Evident’ OLS5000 laser confocal microscope accurately quantifies surface roughness and shape at the submicron level.

The OLS5000 offers four times faster data acquisition compared to the earlier model from Evident, thus considerably increasing productivity.

1. Precise imaging

The OLS5000 has the capability to capture the shape of any surface.

Image Credit: Evident Corporation – Industrial Microscopy

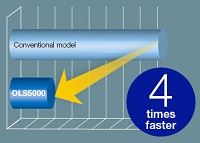

2. Fast

Users can obtain reliable data four times quicker compared to the earlier model.

Image Credit: Evident Corporation – Industrial Microscopy

3. Easy to operate

Users can just place their samples and press the start button.

Image Credit: Evident Corporation – Industrial Microscopy

4. Longer working distance for larger samples

Users can measure samples with a height of up to 210 mm.

Image Credit: Evident Corporation – Industrial Microscopy

Applications

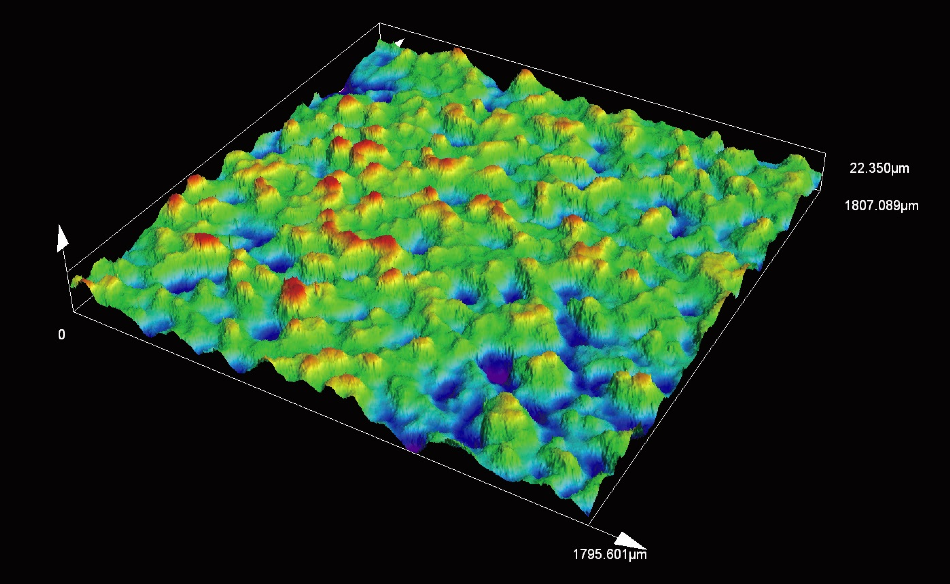

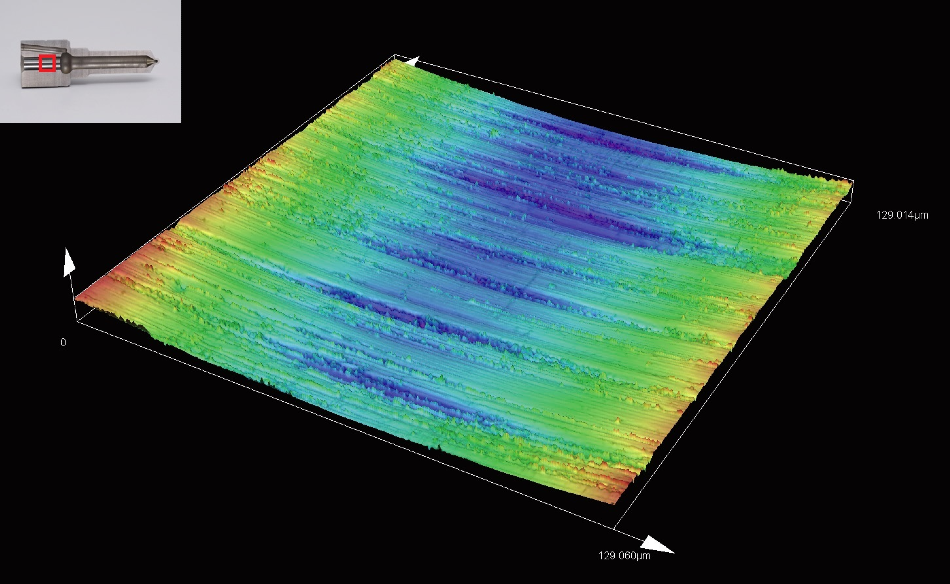

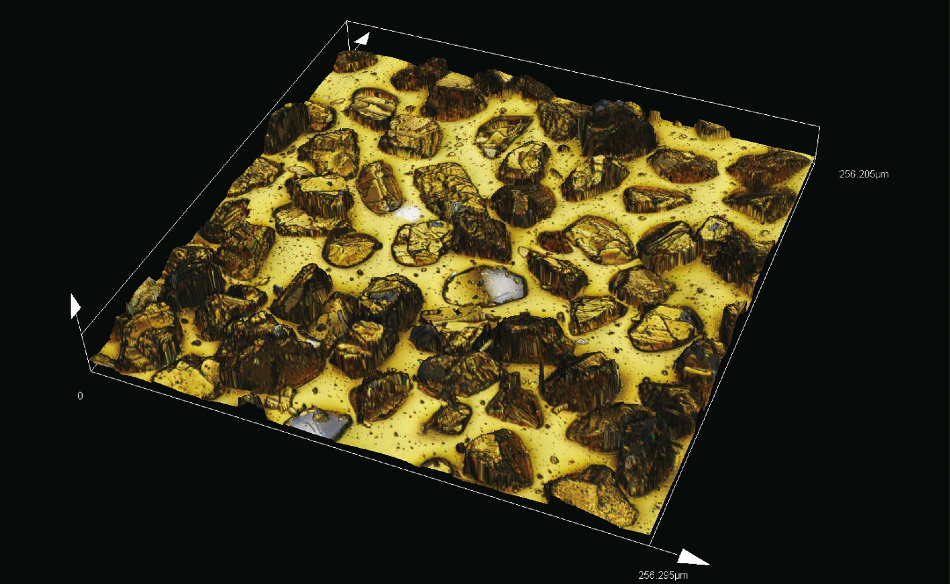

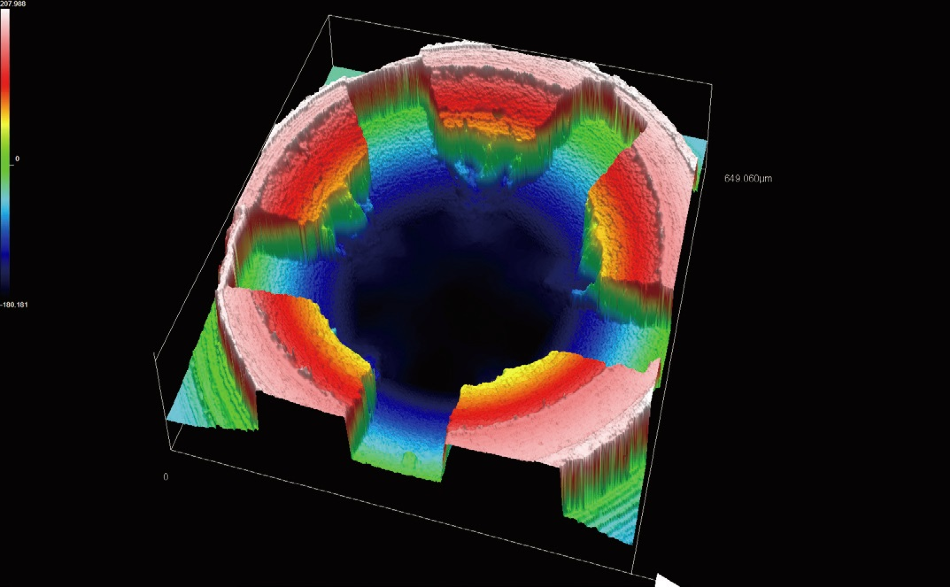

Automotive/Metal Processing

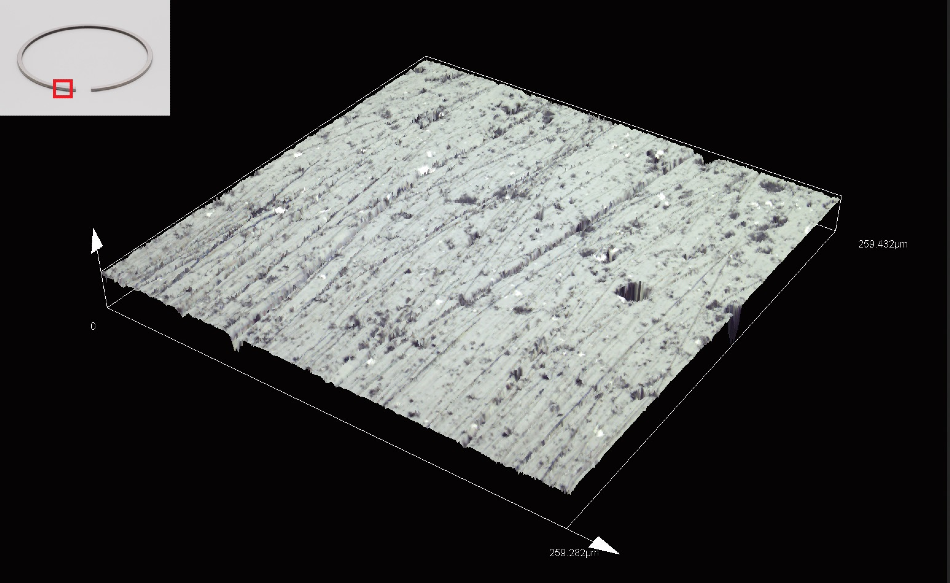

Inner texture/area roughness measurement (MPLAPON20XLEXT / 3 x 3 stitched). Image Credit: Evident Corporation – Industrial Microscopy

Fuel injector nozzle (replica)/area roughness measurement (LMPLFLN50XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Piston ring/area roughness measurement (MPLAPON50XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

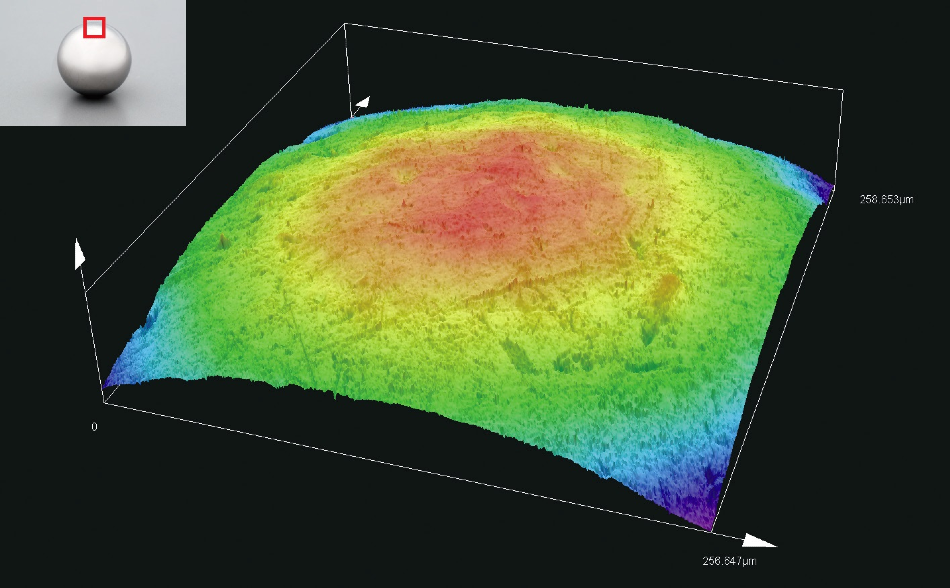

Bearing ball/profile measurement (MPLAPO50XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Materials

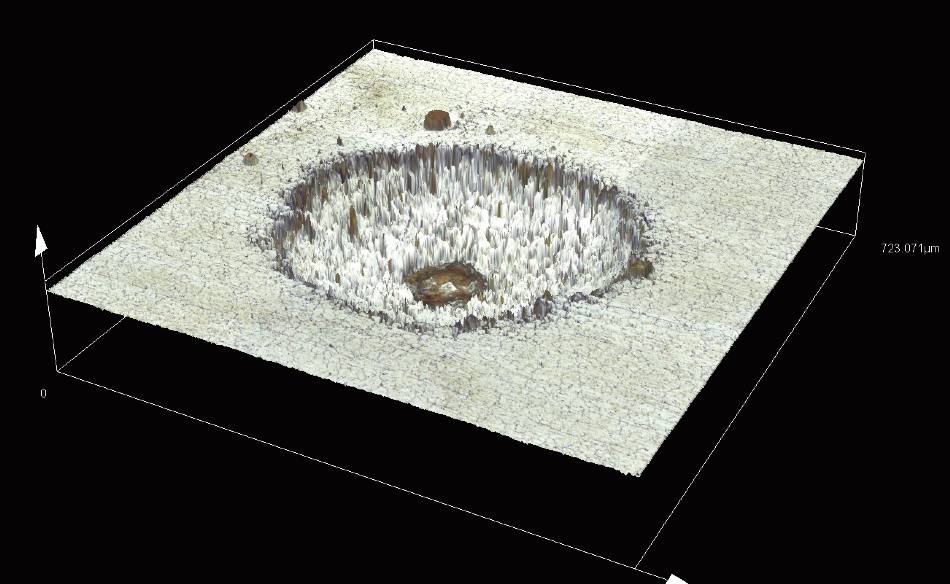

Corrosion on stainless steel/height measurement (MPLAPON20XLEXT / 3 x 3 stitched). Image Credit: Evident Corporation – Industrial Microscopy

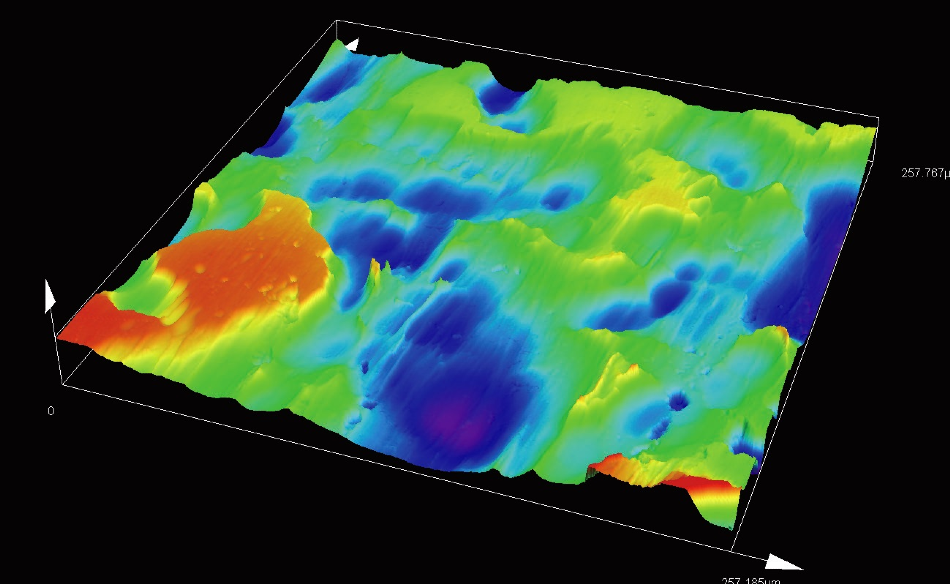

Copper plate/area roughness measurement (MPLAPON50XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Diffusion plate/profile measurement (MPLAPON50XLEXT / 3 x 3 stitched). Image Credit: Evident Corporation – Industrial Microscopy

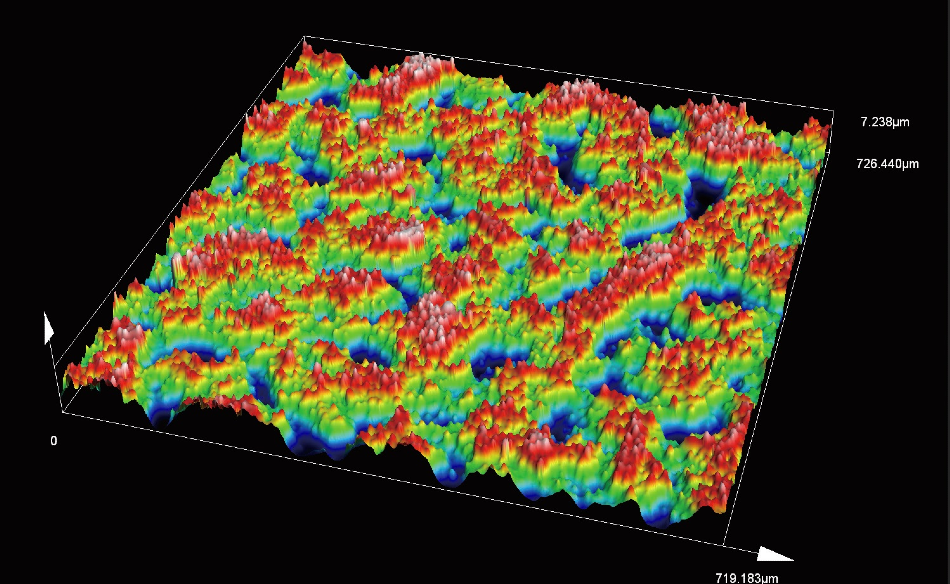

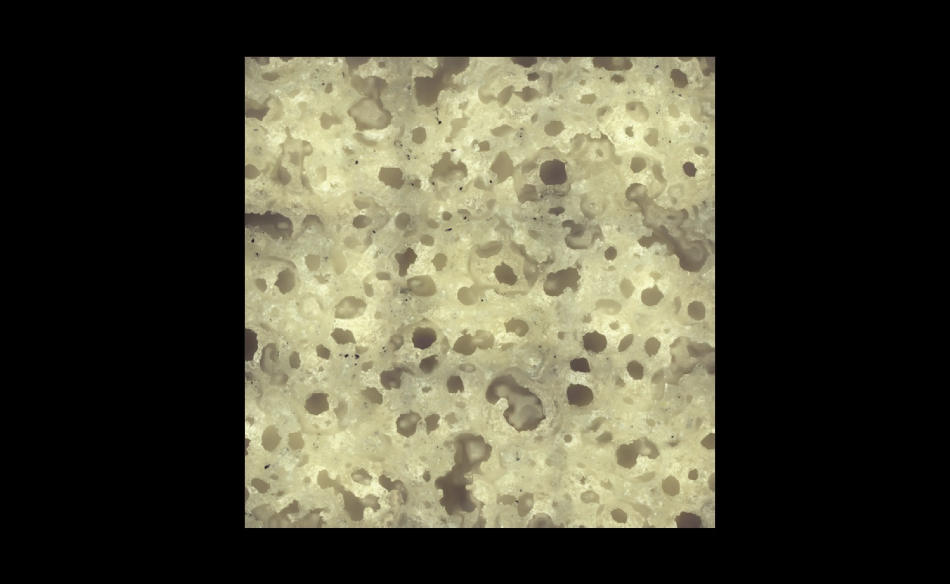

Sponge/profile measurement (MPLAPON20XLEXT / 3 x 3 stitched). Image Credit: Evident Corporation – Industrial Microscopy

Electronic Components

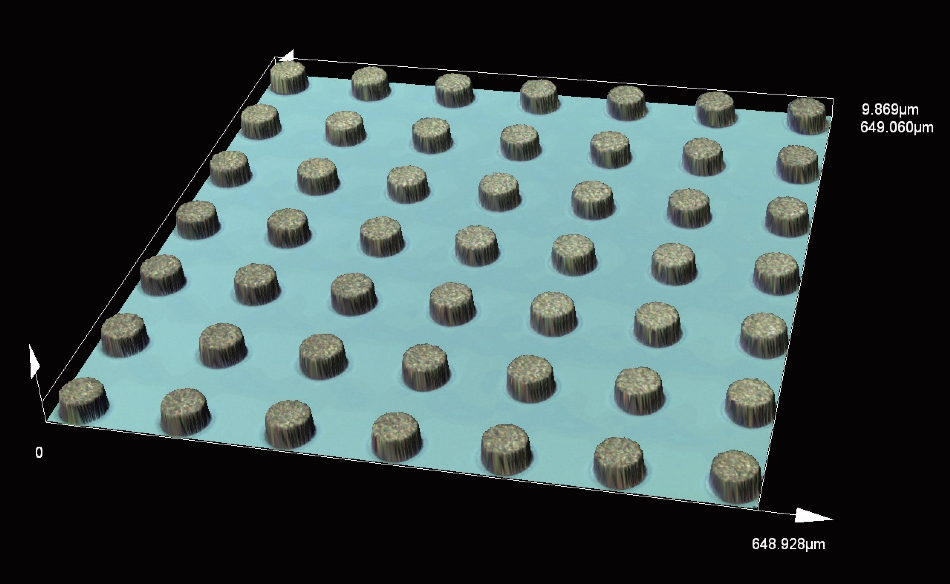

Ni bump/height measurement (MPLAPON20XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

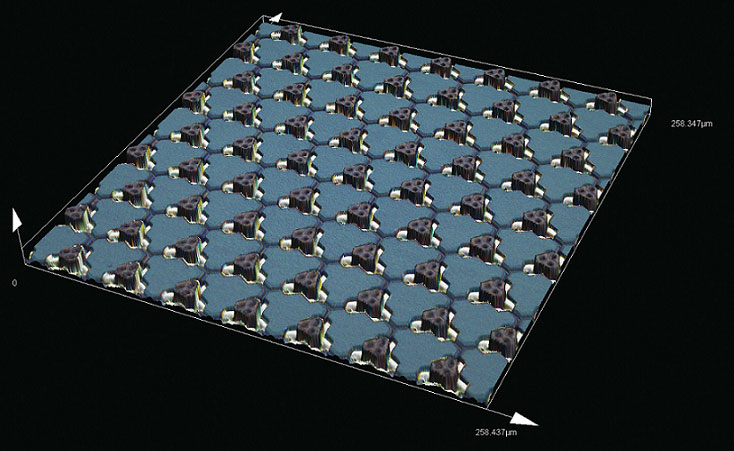

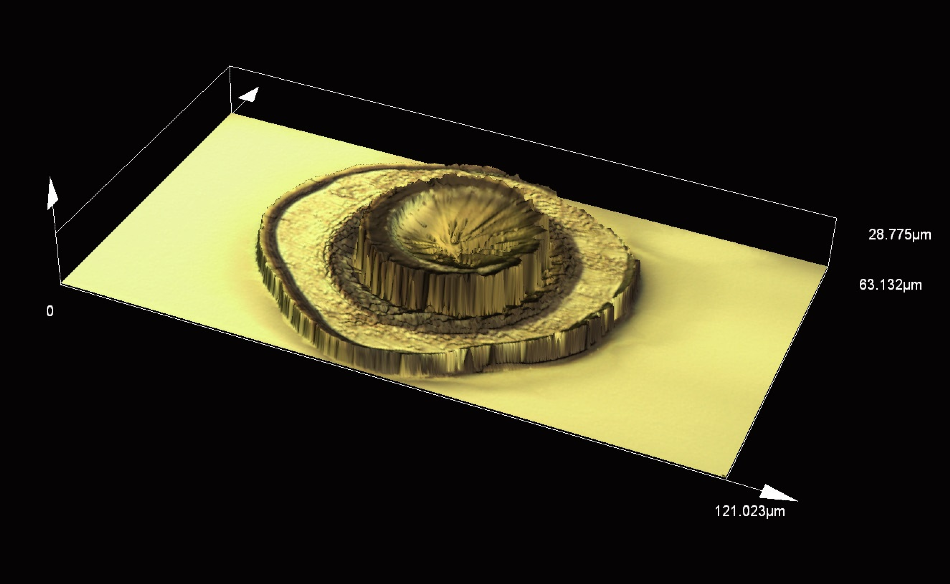

MEMS ultrasonic transducer (MPLAPON50XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

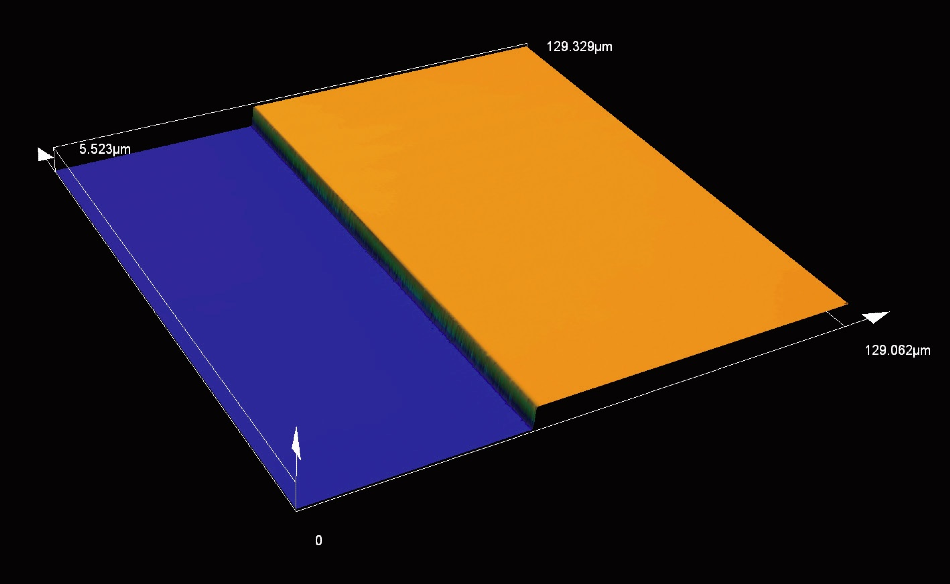

Photoresist/height measurement (MPLAPON100XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Bonding wire (MPLAPON100XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Others

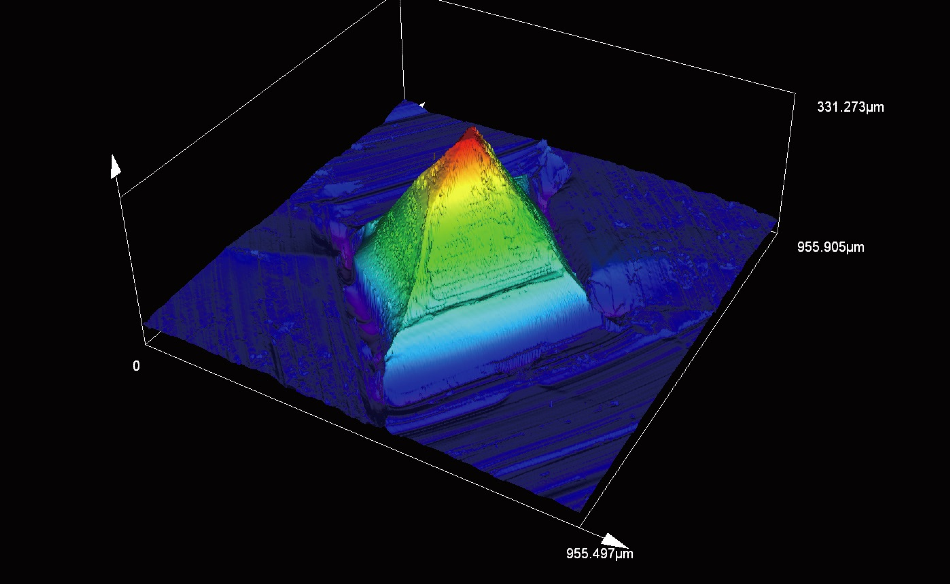

Micro needle/profile measurement (MPLAPON50XLEXT / 6 x 6 stitched). Image Credit: Evident Corporation – Industrial Microscopy

Skin (replica)/area roughness measurement (MPLAPON20XLEXT / 5 x 5 stitched). Image Credit: Courtesy of Functional Design Laboratory, Faculty of Fashion Science, Bunka Gakuen University

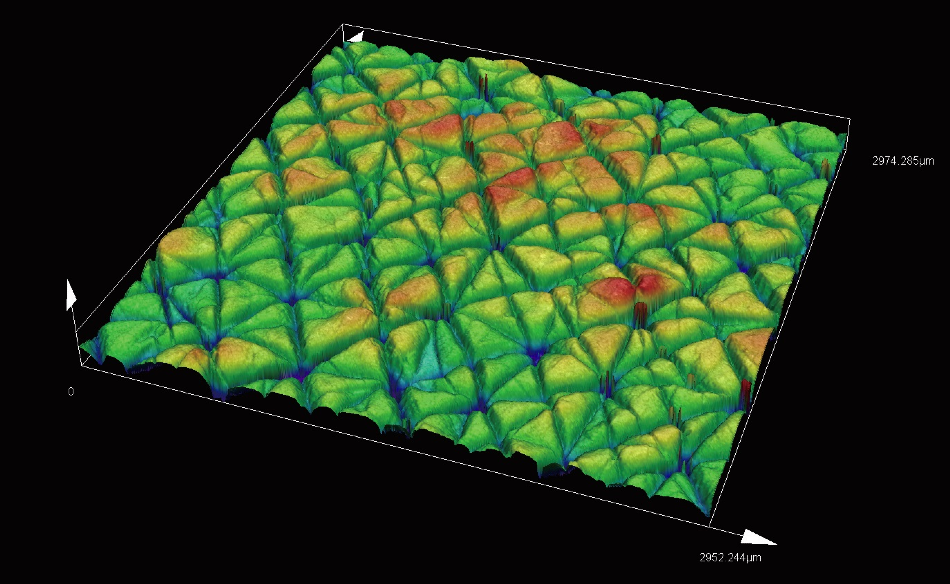

Grind stone/profile measurement (MPLAPON20XLEXT). Image Credit: Evident Corporation – Industrial Microscopy

Acceptance seat of ballpoint pen/area roughness measurement (LMPLFLN20XLEXT). Image Credit: Evident Corporation – Industrial Microscopy