Evident has introduced a dedicated, turnkey solution called the EVIDENT CIX100 inspection system useful for manufacturers who maintain excellent quality standards in the cleanliness of manufactured components.

Manufacturers can rapidly obtain, process, and record technical cleanliness inspection data to conform to both company and international standards.

The intuitive software integrated into the inspection system guides users through every step of the procedure, which means cleanliness data can be achieved easily and rapidly even by novice operators.

EVIDENT CIX100 Turnkey Technical Cleanliness Inspection System: Simplify the Technical Cleanliness

The cleanliness of fluids, parts, and components forms the core of the manufacturing process. Fulfilling high standards for analyzing, counting, and categorizing the typical micron-sized foreign particles and contaminants is crucial for all procedures—that is, development, production, manufacturing, and quality control of the end product.

Both national and international directives explain the requirements of methodologies and documentation for establishing particle contamination on major machined components because such particles have a direct effect on the lifespan of components and parts.

Earlier, the residue was defined using the mass of residue particles. The standards being used today require more comprehensive data regarding the nature of the contamination, like the particle characteristic, particle size distribution, and the number of particles.

The EVIDENT CIX100 Cleanliness Inspection System has been developed to fulfill the cleanliness requirements of the contemporary industry as well as the international and national directives.

The technical cleanliness of components and parts is essential, especially in all manufacturing industries. Image Credit: Evident Corporation - Industrial Microscopy

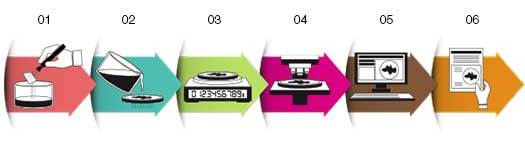

Standard process for cleanliness inspection: preparation (steps 1–3) and investigation (steps 4–6). (01: Extract, 02: Filter, 03: Weigh, 04: Inspect, 05: Review, 06: Results). Image Credit: Evident Corporation - Industrial Microscopy

Simple and Reliable

Flawlessly incorporated software and hardware result in a long-lasting, high-throughput system that provides precise and reliable data.

- Exceptional optical performance and reproducible imaging conditions

- Simple setup for true turnkey functionality

- Invariant system setup ensures precise repeatability and optimum security

- Complete system integration for high performance

- Proven durability by reproducible positioning and built-in calibration device

Image Credit: Evident Corporation - Industrial Microscopy

Intuitive Guidance for Maximum Productivity

User-friendly, dedicated workflows reduce user action and offer consistent data—regardless of operators and their experience level. Inspection data can be easily revised through user-friendly tools.

- Includes touch screen support for efficient handling

- Step-by-step guidance to enhance productivity and decrease the time taken for inspection and process steps

- User right management to limit functionality and prevent operator handling mistakes by limiting functionality

- Data management is ensured through automated result storing and sharing options

- Compliant One-Click Reporting for instant documentation

Image Credit: Evident Corporation - Industrial Microscopy

Fast Live Analysis

The novel, all-in-one scan solution allows scans with classification in non-reflective and reflective (metallic) particles to be finished at double the speed of other inspection systems. Instant feedback of sorted and counted particles helps users make quick decisions.

Image Credit: Evident Corporation - Industrial Microscopy

- Automatic live processing and categorization of contaminant particles varying from 2.5 µm up to 42 mm in size

- Overview image for direct detection of particle clustering, filter coverage, or worst particles

- Live analytics and result display for the shortest reaction time

- Exclusive all-in-one scan technology ensures high throughput by detecting both non-reflective and reflective objects in a single scan

- Height measurement support is available as an option

- Compliant results through the support of international standards

Efficient Data Evaluation

User-friendly and robust tools help revise inspection data. High flexibility is ensured through the support of all international standards. All relevant inspection results are clearly represented with maximum time savings.

Image Credit: Evident Corporation - Industrial Microscopy

- Different particle views can be visualized for instant identification

- Images and data are clearly arranged for efficient data review

- Inspection data can be easily reclassified, reviewed, revised, and recalculated

- Proven capability as thumbnails and particle location are connected to their dimensional images

- Trend analysis to detect deviation of potential measurements over time

- Short reaction time, thanks to the live display of overall cleanliness code, particle and classification tables

- Complete control by displaying comprehensive inspection data set in a single view

Compliant Report Creation

One-click reporting fulfills the methodologies and requirements stipulated in international standards. Report customization (for example, particle morphology) makes it easy to fulfill company standards.

Image Credit: Evident Corporation - Industrial Microscopy

- Customizable templates ensure smart variability

- Fully intuitive and professional documentation on the basis of compliant templates

- Advanced data storage options for long-term result justification

- Time-optimized and efficient exchange through direct file sharing options

- Numerous output formats support excellent flexibility