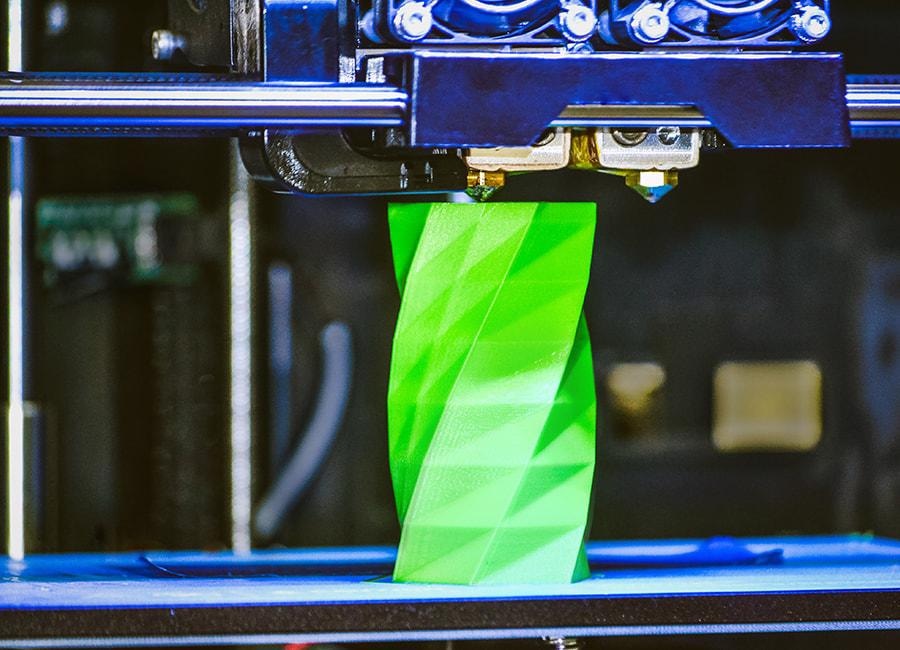

3D printing has taken off as a niche manufacturing method, enabling consumers to design and build their own goods. As such, it now holds an important place in the manufacturing industry. Objects can be built in almost any format the consumer desires, and it has moved on from the early limitations of certain polymer groups as the building material. Now it is a potential tool in many industries, including bone and organ replacements, meat manufacture, and even customizable bakery.

If you’ve designed a product in a CAD package and then you print it, one concern will be whether what has been printed is what you designed. In many cases, you’ll need your printed object to be dimensionally accurate and iterations of printing your design are almost inevitable to adjust the printing settings to obtain a product that is dimensionally accurate. Accurate digital assessment of physical dimensions thereby becomes a necessity. A Volscan Profiler provides such a solution - the Volscan Profiler is a benchtop laser-based scanner that measures the volume, density, and dimensional profiles of solid products. The rapid 3-dimensional digitization of products enables the automatic calculation of several detailed dimension related parameters, the results of which may be mathematically manipulated for immediate use or future retrieval in a variety of data formats for your printed objects.

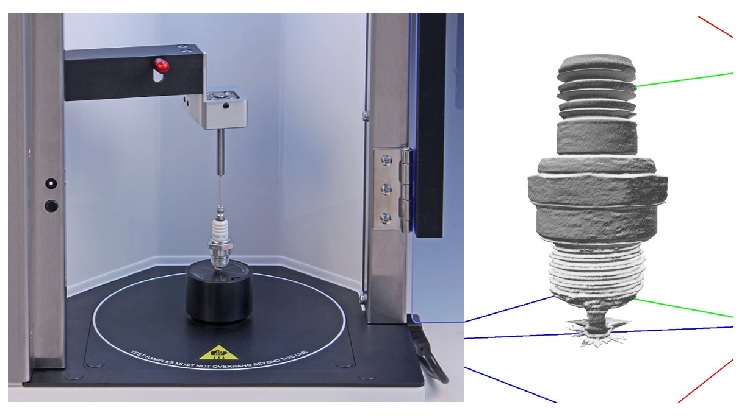

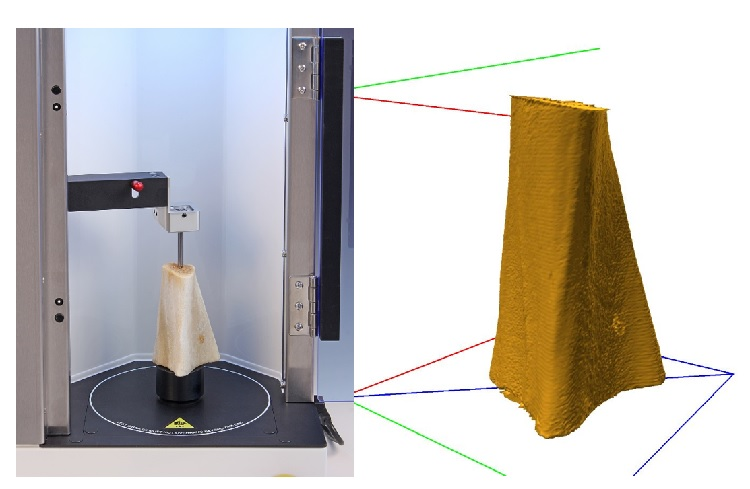

Volscan Profiler models for measurement of Volume, Density, and Dimensional Profiles.

Typical ways of mounting samples in order to scan and measure their dimensional profiles:

Mechanical component sample ready for scanning and an archived scan of the sample.

Bone sample ready for scanning and an archived scan of the sample.

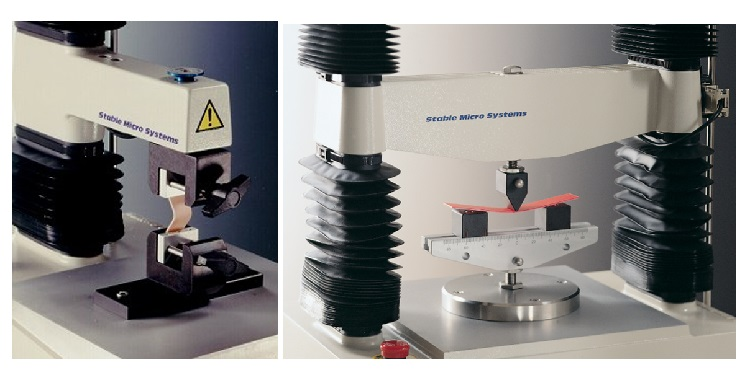

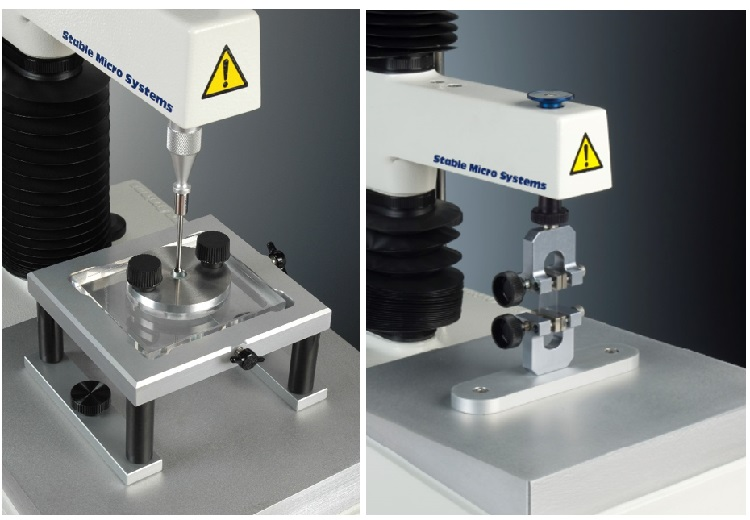

As well as the measurement of dimensional profiles, Stable Micro Systems also manufactures instruments that measure the tensile and compressional properties of 3D printed parts. As with any manufacturing innovation, the end product must go through a quality control process to assess its physical properties. A Texture Analyser is a crucial part of this procedure, giving a reliable way to test the mechanical properties of 3D printed objects by applying a choice of compression, tension, extrusion, adhesion, bending or cutting tests to measure a product’s physical properties e.g. tensile strength, flexural modulus, fracturability, compressibility, to name but a few.

Example of how 3D printing materials can be tested - Extrusion

The printability of materials used in extrusion-based 3D printing is one of the most important properties, especially when fabricating objects with architectural complexities. This parameter is influenced by several factors (temperature, components, and additives) which makes thorough evaluation and classification challenging. Interest in 3D printing for biomedical applications is now increasing and the pharmaceutical industry is starting to explore how 3D printing can help us to deliver better medicines. Achieving reproducibility in the 3D printing of biomaterials requires a robust polymer synthesis method to reduce batch-to-batch variation as well as methods to assure a thorough characterization throughout the manufacturing process. Particularly biomaterial inks containing large solid fractions such as ceramic particles, often required for bone tissue engineering applications, are prone to inhomogeneity originating from inadequate mixing or particle aggregation which can lead to inconsistent printing results. The production of such ink can be optimized to assure homogeneous and reproducible printing results by using a TA.XTPlus Texture Analyser to perform extrusion force measurements to predict the printability of inks. To read an example publication of this texture analyzer application at ETH Zurich, click here.

Forward extrusion test on a Texture Analyser.

Example of how 3D Printing Materials can be Tested - Compression

Due to the low price of 3D printing equipment and its versatility, materials such as antioxidant PLA composites containing lignin can be used in hospitals to print wound dressings for patients on demand. 3D printing can also potentially benefit plastic and reconstructive surgeries by fabricating patient-specific tissue replacements with tissue-like functions and mechanical properties. A Texture Analyser can be used to perform compression testing on samples to characterize their mechanical properties which are important for their structural integrity. To read an example publication of this texture analyzer application at the University of Nottingham, click here.

Unconfined compression on a Texture Analyser.

Example of how 3D Printing Materials can be Tested - Mucoadhesion

Microdevices for oral drug delivery have so far been fabricated as square or cylindrical reservoir structures with a localized and unidirectional release. The fabrication is usually carried out using sophisticated and costly microfabrication techniques. However, 3D printing of micro reservoirs on sacrificial substrates can allow the devices to be accurately arranged in predetermined patterns, enabling implementation into batch production schemes in which the fabrication of the devices is linked to processing steps such as automated drug loading and sealing. Moreover, design and 3D printing of alternative geometries of mini reservoirs featuring anchor-like surface structures for improved mucoadhesion and intestinal retention are possible. Using a Texture Analyser to perform mucoadhesion tests allows measurement of increased mucoadhesion of these devices up to two-fold compared to a nonstructured control. The structuring also leads to a strong bias in mucoadhesion in different orientations, which can facilitate a correct orientation of the devices and so lead to an unidirectional release of drugs toward the intestinal mucosa for increased drug uptake. To read an example publication of this texture analyzer application at the Technical University of Denmark, click here.

Mucoadhesion Rig on a Texture Analyser.

Example of how 3D Printing Materials can be Tested – Flexure and Bending

3D printing provides a new approach to fabricating drug eluting implantable medical device products because it permits a flexible manner to extrude complex and customized shapes of tissue scaffolds. Considering the simplicity it can be easily transferred to a clinical setup, where implants could be designed on demand to fulfill patients’ needs after surgery. These implants may be suited for the delivery of drugs for localized treatment. For example, chemotherapy agents, antibiotics, or local anesthetics. Alternatively, they could be tailored by coating them for prolonged drug delivery for the treatment of chronic conditions.

Compared with other printable biomaterials, polyurethane elastomers have several merits, including excellent mechanical properties and good biocompatibility. However, some intrinsic behavior, especially a high melting point and slow rate of degradation, hamper their application in 3D printed tissue engineering. The development of a 3D printable amino acid modified biodegradable waterborne polyurethane means that the flexibility of this material endows better compliance with tissue during implantation and prevents high modulus transplants from scratching surrounding tissues. Using a Texture Analyser to perform flexibility (3 point bend) measurements on 3D printed samples allows assessment of whether this can be used as an alternative biomaterial for tissue engineering with low-temperature printing, biodegradability, and compatibility. To read an example publication of this texture analyzer application at the University of Science and Technology Beijing, click here, or click here to see similar work at Queen’s University Belfast.

Flexibility and 3 point bend testing on a Texture Analyser.

Example of how 3D Printing Materials can be Tested – Puncture, Elongation, and Tension

Orodispersible films (ODFs) are promising dosage forms for children or elderly people who may face swallowing problems with solid oral dosage forms. By printing active pharmaceutical ingredients onto orodispersible films, the flexibility of drug dosing is increased and provides the potential for personalized medicines. Warfarin is an example narrow therapeutic index drug that requires personalized dosing which is currently not achieved by marketed products. Extrusion 3D printing can be utilized to produce transparent, smooth, and thin, yet flexible and strong orodispersible films containing therapeutic doses. Using a Texture Analyser the films can have their burst strength and flexibility properties measured as part of their all-important physical characteristics that could impact their usability.

To read an example publication of this texture analyzer application at the Heinrich Heine University Dusseldorf click here for similar work carried out at Åbo Akademi University.

Burst strength, tensile strength, and film flexibility on a Texture Analyser.

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.