The GX53 microscope was created for use in the steel, automotive, electronics, and other production industries. It produces clear pictures that can be challenging to obtain using traditional microscopy observation techniques.

The microscope speeds up the inspection process from observation to image processing and reporting when used in conjunction with PRECiV image analysis software.

Fast Inspections, Advanced Functionality

Analyze, measure, and quickly examine metallurgical structures.

Advanced Analysis Tools

- Easily create panoramas

- Capture both bright and dark areas

- Combined observation methods produce exceptional images

- Create all-in-focus images

Optimized for Material Science

- Industrial-standards compliant metallurgical analysis

- Software designed for materials science

User Friendly

Even amateur operators can prepare reports, examine data, and make observations with ease.

- User guidance helps simplify advanced analysis

- Efficient report generation

- Easily restore microscope settings

Advanced Imaging Technology

The validated optics and imaging technologies produce trustworthy solutions and clear images.

- Consistent color temperature: High-intensity white LED illumination

- Reliable optical performance: Wavefront aberration control

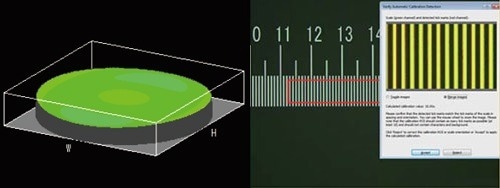

- Accurate measurements: Auto calibration

- Clear images: Image shading correction

Image Credit: Evident Corporation – Industrial Microscopy

Modular

Conveniently choose the parts the application requires.

- Users can create their own system: Fully adaptable system with a wide range of optional parts

Image Credit: Evident Corporation – Industrial Microscopy

Observation

Advanced Analysis Tools

Users can dependably identify flaws in the samples due to the clear, crisp images produced by the GX53 microscope's numerous observational capabilities. The additional lighting methods and image capture options in PRECiV image analysis software provide users with more alternatives for analyzing the samples and recording the findings.

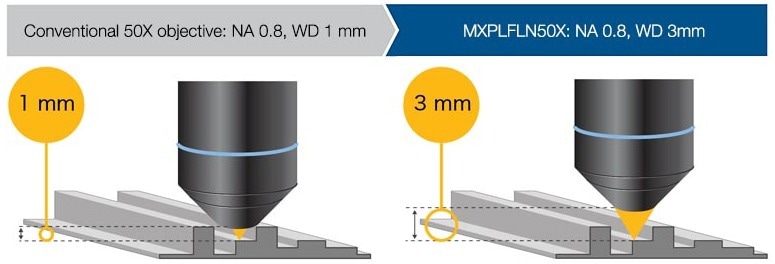

Combined High Numerical Aperture and Long Working Distance

The effectiveness of a microscope depends on its objective lenses. The new MXPLFLN objectives extend the capabilities of the MPLFLN series for epi-illumination imaging by optimizing both working distance and numerical aperture simultaneously.

Shorter working distances are often associated with higher resolutions at 20× and 50× magnifications, which necessitates retracting the sample or objective during the objective swap. The 3 mm working distance of the MXPLFLN series often solves this issue, allowing for quicker examinations with a reduced risk of the objective striking the sample.

Image Credit: Evident Corporation – Industrial Microscopy

Image Credit: Evident Corporation – Industrial Microscopy

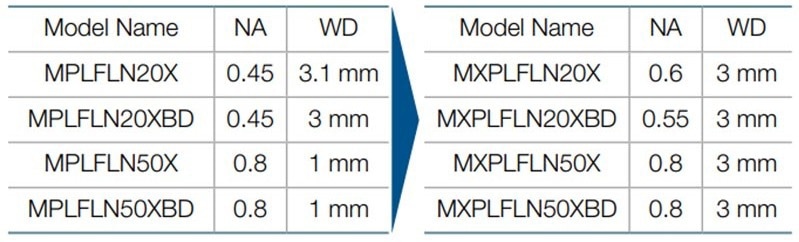

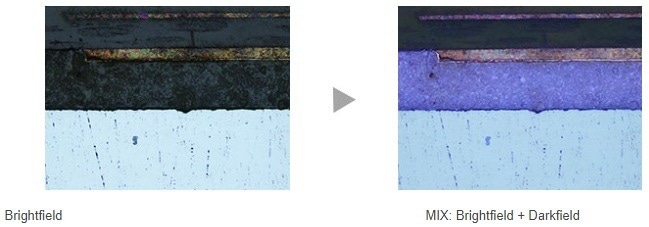

The Invisible Becomes Visible: MIX Technology

To see materials that are challenging to see with traditional microscopes, MIX technology combines darkfield with another observing technique, such as brightfield or polarization. The circular LED illuminator features a directed darkfield function that reduces sample halation to more clearly see surface roughness by lighting up one or more quadrants at once.

Cross-Section of a Printed Circuit Board

Image Credit: Evident Corporation – Industrial Microscopy

Stainless Steel

Image Credit: Evident Corporation – Industrial Microscopy

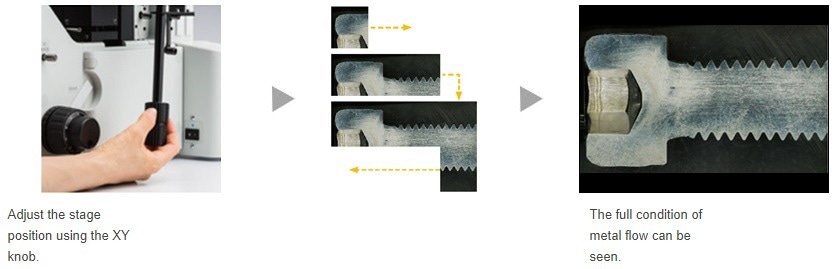

Easily Create Panoramic Images: Instant MIA

The XY knobs on the manual stage can be moved to stitch pictures together using multiple image alignment (MIA); a motorized stage is optional. PRECiV software creates panoramic images using pattern recognition, which makes it perfect for examining metal flow and carburizing conditions.

Metal Flow of a Bolt

Image Credit: Evident Corporation – Industrial Microscopy

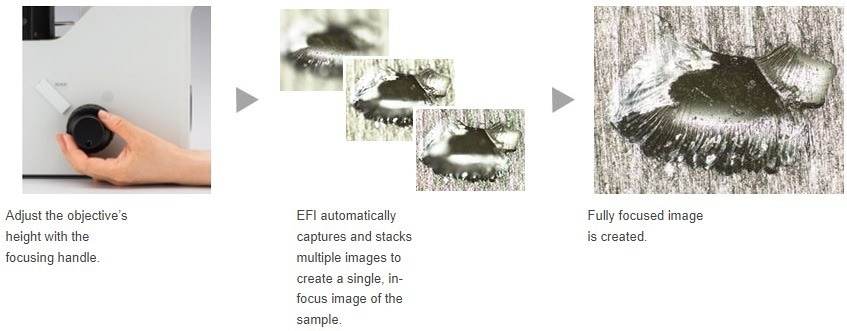

Create All-in-Focus Images: EFI

The extended focus imaging (EFI) feature of PRECiV software takes pictures of samples whose height rises over the depth of focus. To build a single, fully focused image of the sample, EFI blends these images. EFI generates fully-focused pictures even when examining a cross-section sample with an uneven surface.

EFI makes a height map to view structures using either a manual or motorized Z-axis.

Resin Parts

Image Credit: Evident Corporation – Industrial Microscopy

Capture Both Bright and Dark Areas Using HDR

High dynamic range (HDR) compensates for variations in brightness inside a picture to lessen glare using sophisticated image processing. Additionally, it enhances the contrast of low-contrast photos. HDR can be used to spot metallic grain boundaries and examine tiny features in electric devices.

Gold Plate

Image Credit: Evident Corporation – Industrial Microscopy

Chromium Diffusion Coating

Image Credit: Evident Corporation – Industrial Microscopy

Applications

These are but a few illustrations of what can be accomplished using various observational techniques.

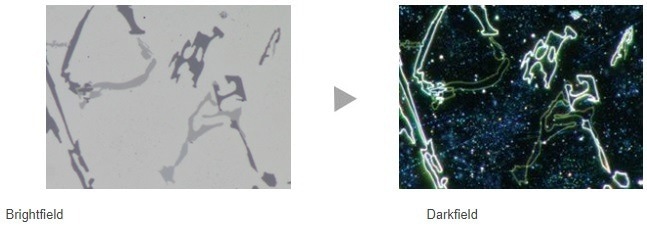

Polished Sample of Alsi (Brightfield/Darkfield)

Image Credit: Evident Corporation – Industrial Microscopy

Brightfield: A popular technique for observing reflected light from a sample involves shining a light directly at it. Darkfield: view light that has been scattered or diffracted by a sample, making faults such as minor scratches or blemishes show up clearly.

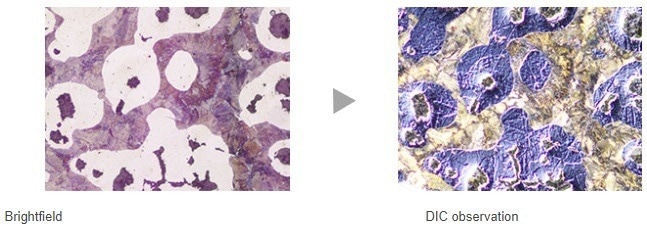

Spheroidal Graphite Cast Iron (Brightfield/DIC)

Image Credit: Evident Corporation – Industrial Microscopy

Differential interference contrast (DIC) is a method of observation where the height of a sample can be seen as a relief, like a 3D image with better contrast; it is perfect for inspecting materials with extremely small height changes, such as minerals and metallurgical structures.

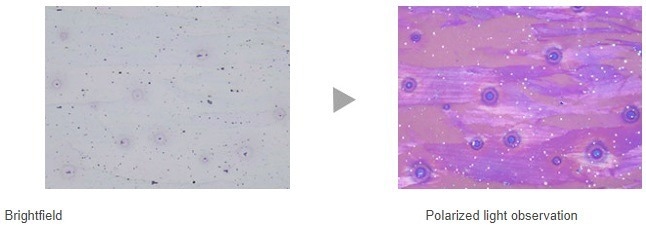

Aluminum Alloy (Brightfield/Polarized Light)

Image Credit: Evident Corporation – Industrial Microscopy

When viewing metallurgical structures, such as the graphite growth pattern on nodular cast iron and minerals, polarized light reveals a material’s texture and crystal state.

Electric Device (Brightfield/MIX Observation)

Image Credit: Evident Corporation – Industrial Microscopy

When viewing metallurgical structures, such as the graphite growth pattern on nodular cast iron and minerals, polarized light reveals a material’s texture and crystal state.

The above MIX observation image accurately depicts the color, texture, and state of the sticky layer of the device.

Specifications

Table 2. Source: Evident Corporation – Industrial Microscopy

| Optical systemOptical system |

UIS2 optical system (infinity-corrected) |

| Microscope frame |

Reflected light illumination |

Manual brightfield/darkfield selection by mirror unit

Manual field stop/aperture stop switch with centering

Light source: White LED (with Light Intensity Manager) /12 V, 100 W halogen lamp/100 W mercury lamp/light guide source

Observation mode: brightfield, darkfield, differential interface contrast (DIC)*1, simple polarizing*1, MIX observation (4 directional darkfield)*2

*1 Slider for exclusive use of this observation is required.

*2 MIX observation configuration is required. |

| Imprinting of scale |

All ports reversed positions (up/down) from observation positions seen through the eyepiece |

| Output front port (optional) |

Camera and DP system (reversed image, special camera adapter for GX) |

| Output side port (optional) |

Camera, DP system (upright image) |

| Electrical system |

Reflected light illumination

Built-in LED power supply for reflected light illumination

Continuously-variable light intensity dial

Input rating 5 V DC, 2.5 A (AC adapter 100–240 V, AC 0.4 A, 50 Hz/60 Hz)

Transmitted light illumination (requires the optional BX3M-PSLED power supply)

Continuously-variable light intensity dial by voltage

Input rating 5 V DC, 2.5 A (AC adapter 100–240 V, AC 0.4 A, 50 Hz/60 Hz)

External interface (requires the optional BX3M-CBFM control box)

Coded nosepiece connector × 1

MIX Slider (U-MIXR-2) connector × 1

Handset (BX3M-HS) connector × 1

Handset (U-HSEXP) connector × 1

RS-232C connector × 1, USB 2.0 connector × 1 |

| Focus |

Rack and pinion with roller guide

Manual, coarse and fine coaxial handle; focus stroke 9 mm (2 mm above and 7 mm below the stage surface)

Fine handle stroke per rotation: 100 µm (min. scale: 1 µm)

Coarse handle stroke per rotation: 7 mm

With torque adjustment ring for coarse focusing

With upper limit stopper for coarse focusing |

| Tubes |

Widefield (FN 22) |

Inverted: binocular (U-BI90, U-BI90CT), trinocular (U-TR30H-2), tilting binocular (U-TBI90) |

| Nosepiece |

Brightfield Holes: 4 to 7 pcs, Type: Manual/Coded, Centering: Enabled/Disabled

Brighfield/darkfield Hole: 5 to 6 pcs, Type: Manual/Coded, Centering: Enabled/Disabled |

| Stage |

Right handle stage for GX (X/Y stroke: 50 × 50 mm, max. load 5 kg)

Flexible right handle stage, left short handle stage (each X/Y stroke: 50 × 50 mm, max. load 1 kg)

Gliding stage (max. load 1 kg)

A set of teardrop and long hole types |

| Weight |

Approx. 25 kg (microscope frame 20 kg) |

| Environment |

- Indoor use

- Ambient temperature: 5 to 40 °C (45 to 100 °F)

- Maximum relative humidity: 80% for temperatures up to 31 °C (88 °F) (without condensation)

In case of over 31 °C (88 °F), the relative humidity is decreased linearly through 70% at 34 °C (93 °F), 60% at 37 °C (99 °F), and to 50% at 40 °C (104 °F).

- Pollution degree: 2 (in accordance with IEC60664-1)

- Installation/Overvoltage category: II (in accordance with IEC60664-1)

- Supply voltage fluctuation: ±10 %

|

GX41 Inverted Metallographic Microscope

Tilting Binocular Observation Tube

Metallic Structure (Brightfield)

Metallic Structure (Simple Polarization)

A 100W Fiber Light Source Combination