Knowing the viscosity of a lubricant is critical for condition monitoring. As a result, field-based users need portable viscometers to immediately assess critical equipment while working on-site. Portable viscometer options currently require solvents, density and temperature measurements to arrive at results. They do not correlate with laboratory viscometers, which means the collected data is not co-trended. In-use oils, in particular, make precise viscosity measurements by any technique a challenge given their particulates, water and combustion by-products.

Image 1. SpectroVisc Q3000

The Q3000 portable solvent-free viscometer is a true kinematic heated field viscometer available for condition monitoring. Based on the patented split cell capillary technique, the technology provides a dramatic leap forward in simplifying the reporting of viscosity (in Centistokes at 40˚C). With an accuracy of 3%, reproducibility on a NIST-traceable viscosity standard, the new tool encourages end users to compare its performance on used oils with traditional laboratory viscometers.

Image 2. SpectroVisc Q300

Technology Performance Challenges

The process of comparing results from one instrument to another involves several factors:

- Wide variability in the performance of in-use oils

- Variability in the performance of the viscometers

- Variability in application requirements

Rather than come up with a single benchmark comparing portable and laboratory viscometers, users need a method for determining whether a portable viscometer will “do the job” given their particular requirements. We present one such method as a recommended best practice and show the results we obtained when we compared the field viscometer to a laboratory system.

Test Procedure

For this comparison, SPECTRO used a SpectroVisc Q3000 as an example of a portable viscometer and a SpectroVisc Q300 as the laboratory viscometer. The SpectroVisc Q3000 is a portable, solvent-free kinematic viscometer developed for applications where immediate results are required. The SpectroVisc Q300 is a capillary (Modified Zeitfuchs) tube viscometer designed for laboratory analysis.

Both instruments measured the viscosity of a number of samples, and the measurements were compared from instrument to field viscometer. Two series of comparisons were made. The first set of samples consisted entirely of NIST-certified standards and the second sample set consisted of used oils.

Each sample was run three times, each on the SpectroVisc Q3000 and the SpectroVisc Q300 with kinematic viscosity readings taken at 40˚C. Results from both sets were averaged and compared.

The application of NIST standards allows the accuracy of both approaches to be compared and also to see how closely the portable Q3000 reproduces results consistent with those of the laboratory. The used oil measurements, on the other hand, are for real-world, immediate results. Here the actual viscosities are unknown, making absolute accuracy comparisons impossible. The goal is to determine how the portable tool compares to the laboratory instrument across a spectrum of widely varying samples. If the results from the two approaches are “close enough” for the user, the portable tool can be substituted for the analytical instrument.

Figure 1 Performance of Q3000 compared to SpectroVisc Q300 over range of certified viscosity standards. The Q3000 performs consistently across the calibrated range, with a relative standard deviation less than 2%.

Sample Results

Figure 2 Sample results

Results Discussion

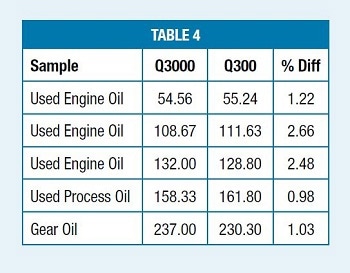

Figure 1 shows the performance of the Q3000 portable tool compared to the Q300 bench-top instrument over a range of certified viscosity standards. Table 1 compares the Q3000 against the NIST references. Table 2 compares the Q300 against the NIST references and Table 3 compares results from the two solutions directly. Not surprisingly, the Q300 laboratory viscometer yielded results that are in line with referenced ASTM norms (0.44%) for variation. The portable Q3000 reported results were within its expected 3% specification, and the results from the Q3000 and the lab-based viscometer were also within 3% (Table 3). In the used oil comparison, Table 4 shows that results from the portable Q3000 were consistently within 3% of the bench-top Q300.

Figure 3 % difference between bench-top and portable equipment

The key question then is whether 3% is “good enough” in the context of the user’s specifications. As discussed earlier, used oil can present significant challenges for repeatability measurements, especially with oil, water, fuel and particle contamination — any of which can drive repeatability above 5% between tests of the same sample. OEM engine and rotating equipment providers and users consider viscosity variations greater than 10%, from nominal values, to be the first evidence of potential problems. A portable viscometer can detect such issues immediately allowing improved decision making and more efficient preventive maintenance.

Summary

With the advent of new solvent-free technology for field-based viscosity monitoring, a portable viscometer offers the performance necessary to detect variations of in-use oil to signal an impending problem at the equipment site.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.