Image Credit: Shutterstock.com/Denis Rodin

While the revolutionary technique of three-dimensional (3D) printing has actually been a working concept for over 30 years, this technology has transformed from previously being used strictly for industrial purposes, to its current applications in a wide variety of fields.

Of the fields and professions utilizing this awe-inspiring technology include architecture, aerospace, aircraft, medical, prosthetic, dental, automobile, engineering, drone, shoes, and various consumer product makers1.

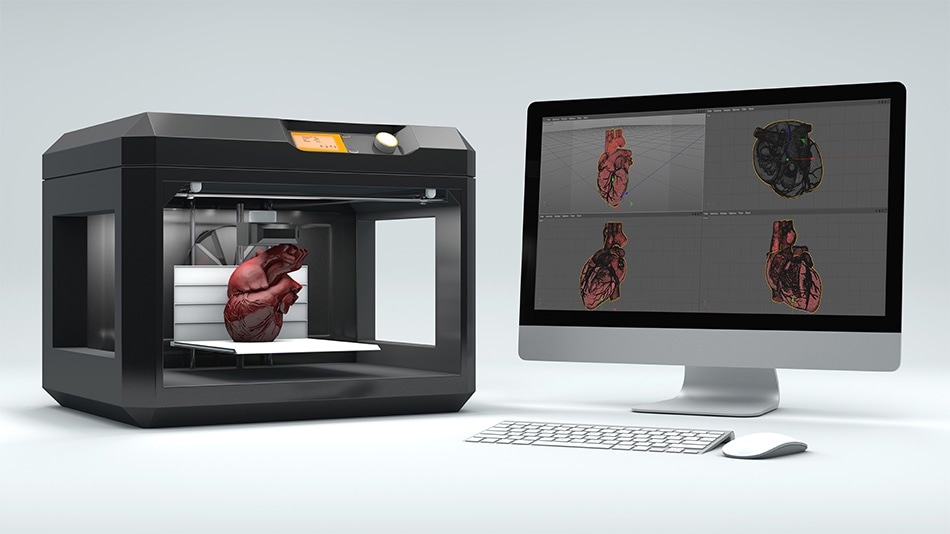

Before a product can be 3D printed, a 3D model illustrating the mathematical representation of each surface of the object must be designed through the use of computer-aided design (CAD) tools. This design template is then sliced into thin layers that are sent to the 3D printer.

The printing process can vary from this point, in which a desktop computer software will typically initiate the process by first melting a plastic material and then laying it onto a print platform, whereas an industrial 3D printer may use a laser to selectively melt metal powder at high temperature to achieve a desired finished product1.

Within the medical field, 3D printing technologies are transforming the way in which medical training is conducted, as the use of 3D models allows students to understand the full spectrum of the human anatomy in a variety of settings, while also avoiding the use of cadavers for these purposes. Similarly, 3D organ models allow for students to simulate a variety of technical procedures without putting patients at any type of risks during their learning process.

Outside of the medical education application of 3D printing, its use in advancing the way in which patients are treated in the clinical setting is astounding. Traditional ways in which physicians and other medical personnel retrieve information regarding a patient’s disease state is through the analysis of two-dimensional (2D) images2.

For cardiac cases, for example, conventional 2D methods of analysis include echocardiography (EKG), cardiac computed tomography (CT) or magnetic resonance imaging (MRI) scans. While these methods are adequate for the analysis of normal cardiac conditions, physicians face considerable challenges in converting these images into understanding the 3D spatial relationships that occur within the diseased heart, as well as other organs of interest.

Physicians treating patients suffering from complex congenital heart disease (CHD) have found success in utilizing 3D printing technology during their surgical planning process3. With a 3D replica of a patient’s specific anatomy and resultant physiology, physicians are able to make more informed decisions and precise planning prior to cutting the patient open. In this specific scenario, 3D heart models allow physicians to inspect, manipulate and hold the replica in real 3D space.

This type of intimate exposure with the patient’s organ allows surgeons to work together to decide the exact approach, incision, cannulation technique and other surgical methods necessary to correct this type of disease state3.

By having such an meticulous plan in place prior to entering the operating room, procedures that utilize 3D printing technologies often exhibit shorter operative times, fewer post-operative complications, shorter cardiopulmonary bypass time, fewer residual lesions, and quicker recovery times for the patients.

These types of outcomes are particularly beneficial for patients with CHD who have undergone multiple heart surgeries, as 3D printing reduces the risks associated with sternal re-entry due to the careful planning that occurs prior to surgery.

Researchers are currently looking at expanding the ways in which 3D printing is used in medicine, and 3D bioprinting of tissues and organs appears to be the next advancing step in this process. 3D bioprinting describes the process in which biological materials comprised of biochemical and living cells are used in forming a complex 3D functional living tissue4.

3D bioprinting has already found success in the generation and transplantation of skin and bone tissues, as well as vascular grafts and cartilaginous structures. Researchers are hopeful that further 3D bioprinted tissues can be constructed for not only transplantation purposes, but to also advance drug delivery techniques, toxicological analysis of agents, as well as basic medical research

References:

- "What Is 3D Printing? The Definitive Guide." 3D Hubs. Web. https://www.3dhubs.com/what-is-3d-printing#how-does-3d-printing-work.

- "Using 3D Printing to Treat Complex Structural Heart Disease." Stratasys Blog. 23 Feb. 2017. Web. https://www.stratasys.com/en/resources/blog/3d-printing-heart-disease/.

- Valverde, Israel. "Three-dimensional Printed Cardiac Models: Applications in the Field of Medical Education, Cardiovascular Surgery, and Structural Heart Interventions." Revista Espana De Cardiologia (English Edition) 70.4 (2017): 282-91. Web.

- Murphy, Sean V., and Anthony Atala. "3D Bioprinting of Tissues and Organs." Nature Biotechnology 32.8 (2014): 773-85. Web.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.