves as a substitute for the Hydro 2000S. This reduces the need for costly samples and organic dispersants. All Mastersizer 3000 liquid sample handling units are compatible with chemicals, making it easy to use an extensive range of dispersants.

User-Friendly Software

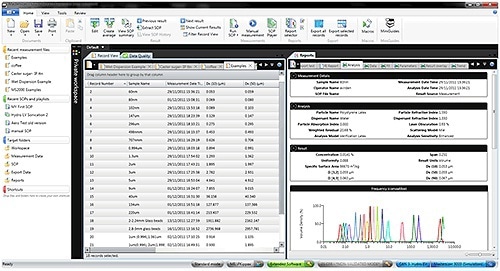

The Mastersizer 2000 system is known for its ease of use and software flexibility. The Mastersizer 3000 software (Figure 2) includes all the features of the Mastersizer 2000, including report views, records view, data export and SOP capabilities. For instance, sorting and filtering of measurement records has been enhanced, which enables users to locate data with respect to different types of products, reports can be designed in-place, and measurements can be compared between different measurement files sans the need for making numerous copies of records.

Figure 2. Mastersizer 3000 software.

Technique of Method Development

The measurement interface in the Mastersizer 3000 offers rapid feedback about the measurement process. Users can leverage the new measurement manager to navigate each step of the measurement process. Unlike the Mastersizer 2000, the Mastersizer 3000 system provides a live result trend view that displays the existing result, data relating to light scattering, and a trend plot demonstrating how the particle size of the sample has altered during the measurement sequence. These features enable users to evaluate the stability of their measurements. In addition, automatic statistics calculations allow users to check whether measurement repeatability is within satisfactory limits.

Measuring Data Quality

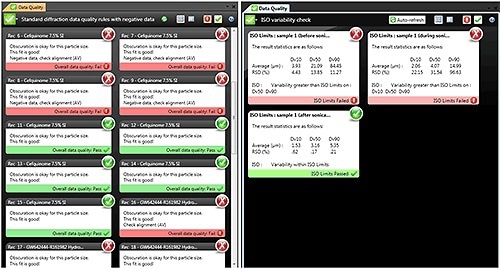

Malvern Panalytical offers excellent training and support to customers. The Mastersizer 3000 Data Quality tool (Figure 3) helps users to optimize their measurements and thus ensures the quality of the measurements made. When this is completed, Malvern Panalytical experts check for data inconsistency and confirm whether results thus obtained satisfy the reproducibility criteria specified in USP<429> and ISO13320:2009 standards.

Figure 3. Mastersizer 3000 Data Quality tool.

Configuration of Analysis Settings

The Mastersizer 2000 system uses the Mie scattering model to determine the particle size distributions of samples having fine particles. This aspect helps in reporting precise results across the system’s measurement range. Nevertheless, when using Mie theory, users have to specify the absorption (imaginary refractive index) and refractive index of samples being tested however, this is a challenging prospect, particularly when new materials are being measured.

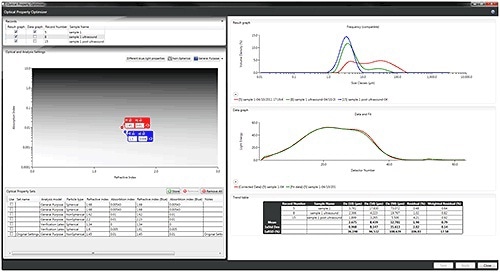

Figure 4. Optical Property Optimizer.

Similar to the Mastersizer 2000, the Mastersizer 2000 uses the same analytical method, enabling users to leverage its measurement capabilities. In addition, an advanced Optical Property Optimizer (Figure 4) tool helps users to understand how changes to the absorption and refractive index values impact the distribution of particle size. This considerably helps in developing powerful measurement methods.

System Maintenance

In order to ensure easy maintenance, a new cell has been designed for the Mastersizer 3000 system that eliminates the need for tightening of the measurement cell windows as well as special tools, as required with the Mastersizer 2000 system. In the Mastersizer 3000, the measurement cell is opened by simply flipping a lever, providing access to clean the inner surfaces of the cell windows. This also ensures optimum working condition of the system.

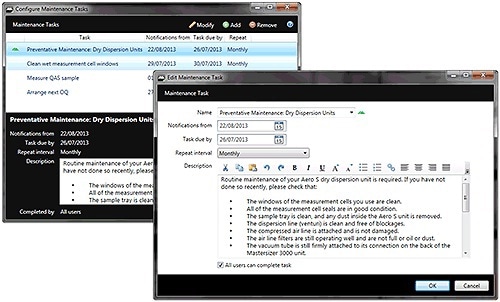

Figure 5. Maintenance scheduling tool.

In addition, the Mastersizer 3000 system features a maintenance scheduling tool (Figure 5), which allows users to set up reminders to perform preventative maintenance tasks. Users can also schedule routine service visits or annual verification checks. Also, a system health check tool makes sure that the system is linked properly and responds to software commands.

Transfer of Measurement Data and Specifications from the Mastersizer 2000 to the Mastersizer 3000

The Mastersizer 3000 system includes all the features needed to transfer methods from the Mastersizer 2000 system. The record files in the Mastersizer 2000 can be opened in the Mastersizer 2000 software. In case the information is saved in a Mastersizer 3000 format measurement file, users can reexamine their data results in the Mastersizer 3000 software through the standard analysis options provided in the Mastersizer 2000 software.

Given the fact that the Mastersizer 3000 produces similar results as the Mastersizer 2000, customers who were using the Mastersizer 2000 have migrated to the new system. As the Mastersizer 3000 has a wider measurement range compared to the Mastersizer 2000, particles can be determined which otherwise could not be viewed through the Mastersizer 2000 system.

Support for Mastersizer 2000 and Mastersizer 3000 System

Malvern Panalytical ensures that software, hardware and applications support last for seven years further than the end of a product’s lifecycle. Therefore, there would be a time period when both the Mastersizer 3000 and Mastersizer 2000 particle sizing systems will be supported simultaneously. On the other hand, the estimated lifetime of the Mastersizer 3000 system last longer than the Mastersizer 2000.

Conclusion

This article has broadly describes the capabilities of the Mastersizer 3000 particle sizing system and emphasizes how Malvern Panalytical provides application support to help users transfer methods from the Mastersizer 2000 system to the new Mastersizer 3000 system.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.