Users can easily follow instructions, read notes, and even watch movies without taking their eyes out of the eyepieces, thanks to the AR1 microscope system, which lets users superimpose text and digital pictures over the field of view of the microscope.

The AR1 module turns Evident/Olympus SZX stereo microscopes into augmented reality instruments so that users can carry out manufacturing operations and training sessions more quickly and effectively.

Faster, More Efficient Medical Device Manufacturing

Reduce the Risk of Human Error

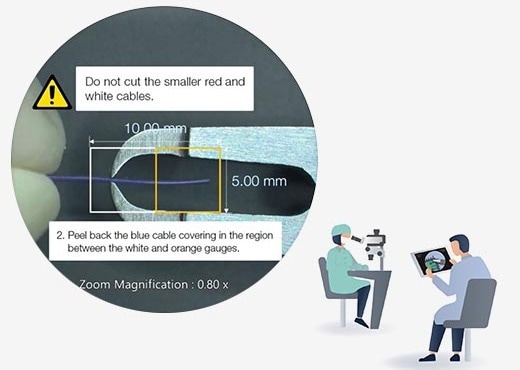

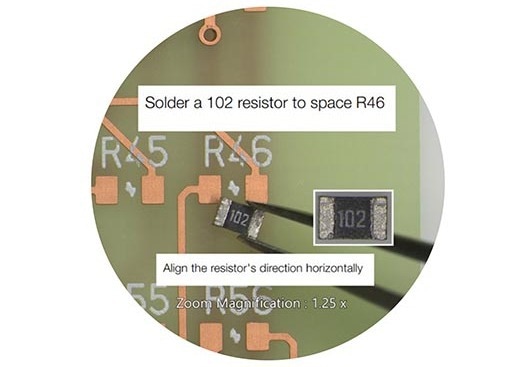

The AR1 microscope module’s capacity to project useful information into the microscope’s field of vision can assist assemblers to accomplish their work more accurately during challenging production tasks. Examples of this material include:

- Digital reticle

- Notes

- Images

- Zoom-linked measurement gauge

- Videos

This projection technology can minimize the occurrence of memorization errors and allow the operator to be more comfortable when working as they can stay focused on their task instead of having to repeatedly look away.

Image Credit: Evident Corporation – Industrial Microscopy

Keep the Manufacturing Line Moving

The system is simple to onboard and integrates into the manufacturing process due to the intuitive AR1 software, which makes it simple for production experts to swiftly set up the program that the operator will use throughout the assembly.

- Documentation is quick and easy because of the image and video recording features

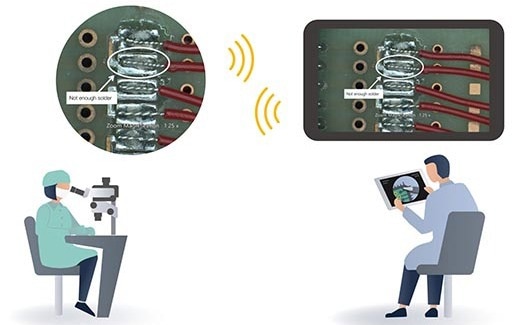

- Use third-party communication tools like Microsoft Teams to make it possible for a manager or engineer to supervise remotely by overssing the microscope’s field of vision

- Management working remotely can direct the assembler in real time to solve issues

Image Credit: Evident Corporation – Industrial Microscopy

Train New Manufacturing Employees Fast

Efficient Microscope-Based Assembly Training

Training is more effective and versatile with the AR1 system.

- A trainee can receive training while keeping an eye on the eyepieces, enabling them to stay focused

- An instructor is able to teach a new employee about each step of the assembly process and illustrate how components are intended to look when they are appropriately assembled

Image Credit: Evident Corporation – Industrial Microscopy

Training without Travel

The procedure will take longer and cost more money if trainers have to go to several places. Travel costs can be removed by the AR1 system, saving both time and money.

- Instead of having a live instructor to train new employees, use video recordings

- The ability to work remotely frees up travel time for trainers

Image Credit: Evident Corporation – Industrial Microscopy

Compatible with Existing Stereo Microscopes

Minimal Effort and Cost to Onboard

Most SZX stereo microscopes can be configured to work with the AR1 system. The tilting trinocular is swapped out for the SZX-AR1 module, which tightens right into the system.

Image Credit: Evident Corporation – Industrial Microscopy

Stay Comfortable While Working

For stereo microscopes, Evident provides a selection of ergonomic parts that let users work comfortably. Users can keep a relaxed, organic posture when using an Evident extensible eyepoint adjuster in conjunction with the ergonomic tilting trinocular of the AR1 device.

Image Credit: Evident Corporation – Industrial Microscopy

Key Features

Efficient Microscope-Based Production and Training

- The AR1 augmented reality microscope system increases user training effectiveness and production line efficiency.

Production Line

- On a PC with the AR1 software installed, generate an assembly manual using the program.

- Users can change the tilt angle from 5° to 45° and the eyepoint height within a 120 mm (4.7 inches) range, thanks to its ergonomic components.

- The assembly manual should be opened and projected onto the microscope’s range of view.

- Users can select a specific magnification without taking their eyes off the eyepieces since the zoom magnification sensor records the magnification. Using the buttons on the zoom magnification sensor or a third-party footswitch, users are able to navigate the projected instructions forward and backward while keeping their hands on the microscope.

- Maintain attention on the eyepieces during assembling to minimize eye movement and errors brought on by poor memorization.

- In the user's area of view, instructions are directly displayed. To explain what is observed or to request assistance from an offsite manager, users can add text, lines, arrows, and rectangles.

- Reduce the requirement for manual procedures by projecting a zoom-linked digital gauge, reticle, and grid in the field of vision.

- Take pictures and videos of the assembling process for analysis and documentation.

Training

- Ergonomic components help the user to work comfortably.

- A trainer can clearly demonstrate how a component is put together and emphasize the trainee’s work using a digital pointer that is in the field of vision.

- A remote communication platform, such as Microsoft Teams, can be used to link a trainer and trainee, eliminating the need for the trainer to travel.

- Self-training films should be projected into the trainee’s line of sight.

Specifications

Hardware

Table 1. Source: Evident Corporation – Industrial Microscopy

| . |

. |

| AR tilting trinocular tube SZX2-ARTTR |

Angle of observation tube: 5 to 45 degrees

Interpupillary distance adjustment range: 57 to 80 mm

Equipped with eyepiece clamping knob

Light-path switching mechanism: none

Eyepiece magnification: 1.25X; camera magnification: 1X

Functions of buttons on the front panel: AR image brightness adjustment (7 levels) and AR image ON/OFF

Input connectors: HDMI x 1, USB 2.0 (Type-C) x 1, DC jack x 1

Drive voltage: AC 100–240 V (AC adaptor)

Maximum power consumption: 10 W |

| Compatible stereo microscopes |

SZX–ZB7, SZX2–ZB10, SZX2–ZB16 |

| Zoom magnification sensor |

Main Functions:

(a) Set the zoom magnification (at click positions only)

(b) Move slides created on the software forward and backward

Output connector: USB 2.0 Type-C |

| Operating environment |

Ambient temperature: 10 °C to 35 °C (50 °F to 95 °F)

Relative humidity: 20 to 85%

Supply voltage fluctuation: ±10%

Pollution degree: 2 (in accordance with IEC60664-1)

Installation/overvoltage category: II (in accordance with IEC60664-1)

Stand tilt: ±3° or less |

| Conditions for safety standards |

Indoor use

Altitude: max. 2000 meters (6562 ft)

Temperature: 5 °C to 40 °C (41 °F to 104 °F)

Relative humidity: 20 to 80% (31 °C (87.8 °F) or less) (without condensation)

If over 31 °C (87.8 °F), the relative humidity in the operating environment must be decreased linearly to 70% at 34 °C (93.2 °F), 60% at 37 °C (98.6 °F), and 50% at 40 °C (104 °F) |

Software

Table 2. Source: Evident Corporation – Industrial Microscopy

| . |

. |

| Camera control function |

Exposure control: switching between auto and manual

ISO sensitivity adjustment: ISO100, 200, 400

White balance adjustment function: equipped (one-touch adjustment) |

| Acquisition function |

Snapshot acquisition

File saving formats: BMP, JPEG, PNG

Resolution: DP23: 3088 × 2076

DP28 :4104 × 2174

The camera image can be saved with the AR image simultaneously

Recording

File saving formats: mp4, mov; Video codec: H264

Audio format: MP3; Audio codec: mp3

Resolution: DP23: 1920 × 1080 (camera image range: 1600 × 1080)

DP28: 1920 × 1080 (camera image range: 1920 × 1080)

Video cannot be recorded out of the camera image range

The camera image can be saved with the AR image simultaneously

*The recording time is approximately one hour |

| Barcode function |

The SZX-AR1 software can generate a QR code linked to the procedure.

The QR code can be scanned with a barcode reader to recall the procedure in the eyepiece field of view.

Compatible barcode reader

COM communication is available.

A QR code can be loaded

Output barcode: QR code |

| Software language |

English, Japanese, Chinese, German, Spanish, Portuguese, and French |

PC Specifications:

- It is recommended that the PC used with this system complies with IEC/EN60950-1 or IEC/EN62368-1

- The PC’s system requirements are mentioned below; keep in mind that not all commercially available PCs will meet these requirements, even if the PC is used in the recommended operating environment.

Table 3. Source: Evident Corporation – Industrial Microscopy

| . |

. |

| OS |

Windows 10 Pro (64-bit), Windows 10 pro for Workstation (64-bit)

Windows 10 Version : 2004, 21H1

Windows 10 IoT Enterprise LTSC 2019 |

| OS language |

English, Japanese |

| Processor |

10th Gen Intel® Core™ i5 or later (or equivalent)

(Recommended core: 4 or more, clock frequency: 3.2 GHz) |

| Memory |

8 GB or more |

| Storage capacity to install software |

1 GB or more |

| Graphic controller |

Intel UHD Graphics 630 or higher |

| Monitor resolution |

1366 × 768 or higher |

| USB interface |

USB 2.0 Type-A x1 (for connecting to the AR tilting trinocular tube)

USB 2.0 Type-A x1 (for the zoom magnification sensor)

USB 3.1 Type-A x1 (for a DP23 and DP28 camera) |

| Monitor interface |

HDMI x1 (for connecting to the AR tilting trinocular tube)

HDMI 1.4 or more

HDMI connector: Type-A |