With a maximum stroke of ±50 mm and maximum velocity of 2 m/s, high-speed repeated load tests can be conducted using quiet and clean electromagnetic force as the driving power, with no use of oil. The test space is huge, therefore, environmental tests could be conducted with the constant temperature tank (option).

Features

Fatigue and endurance testing machine with direct electrically powered actuator

Quick, large movements

- Capable of sine wave cycle testing at speeds up to 2 m/s

- Offers stroke lengths up to ±50 mm

- Allows ±20 µm displacement amplitude at 200 Hz frequencies.

Image credit: Shimadzu Scientific Instruments

Highly accurate control and measurement, excellent operability

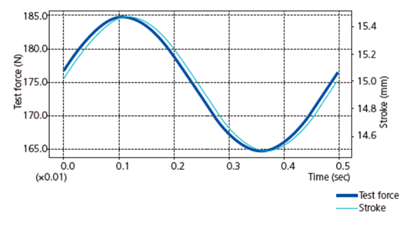

Allows 24-bit rangeless, high-resolution test force measurement and control, offers full digital control for autotuning control parameters and waveform correction, and allows performing offset load tests with high precision. The system also includes a specialized interactive controller that interacts via a color LCD screen and touch panel.

High rigidity frame

A very rigid loading frame that is resistant to resonance is used.

Electromagnetic actuator

The actuator is coupled with low-friction bearings to achieve high waveform repeatability.

Dual-stage crosshead drive mechanism

Using two buttons to operate the crosshead and clamps helps prevent operating errors and accidents.

Large testing table

Allows testing of large samples; lifting/lowering the crosshead can provide a testing space large enough to install a thermostatic chamber.

Controller/software

The controller allows high-performance and high-functionality dynamic and fatigue testing.

Eco-friendly

Actuating the system directly with electricity makes it highly efficient. In addition, the system generates no waste oil, which can have a large environmental load.