Texture is becoming a leading driver for taste perception in food, particularly sweets or candies. Extra crunchy, super crispy – texture descriptions on new products have become more elaborate over the last few years along with the increasing use of superlatives to convey the “ultimate texture experience”. Visual texture descriptions are also receiving more prominence on packaging, while the size of the texture-evoking words is also increasing. Texture has become more dominant due to bigger inclusions such as chunks, clusters and nuggets, more innovative shapes have evolved to help achieve extra crunch or improved taste and the idea of providing a multitude of textures all at once, such as chewy, smooth and crunchy.

Once designed, however, the texture will need to be quantified because after it’s bought and desired any new confectionery product will then survive only as long as the manufacturer is able to provide it at consistent quality to meet the consumer’s expectations. Information about the product’s textural properties can be obtained by texture analysis testing using a TA.XTplus/TA.HDplus Texture Analyser. Texture Analysis can play a pivotal role in measuring consistency in quality control, comparing textural features of competitor products as well as analyzing and controlling the desired textural features of any new or existing product for the market. The market is exciting and playful but loyalty is key and quick to change so you’ll want to make sure that the product quality is optimally measured and monitored to minimize failure.

How to Measure Break, Snap or Bend

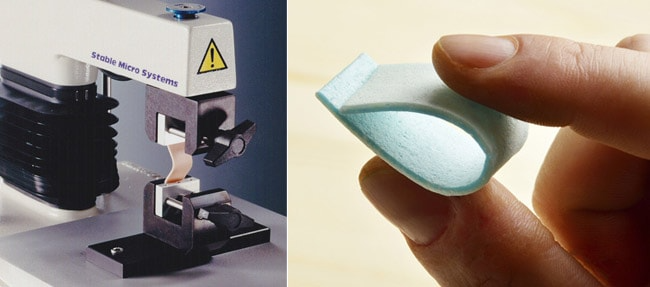

Many confectionery products exist in a solid bar form and as such their Snap Strength or Force to Break are of interest. A three point bend test mimics the breaking of a bar in half by supporting a bar with guides positioned a suitable distance apart and pushing down centrally with a curved blade from the top. A low force is indicative of a product that requires little effort by the consumer to break whilst the distance at the break point indicates the degree of flexibility, or conversely brittleness, that the product possesses.

Whilst some confectionery products are designed to have a ‘quick break’ with a crispy, snapping sound, others, such as gelled or chewing gum stick-like products, have an expected flexibility as part of their known textural character. This flexibility can be measured by holding the product in tensile grips and cycling down and up continuously until the product shows failure. Such a test is commonly used to assess changes in flexibility of chewing gum sticks over periods of storage.

Caption: 3 point bend rig performs an imitative test to what consumers do

Caption: Tensile grips can perform a cyclic bending test to assess flexibility

How to Measure Firmness and Springiness

Gummy candies are part of the large category of confectionery products such as jellies, marshmallows, licorice, pastilles, and wine gums. This category includes a diverse array of different sizes, flavors, shapes and textures depending upon the gelling agent which is chosen. Desired textures – brittle or flexible, soft or firm – will determine the type of gelling agent used for a specific application.

A measurement of both firmness and springiness (elastic recovery) can be made using a cylinder probe larger than the sample being tested. By using a 'Hold Until Time' test a chosen compression distance is held for a chosen period of time, over which the products recovery is recorded. A simple calculation can be made to analyze the data. A major change during the aging of elastic confectionery products is an increased resistance to compression (firming) and a loss of recovery when compressed, i.e. decreased springiness.

Caption: A cylinder probe can perform a compression test to measure firmness and springiness

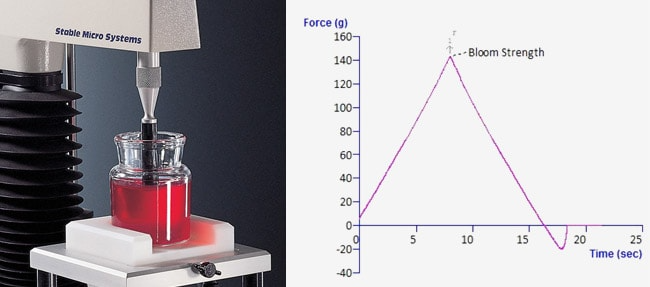

How to Measure Gel Strength, Rupture Force & Elasticity

The measurement of gel strength is of widespread interest in the manufacture of confectionery products. Gel properties such as elasticity and rupture force are important in the development of novel products with diverse textural differences.

Using a cylinder probe (typically 1” radiused for pectin and 0.5” for other gel types) the probe is lowered into the gelled system at a fixed rate to a chosen distance which does not lead to fracture of the gel surface. The strength of the gel is usually assessed as the force to reach the chosen distance. Standard probes such as that required for gelatine testing (according to the ISO Standard) are also available for the assessment of Bloom strength where the force at 4mm penetration is taken as its Bloom value. Should it be necessary to measure rupture force, gel brittleness/elasticity, this test (for the determination of Bloom Strength) can be adapted to continue penetration after 4mm to e.g. 15mm into the bloom jar.

Caption: Bloom/Gel strength testing and a typical graphical result

How to Measure ‘Stretchiness’

Caption: Roller grips are able to secure the sample in order to measure its stretching properties

Kids love the feeling of taking a bite of a gummy lace and pulling it away from their faces. At some point during this stretching, the lace will break but the action will have been a desirable expectation of this type of product. Many sugar confectionery products are manufactured by the cut-and-wrap process where a ‘rope’ of the product is drawn out in tension. Therefore, it seems appropriate to use a tension test to assess the tensile strength and elongation properties of a product. As with all tensile tests, the art of a valid and useful test comes in the successful holding of the sample in order to perform the test and avoid breakage of the sample at the grip face which involves the correct choice from a range of tensile grip solutions to suit the length, thickness and texture of the sample.

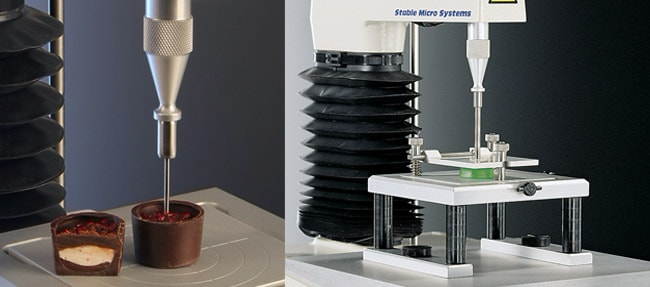

How to Measure the ‘Bite’ Force

Caption: A variety of blades are available to measure the force to ‘bite’ through a product

Consider the front teeth in a line – their action can be imitated by the use of a blade on the Texture Analyser. The ‘Bite force’ property can be assessed with a Craft Knife if the sample is homogeneous or a Kramer Shear Cell if non-homogenous. A sample of fixed height and width is placed on the testing platform and the maximum force and area under the positive region of the curve obtained as measures of hardness or ‘bite characteristics’. For larger samples a standard blade may be used.

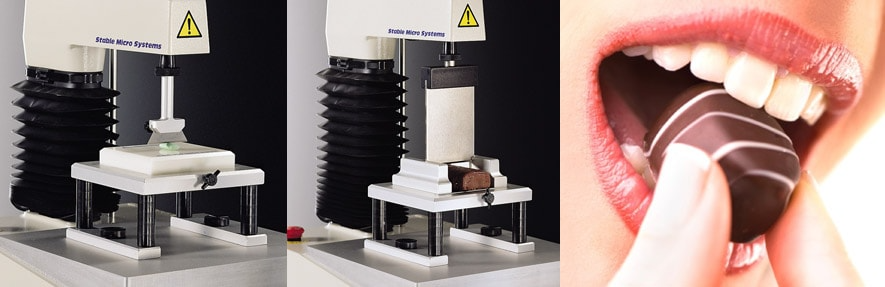

How to Measure Hardness, Stickiness and Multi-Texture Products

Caption: Penetration tests can measure firmness, stickiness and multi textures within a product

Hardness/firmness and stickiness are the most important properties of plastic solids such as fudge, toffee, marzipan, chocolate or fondant. Whilst the hardness can provide the means to assess effects of different formulation on the sample, the stickiness may provide a useful measurement such as the tooth pulling potential of a confectionery product.

Hardness and stickiness can be measured using a relatively small cylinder probe which performs a penetration test to a chosen distance into the sample. Hardness is commonly the force to penetrate to the chosen distance whilst stickiness is the work/force necessary to overcome the attractive forces between the surface of the sample and the surface of the probe used for the measurement. In order to successfully measure the stickiness of a product the sample needs to be held down to prevent it from being lifted on the end of the test probe upon its attempt to withdraw from the product. A Confectionery Holder is an example of one such means of supporting a sticky sample. Using a small cylinder probe, the probe is effectively able to differentiate between the mechanical resistances offered by different phases of a multi-texture product which offers interesting textural variation to the consumer.

This article only covers a selection of typical tests for confectionery products but other methods are available for the measurement of variable textured products, the measurement of product consistency, surface stickiness, deposit tailing and stringiness with an extrusion test and the measurement of crispness of single or multi-particle products.

For a full summary of typical texture analysis tests that can be performed on confectionery products:

Confectionery Texture Measurement & Analysis