.jpg) By Susha Cheriyedath, M.Sc.Apr 13 2022

By Susha Cheriyedath, M.Sc.Apr 13 2022Due to the ever-increasing demand for energy, the demand for nuclear fuel has also increased, which has further created a significant increase in the requirement for post-irradiation examination (PIE) techniques.

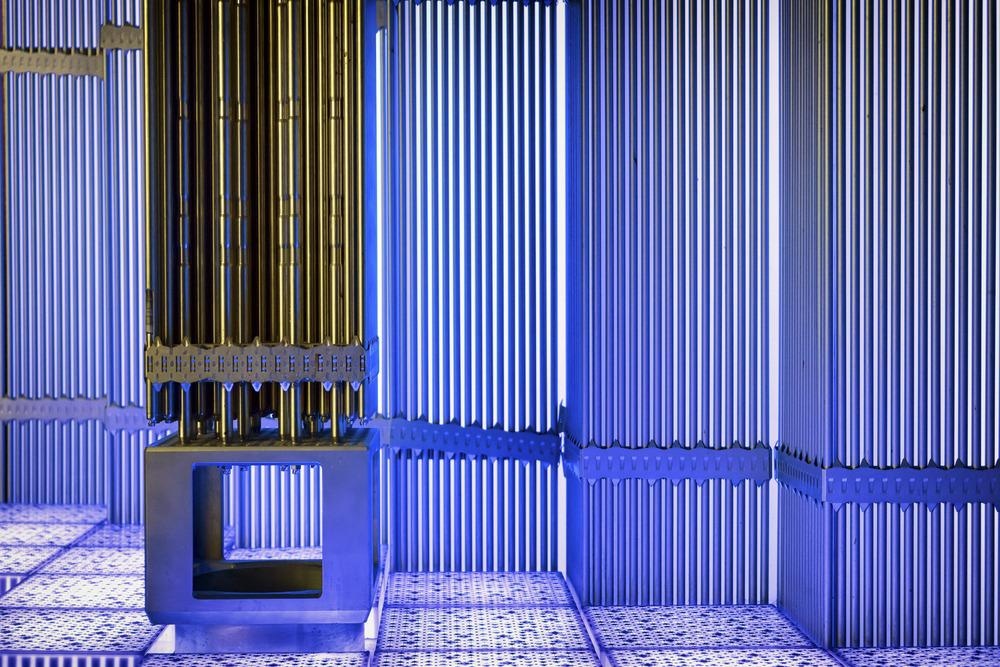

Image Credit: Parilov/Shutterstock.com

PIE Techniques

The study of nuclear fuel and associated materials such as fuel rods, water rods, grids, and channel boxes is performed using PIE techniques with the aim of designing an efficient fuel that can endure operating conditions under normal, transient, and accidental conditions. The examination of irradiated fuel rods and other materials is usually done at a hot cell laboratory and the data is utilized by fuel developers, manufacturers, operators, regulators, material scientists, and metallurgists for fuel improvement and ultimately to enhance operating efficiency and reliability.

The Rationale for Using PIE Techniques

The life cycle of nuclear fuel material is highly complex and it changes during storage, operation, and unloading. The materials in fusion nuclear reactors are exposed to high energy (14MeV) neutrons, which cause radiation damage to materials. Thus, to safely operate a fusion reactor, the detailed behavior of material degradation with respect to a 14 MeV neutron dose must be understood.

PIE techniques are needed for the characterization and assessment of the fuel, either in a non-destructive or destructive manner, in a cost-effective way. Such examinations play a pivotal role in assessing the failure mode that occurs during normal use and the behavior of fuel during an accident.

The information is also used to ensure fuel quality and the development of fuel with the desired specifications. The characterization of completely irradiated fuel will involve elemental and isotopic analyses coupled with chemical speciation and structure determination. These studies will be based on the use of advanced spectroscopic techniques, hot-laboratory instrumentation, and synchrotron radiation.

The PIE Process and Associated Challenges

Non-destructive PIE includes visual inspection, detection of failed fuel rods, measurement of dimensions, oxide layer measurement, gamma scanning and tomography, neutron and X-ray radiography, while destructive techniques include microstructural studies, elemental and isotopic analysis, and measurement of physical and mechanical properties.

The imaging techniques show, elaborate, and report PIE data through an image file and streamline the reporting process. In visual inspection and dimension, detailed information can be gathered about geometrical changes in the fuel assembly and peripheral fuel rods. Gamma scanning devices also provide burnup profiles for the fuel assembly and rods.

To understand the fuel behavior, the measurement of injected energy in a fuel rod during a fast transient is very important as it helps calculate the thermal level achieved during the test. Such estimations are based on neutron flux integration, although compromised with some uncertainties due to neutron flux variation.

Image Credit: FooTToo/Shutterstock.com

These challenges were successfully overcome by using isotopic analysis. Researchers have measured short-time pulse energy deposits in the fuel rod slice and the energy released during such irradiation by measuring the 140Ba isotope content. This method is certainly the best, but it cannot be applied in any test reactor because of the short time needed for the measurement.

Recent Developments

Advanced PIE techniques support the understanding of the mechanisms of fuel behavior under irradiation. Such techniques include three-dimensional (3D) tomography, secondary ion mass spectrometry, laser flash, and high-resolution transmission and scanning electron microscopy.

Neutron radiography and emission tomography are instrumental in the investigation of inner structure and fission product distribution in irradiated rods. This method can further reveal fuel rod degradation or failures initiated by hydrogen pick-up or fuel relocation and cracking. However, the method is compromised by the availability of an adequate neutron source thus limiting its use in a normal hot cell laboratory.

3D tomography is also a fast emission tomography of fuel rods in hot cells, which reduces scanning time and improves tomography efficiency. This technique has been successfully applied to fuel rods operated under standard as well as transient conditions. Mechanical profilometry is one of the best methods for the analysis of changes in large-scale fuel rod diameters. Tests performed by researchers on unirradiated fuel using a micro-profilometer provided high accuracy with a precision of 2µm in diameter.

Conclusion

To conclude, PIE technologies are needed for appropriate fuel examination to ensure safeguard inspections, spent fuel management, and fuel service activities. These techniques will also support the nuclear R&D program associated with fuel rod verification. Fuel design groups and utility groups are making constant efforts for achieving higher burnup, higher power, and high integrities of the fuels under transient and accident conditions. PIE techniques are instrumental to ensure the safety of nuclear plants and improve fuel performance.

More from AZoM: Electro-Spark Deposition Applied to Metal Alloys

References and Further Reading

Cappia, J.M. Harp, Post irradiation examinations of low burnup U3Si2 fuel for light water reactor applications, J. Nucl. Mater. 518 (2019) 62–79. https://www.sciencedirect.com/science/article/pii/S0022311518317392

Jason Schulthess, Nicolas Woolstenhulme, Aaron Craft, Joshua Kane, Nicholas Boulton, William Chuirazzi, Alexander Winston, Andrew Smolinski, Colby Jensen, David Kamerman, Daniel Wachs, Non-Destructive post-irradiation examination results of the first modern fuelled experiments in TREAT, Journal of Nuclear Materials, Volume 541, 2020, 152442, ISSN 0022-3115, https://doi.org/10.1016/j.jnucmat.2020.152442.

Recent Developments in post-irradiation examination techniques for water reactor fuel, Proc. Tech. Committee Meeting, Cadarache, France, 17-21 October (1994). https://www.iaea.org/publications/5468/recent-developments-in-post-irradiation-examination-techniques-for-water-reactor-fuel

Y.Park, et. al., "Nuclear Fuel Poolside Inspection Technology Development", KAIF/KNS Annual Conference (2003).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.