By Taha KhanReviewed by Lexie CornerJan 9 2025

By Taha KhanReviewed by Lexie CornerJan 9 2025

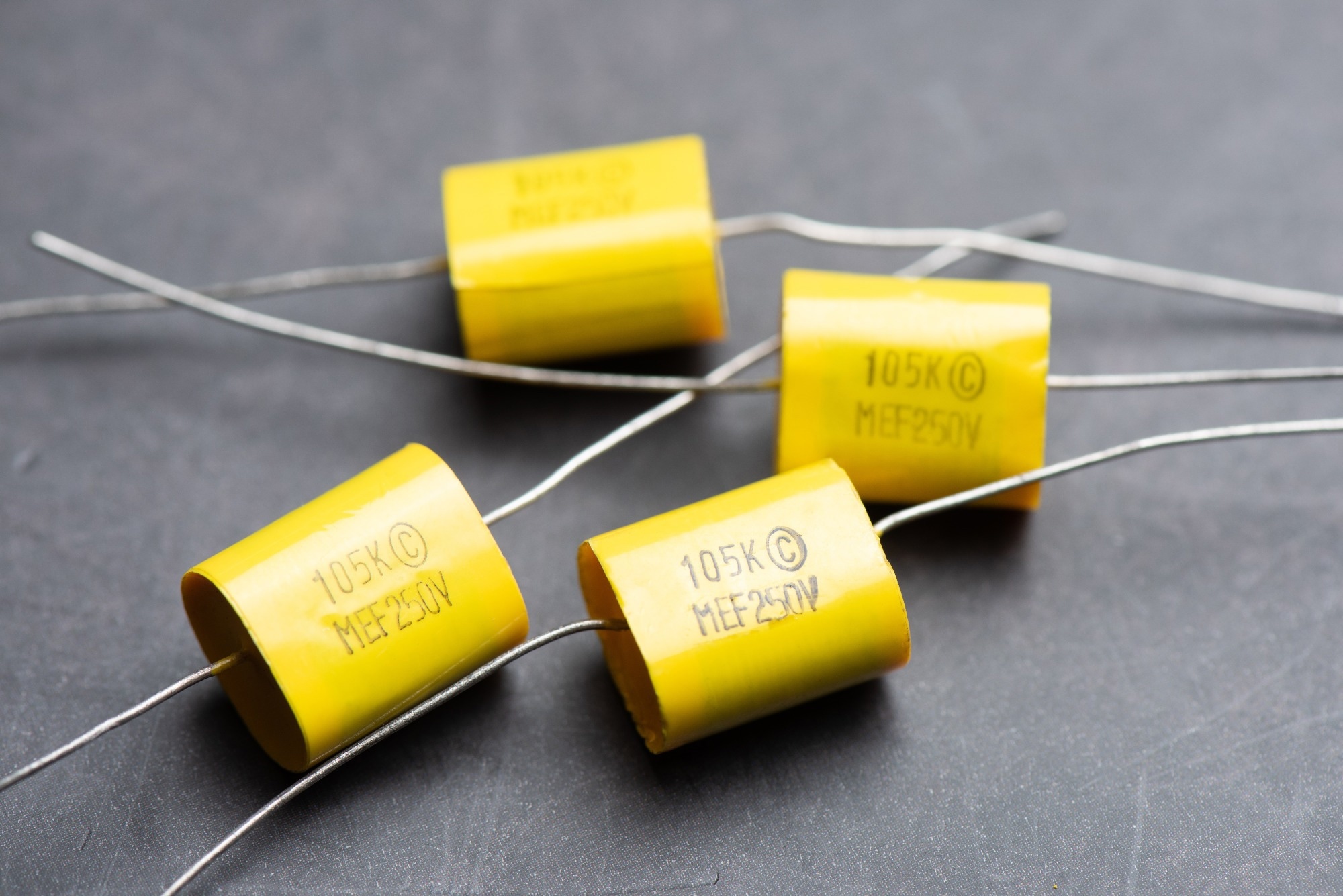

Film capacitors are passive electronic components that store electrical energy in an electric field between two conductive plates separated by a dielectric film. These devices are integral to modern electronics, offering tailored performance for diverse applications, including power factor correction in AC circuits, noise suppression in automotive systems, high-frequency filtering in telecommunications equipment, and precision timing in industrial controls.

Image Credit: Nor Gal/Shutterstock.com

Materials Used in Film Capacitor Production

The choice of dielectric material significantly influences the performance of film capacitors in high-frequency applications, impacting energy storage density, dielectric strength, and overall efficiency. Various dielectric materials, including polyesters, polypropylene, and polycarbonate, exhibit distinct properties that cater to specific operations.

Polyester

Polyester is widely used in the production of film capacitors due to its cost-effectiveness and versatility. It offers a good balance of electrical performance and mechanical stability, making it suitable for a wide range of applications.

Its properties include relatively high dielectric strength, low dissipation factor, and excellent thermal stability, enabling polyester film capacitors to perform reliably in various types of electronic circuits.1

Polypropylene

Polypropylene (PP) enhances the performance of film capacitors across various applications, particularly in power electronics and high-frequency environments. It boasts high breakdown strength (up to 865 MV m⁻¹) and energy density (8.2 J cm⁻³), making it a preferred choice for modern capacitor designs. Surface modifications, such as parylene deposition, further improve its energy density by 40 % to 50 %.2, 3

Polypropylene is particularly effective in high-voltage direct current (HVDC) applications and metallized film capacitors. Its self-healing properties and long-term reliability ensure consistent performance in challenging electrical environments.4

Polycarbonate

Polycarbonate (PC) is known for its stability and durability, particularly in applications requiring reliable operation at higher temperatures. Researchers have explored combining PC with nylon to address limitations in traditional biaxially oriented polypropylene (BOPP) capacitors, which are restricted to a temperature rating of 85 °C.

PC/nylon multilayer films (MLFs) demonstrate effective performance at temperatures up to 120 °C, using the higher melting point of nylon and the glass transition temperature of PC at 145 °C. Packaged PC/nylon-12 MLF capacitors also exhibit self-healing properties, ensuring long-term reliability.5

Conductive Plates

Conductive plate materials are critical to the operation of film capacitors. Aluminum or copper foils are typically used for their exceptional electrical conductivity and mechanical properties.6

These materials ensure efficient energy storage and discharge while offering flexibility to withstand operational stresses, making them ideal for the structural foundation of film capacitors.

Metalized Film Capacitors

Metallized film capacitors combine a compact design with enhanced efficiency. A thin metal layer deposited on the dielectric film contributes to improved electrical performance and effective thermal management. These capacitors are crucial in applications like electric vehicle (EV) motor controllers, where they attenuate ripple currents and support high-temperature operation.

Recent research introduced a modeling method based on finite element simulation to evaluate the thermal and electrical properties of multilayered metallized thin films. This approach highlights their potential to mitigate material aging and optimize thermal distribution, addressing the demands of advanced EV systems for compact, high-performance solutions.7

The Manufacturing Process

The manufacturing process of film capacitors involves several critical steps, including film preparation, winding techniques, and sealing.

Film Preparation

The dielectric material is extruded into thin sheets tailored to the specific electrical properties required for capacitor performance. These sheets are then wound together with conductive foils to form the core of the capacitor.

Recent advancements in materials science, such as the development of high-k polymer composites, have enhanced film preparation, improving dielectric constant, energy density, and breakdown strength while minimizing dielectric loss. The integration of novel materials, including metal oxides and 2D conductors, has further elevated performance.8

Winding Techniques

Winding techniques significantly influence the reliability and performance of film capacitors. Two primary methods are used:

-

Insert Tab Winding: Small copper tabs are strategically inserted at intervals to connect electrodes, ensuring efficient electrical connectivity and minimizing internal inductance.9

-

Extended Foil Winding: One foil extends beyond the edges of the dielectric film, reducing self-inductance and enhancing current discharge efficiency. This design enables capacitors to handle higher power outputs while maintaining low inductance. Combined with polypropylene dielectrics, extended foil configurations meet the stringent requirements of pulse power applications, offering fast discharge times and reliable performance. These features make them particularly suitable for compact, high-performance systems like particle accelerators and other high-repetition rate technologies.10

Sealing and Encapsulation

Sealing and encapsulation are essential steps in capacitor manufacturing, designed to protect internal components from damage and external elements. This process typically involves enclosing the capacitor in a protective case made of materials like plastic, resin, or silicone elastomer potting compounds.

For example, aluminum electrolytic capacitors benefit from silicone elastomer encapsulation, which minimizes electrolyte leakage and reduces degradation under thermal and electrical stress.11

Thermosetting resins and plastic molding can also be tailored to specific application requirements, such as improving mechanical strength or enhancing resistance to environmental factors like moisture and temperature fluctuations. These measures ensure the durability and reliability of capacitors in diverse operating conditions.

How We Make Capacitors | Film

Quality Control and Testing

Quality control is a vital aspect of capacitor manufacturing. Rigorous testing protocols assess critical performance parameters, including capacitance value, equivalent series resistance (ESR), insulation resistance, and temperature coefficient. These evaluations ensure that capacitors meet precise electrical specifications and perform reliably across diverse operating conditions.

Film capacitors are integral components in modern electronics. By using advanced materials, innovative winding methods, and stringent quality control processes, manufacturers continue to enhance the reliability, efficiency, and versatility of these essential devices to meet evolving market demands.

Optimizing Thin-Film Deposition with UV Ozone Cleaning

References and Further Reading

- doEEEt. (2019). Types of plastic film capacitor dielectrics. [Online] doEEEt. Available at: https://www.doeeet.com/content/plastic-packaging-for-space/types-of-plastic-film-capacitor-dielectrics/ (Accessed on December 15, 2024)

- Li, W., et al. Ultrahigh Energy Density Achieved at High Efficiency in Dielectric Capacitors by Regulating α‐Phase Crystallization in Polypropylene Films with Fluorinated Groups. Advanced Functional Materials. https://doi.org/10.1002/adfm.202410959

- Liu, H., Du, B., Xiao, M., Ran, Z., Tanaka, T. (2022). Breakdown Strength and Energy Density Improvement of Polypropylene by Parylene Deposition for Film Capacitor. IEEE Transactions on Dielectrics and Electrical Insulation. https://doi.org/10.1109/TDEI.2022.3173496

- Xiao, M., Du, B., Xu, R., Ran, Z., Liu, H., Xing, J., Fan, K. (2021). Improvement of Dielectric Properties of Polypropylene Film for HVDC Metallized Film Capacitors. Polymer Insulation Applied for HVDC Transmission. https://doi.org/10.1007/978-981-15-9731-2_25

- Li, Z., et al. (2019). High dielectric constant polycarbonate/nylon multilayer films capacitors with self-healing capability. ACS Applied Polymer Materials. https://doi.org/10.1021/acsapm.9b00099

- Zhao, P., Xiong, L., Li, X., Guo, Y., Xie, Y., Du, X. (2023). Research and Application Progress of Conductive Films in Energy Storage Devices. Advanced Materials Technologies. https://doi.org/10.1002/admt.202300194

- Kuang, K., Guo, X., Li, X., Xi, X., Fang, H., Li, C. (2023). A Method for Electrical and Thermal Modeling of Thin Film Capacitors for Electric Vehicles from Multiscale Perspective. 2023 26th International Conference on Electrical Machines and Systems (ICEMS). https://doi.org/10.1109/icems59686.2023.10344902

- Liu, L., Qu, J., Gu, A., Wang, B. (2020). Percolative polymer composites for dielectric capacitors: a brief history, materials, and multilayer interface design. Journal of Materials Chemistry A. https://doi.org/10.1039/D0TA05876A

- Molchanov, D., Lavrinovich, I., Artyomov, A., Rybka, D. (2018). New low-inductance capacitor-switch assembly. In Journal of Physics: Conference Series. https://doi.org/10.1088/1742-6596/1074/1/012110

- Ennis, JB., Kerrigan, R. (2017). 30–100kV plastic case capacitors for Ltd's, Marx generators, and other pulse power applications. 2017 IEEE 21st International Conference on Pulsed Power (PPC). https://doi.org/10.1109/PPC.2017.8291211

- Parsa, E. (2014). Effect of encapsulation on electrolyte leakage in aluminum electrolytic capcitors under constant thermal and electrical loading. [Online] University of Maryland. Available at: https://doi.org/10.13016/M2JK5C

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.