This article covers the new capabilities of the Mastersizer 3000 from Malvern Panalytical and discusses the top 10 things to be considered when migrating from Malvern Panalytical’ Mastersizer 2000 to the new system.

Bench Space

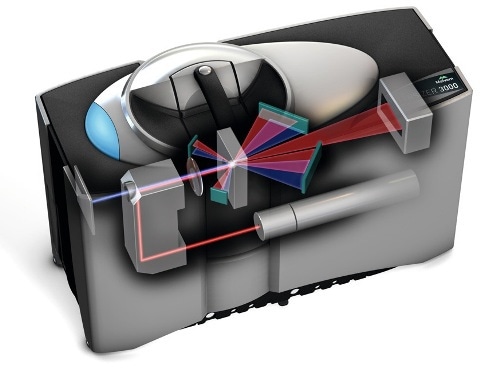

Figure 1. Mastersizer 2000 and Mastersizer 3000.

Laser diffraction has become the most commonly used technique for particle size analysis and bench space has become a significant factor as the method has migrated into standard laboratories. The new Mastersizer 3000 has a smaller footprint with lower weight and smaller size dispersers (Figure 1), thereby freeing up space for other key equipment.

Measurement Size Range

Purchasing equipment capable of operating over a broad particle sizing range can be advantages to any organization. The Mastersizer 3000 features a smaller detector that allows to measure an upper size limit of 3.5 mm, although its optical bench size is much smaller than that of the Mastersizer 2000. Moreover, the way of making measurements at different wavelengths is optimized in the new system.

Figure 2. Mastersizer 3000 offers better sensitivity in the size range of 10-1000 nm.

In the Mastersizer 3000, the red and blue light sources are introduced to the sample on exactly the same path (Figure 2), thereby enabling superior integration of the red and blue scattering data into one result and providing superior sensitivity in the size range of 10-1000 nm.

Sample Size

The selection of dispersions is based on the applications for which they are used. Dry dispersers such as Aero S or the Scirocco 2000 dispersers are required for some materials, while liquid dispersers such as the Hydro series of dispersion units are best suitable for other materials.

With improved dispersion efficiency and rapid data acquisition rate of 10,000 measurements a second, the Mastersizer 3000 can analyze samples in small quantities. Malvern Panalytical has demonstrated that its Aero S is capable of measuring sample as little as 5mg, with accurate dispersion pressure control for dispersion of friable materials like pharmaceutical actives or other organic compounds.

The Hydro LV offers similar functionalities to the Hydro 2000G for wet applications, enabling the measurement of larger samples of polydisperse materials. The Hydro MV is an alternative to the Hydro 2000S for smaller sample quantities, facilitating less consumption of high-cost organic dispersants and samples.

The chemically compatible liquid sample handling units of the Mastersizer 3000 help use a variety of dispersants. The Mastersizer 3000 is programmed for direct control of sample pumping/stirring, variable power in-line sonication, dispersant filling and system cleaning. The option for performing a syringe injection method using the wet measurement cell of the Mastersizer 3000 brings the total dispersant volume down to 10-15ml.

User-Friendly Software

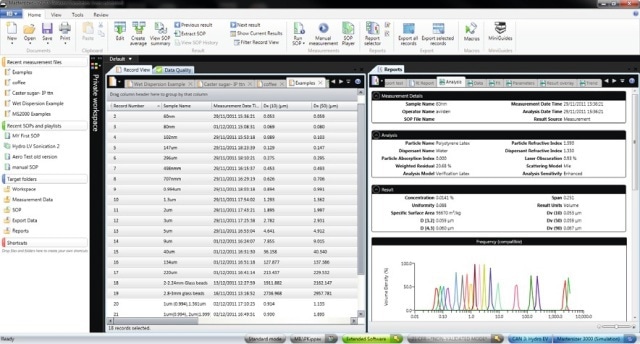

The Mastersizer 2000 has always been recognized for its software flexibility and user friendliness. Malvern Panalytical further developed this capability for its new Mastersizer 3000 using the latest Microsoft software development tools. The new Mastersizer 3000 software (Figure 3) has all the features of the Mastersizer 2000 software, such as records view, report views, SOPs and data export capabilities, but with easy accessibility and configurability.

Figure 3. The new Mastersizer 3000 software.

The new software has improved filtering and sorting features and can perform measurement comparison between various measurement files without making multiple copies of records.

Moreover, the new SOP comparison tool enables comparison of techniques used in generating results, thus facilitating detection of any method differences and troubleshooting of any problems with measurement reproducibility.

Process of Method Development

The Mastersizer 3000 measurement interface provides instant feedback on the measurement process, enabling users to easily trace the process of method development. A new measurement manager guides users through every step of the measurement process and provides direct access to all of the dispersion unit controls, thereby enabling users to understand the impact of changes in the dispersion conditions on measurements.

The addition of a live result trend view feature in the new Mastersizer 3000 provides current result, light scattering data, and a trend plot that shows the changes in the sample particle size during the measurement sequence, thereby enabling users to evaluate the stability of their measurements. Automatic statistics calculations (mean, max, min, standard deviation) help users to check whether the measurement repeatability is within acceptable limits.

Data Quality

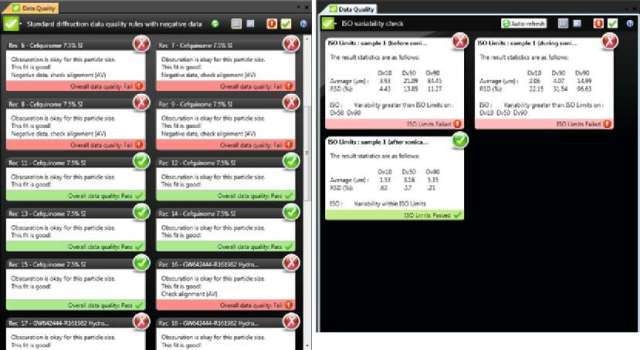

Figure 4. The new Mastersizer 3000 Data Quality tool.

The new Mastersizer 3000 Data Quality tool (Figure 4) helps users to identify the ways of optimizing measurements. After performing this task, the differences in the results can be verified, thereby ensuring that whether the results are in line with the reproducibility requirements mentioned in standards such as ISO13320:2009 and USP<429>. The option to integrate custom calculations facilitates users to perform calculation of their own quality parameters if required.

Easy Maintenance

Figure 5. The measurement cell of the Mastersizer 3000 system can be split with a simple flip of a lever.

Easy maintenance of the system between routine measurements becomes an important consideration, which has led Malvern Panalytical to design a new measurement cell for the Mastersizer 3000 system. The requirement for special tools and manual tightening of the measurement cell windows is eliminated in the new system. The measurement cell can be split with a simple flip of a lever (Figure 5), thereby providing faster and easier access to the inner cell window surfaces for cleaning and helping the system to work optimally.

The inclusion of a maintenance scheduling tool in the Mastersizer 3000 system enables users to set up reminders to perform simple preventative maintenance tasks and schedule yearly verification checks or routine service visits. Furthermore, the system features a new system health check tool that ensures the appropriate configuration and response of the system to software commands as designed.

Measurement Data Transfer

The Mastersizer 3000 has been designed with all the features that facilitate method transfer from the Mastersizer 2000. The Mastersizer 3000 software can open the Mastersizer 2000 record files. In addition, the results saved in the Mastersizer 3000 format measurement file (*.mmes) can be reanalyzed using all the standard analysis options available in the Mastersizer 2000 software. The Mastersizer 3000 software thus offers a long-term solution to users to access their archive of measurement results.

Transfer of Methods and Specifications

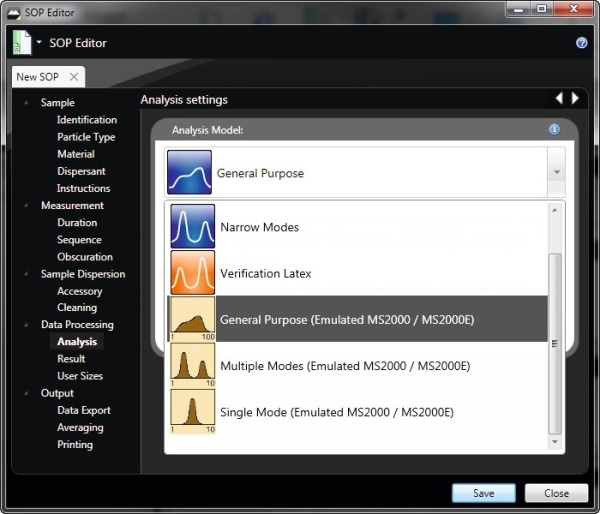

Figure 6. Mastersizer 2000 analysis mode.

The Mastersizer 3000 system has a broader measurement range when compared to the Mastersizer 2000. Furthermore, the measurement resolution is improved to below 1µm for both wet and dry measurements. To cover these situations, Malvern Panalytical has created a Mastersizer 2000 analysis mode (Figure 6) within the Mastersizer 3000 software to facilitate switching of the capabilities of the new system to be exactly like the Mastersizer 2000. This, in turn, helps achieve specification transfer more easily.

Support for Mastersizer 2000 System

Malvern Panalytical make provisions and planning to provide support for hardware, software and applications for up to seven years beyond the end of the production cycle of a product. Hence, there will be a considerable period to support both the Mastersizer 2000 and Mastersizer 3000 system.

Conclusion

The expected lifetime of the Mastersizer 3000 increases further into the future when compared to the Mastersizer 2000. This further facilitates the transfer to the new system. Malvern Panalytical also provides full planning and assistance to customers when change takes place.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.