Inconel 713LC nickel based super alloy was coated with a mixture of pure silicon and aluminium powders in an organic binder based on liquid amyl acetate using a spray gun. Through a two-stage heat treatment process in an argon atmosphere, a silicon enriched nickel aluminide diffusion coating was produced. This coating is useful in high temperature applications in automotive, power generation and aircraft industries.

Instrumentation

TESCAN LYRA3 scanning electron microscope (SEM) was used for the analysis of the microstructure of the coating, as shown in Figure 1. This spectrometer consists of a focused ion beam (FIB), 3D Tomography software module and an Energy Dispersive X-ray spectrometer (EDX).

Figure 1. LYRA3 is an effective combination of SEM and FIB for exacting users. It is based on a high resolution Schottky FEG SEM column and a high performance FIB column.

Analysis Results

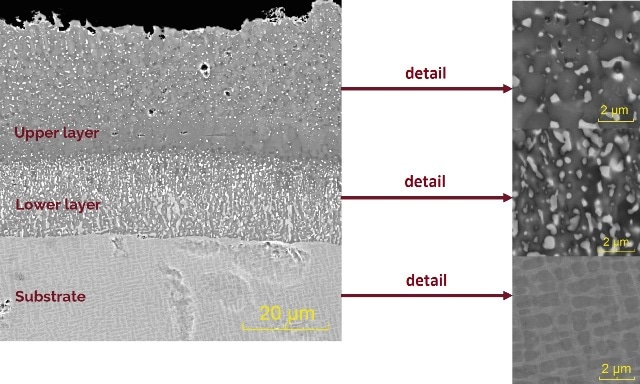

Figure 2 shows the representative cross sectional micrograph of aluminide diffusion coating that is enriched by silicon. This coating was produced at the expense of the initial paint substrate interface that was subjected to six hours of heat treatment at 1000oC.

Figure 2. Cross sectional micrograph (4Q BSE detector) of silicon enriched nickel aluminide diffusion coating formed on Inconel 713LC substrate (SEM).

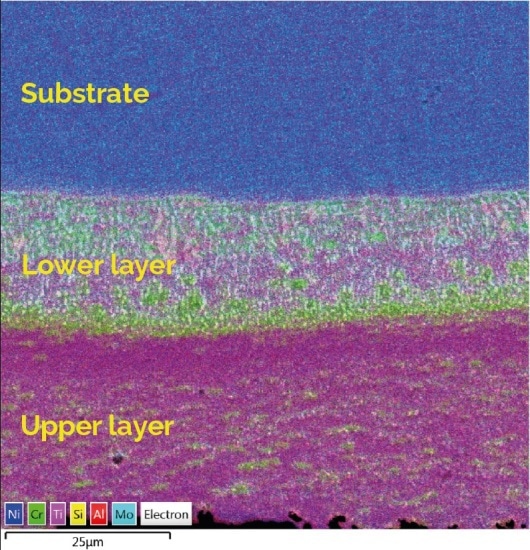

The coating is made up of two different layers or regions. The chemical composition of these layers is listed in Table 1 and the corresponding compositional map is shown in Figure 3.

Figure 3. EDX element map shows location of elements in the coating (EDX detector Oxford X-Max 80)

Table 1. Chemical composition of the coating (EDX) [at.%]

| |

Al |

Si |

Nb |

Mo |

Ti |

Cr |

Ni |

| Matrix (upper layer) |

18.8 |

5.8 |

0.9 |

2.2 |

1.3 |

14.7 |

56.3 |

| Particle (upper layer) |

9.6 |

20.3 |

3.7 |

7.3 |

1.4 |

25.1 |

32.6 |

| Matrix (lower layer) |

21.8 |

2.7 |

0.4 |

1.4 |

1.5 |

10.0 |

62.2 |

| Particle (lower layer) |

8.5 |

18.4 |

2.3 |

3.3 |

2.5 |

17.3 |

47.7 |

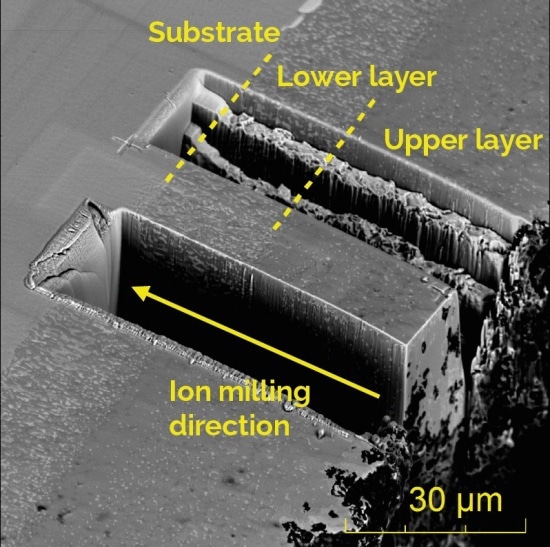

The Silicon enriched nickel aluminide diffusion coating was ion milled using the focused ion beam (FIB) technique (Figure 4). The FIB technique is suitable for gathering complete details of the internal composition of the individual layers of the coating, and also of other coatings and general surface treatments.

Figure 4. Ion milling of silicon enriched nickel aluminide diffusion coating (SEM)

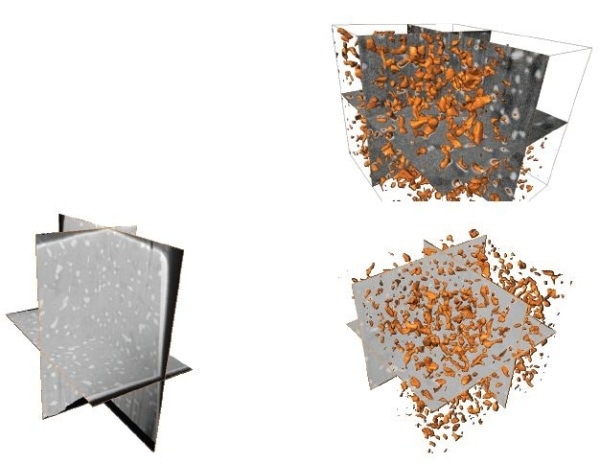

SEM-BSE micrographs were recorded during ion milling procedure and were afterwards processed via the ORS Visual software to obtain selected 2D cross sections and 3D images, respectively. This is shown in Figure 5.

Figure 5. Reconstruction of diffusion coating

Conclusion

The upper layer contained an unexpectedly high number of secondary phase particles (up to 66 vol.%). These particles are lamellae of irregular shape, with an average volume of 0.35µm3. There was a marginal decrease in the number of secondary phase particles in the upper layer, near lower layer. A thin zone of thickness 4.5µm approximately at the upper-lower layer interface indicating the formation similarities with nickel aluminide diffusion coatings produced from pure Al paints.

Lamellar precipitates in the form of a net were found in the composite lower layer, representing 74% of the layer. These precipitates are formed by at least two different types of intermetallic compounds (higher in Si and Cr concentration) and / or carbides (predominantly based on Cr, Mo and Nb). The matrix phase is generated from the upper layer by the combination of NiAl and N3Al intermetallic phases where the concentration of aluminium is decreasing marginally. This facilitates the change in the NiAl to N3Al volume fraction in the direction of the substrate.

Dr. Ladislav Celko Research Group of Materials Characterization & Advanced Coatings, Central European Institute of Technology, Brno University of Technology, Czech Republic, conducted this research.

TESCAN Group

Founded in 1991 by a group of managers and engineers from Tesla with its electron microscopy history starting in the 1950’s, today TESCAN is a globally renowned supplier of Focused Ion Beam workstations, Scanning Electron Microscopes and Optical Microscopes. TESCAN’s innovative solutions and collaborative nature with its customers have won it a leading position in the world of nano- and microtechnology. The company is proud to participate in premier research projects with prominent institutions across a range of scientific fields. TESCAN provides its clients with leading-class products in terms of value, quality and reliability. TESCAN Group is the North American arm of TESCAN Group, a multinational company established by the merger of Czech company TESCAN, a leading global supplier of SEMs and Focused Ion Beam workstations, and the French company ORSAY PHYSICS, a world leader in customized Focused Ion Beam and Electron Beam technology.

This information has been sourced, reviewed and adapted from materials provided by TESCAN Group.

For more information on this source, please visit TESCAN Group.