The MiniFlex X-Ray Diffractometer (XRD) is a powerful instrument for the quantitative and qualitative analysis of polycrystalline materials. With its various range of functions, including phase identification and quantification, determination of percent crystallinity, crystallite size and strain and lattice parameter, and Rietveld refinement; the device serves as a useful tool in a wide range of industries, including research, chemistry, quality control, and material science.

The MiniFlex XRD model is the newest addition to the MiniFlex series from Rigaku, following previous models of the MiniFlex system that was launched decades ago.

Speed and Sensitivity through an Advanced HPAD Detector

The MiniFlex XRD system promises efficiency and usability through its innovative construction and operational features. Speed and sensitivity are maintained through a HyPix-400 MF 2D Hybrid Pixel Array Detector (HPAD) coupled with a 600 W X-ray source and a new 8-position automatic sample changer. These prominent features would enable users to operate the MiniFlex in various modes using a wide range of samples.

In addition, a variety of X-ray tube anodes, coupled with a range of sample rotation and positioning accessories and temperature attachments, could be used to ensure versatility in performing qualitative and qualitative analysis of a variety of samples for routine quality control or research purposes. The sixth-generation MiniFlex XRD system embodies the Rigaku philosophy of ‘Leading with Innovation’ by offering the world’s most advanced benchtop XRD.

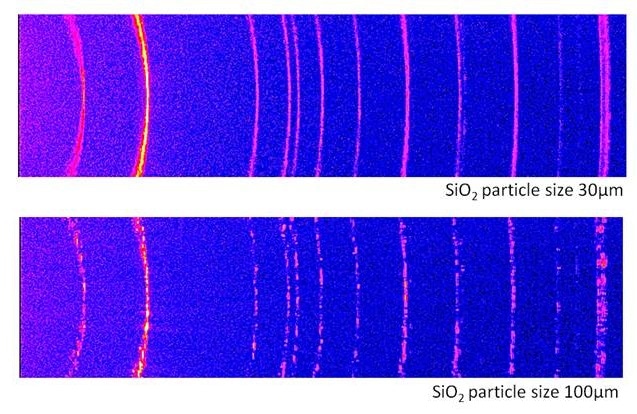

Data example from HyPix-400 MF detector

Extended Functions

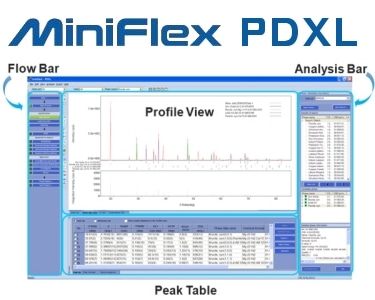

Each MiniFlex XRD system comes with the latest version of PDXL, Rigaku's full-function powder diffraction analysis package. The PDXL package would enable users to use a fundamental parameter method for more accurate peak calculation and phase identification using the Crystallography Open Database (COD) and a wizard for ab inito crystal structure analysis.

Safe and Easy-To-Use

With its sixth generation design, the MiniFlex XRD system maintains usability through a simple yet powerful design. Its compact, fail-safe radiation enclosure and incident beam variable slit are designed to ensure safety during operations. Additionally, the MiniFlex XRD system allows manual or computer-generated processes, extending its use and applicability to more areas.

MiniFlex XRD History

Originally introduced in 1973, the Rigaku MiniFlex XRD was the first commercial benchtop XRD instrument. The MiniFlex was about one-tenth of the current size and was dramatically less expensive than conventional XRD equipment during that period.

The first and second-generation utilized a horizontal goniometer, with data output provided by an internal strip chart recorder. The third-generation model, introduced in 1995 and was called Miniflex+, provided an increased power to 450 watts and allowed for Windows PC control.

Starting from the Miniflex+, the next generations of the Rigaku MiniFlex series utilized a vertical goniometer and an automatic sample changer. Introduced in 2006, the fourth generation offered a monochromatic X-ray source and a D/teX Ultra 1D silicon strip detector. Meanwhile, the fifth-generation system, introduced in 2012, promoted a stunning feature of 600 W of available power and new PDXL powder diffraction software.

New 6th generation MiniFlex benchtop X-ray diffractometer from Rigaku