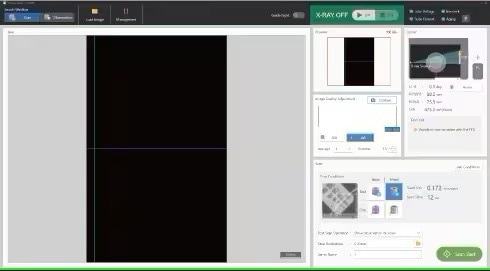

The XSeeker 8000 is a compact benchtop X-Ray computed tomography (CT) system. Its intuitive software suite allows the user to quickly acquire advanced three-dimensional images in as fast as 12 seconds. This system proves exceptionally valuable for defect inspection and dimensional analysis of materials such as resins, plastics, and die-cast parts.

Features

Compact benchtop CT sytsem

Smallest bench-top CT system in its class

The XSeeker 8000 is the smallest system in this X-Ray output class. This enables installation in a wide array of locations.

Image Credit: Shimadzu Scientific Instruments

Powerful image processing, including STL conversion

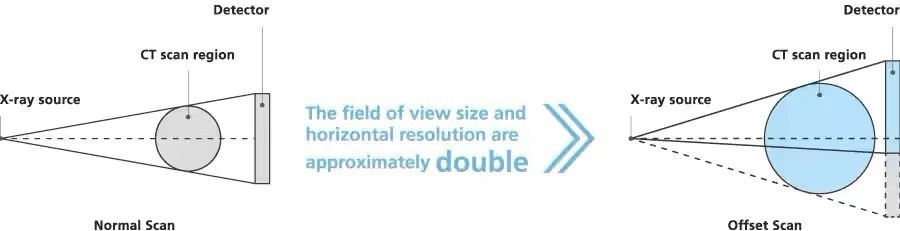

High-accuracy offset scan mode

Thanks to its innovative offset scanning methods, the XSeeker can accommodate samples with a maximum diameter of 12 inches and a height of up to 13 inches. This approach grants a generous 4-inch diameter field of view.

Image Credit: Shimadzu Scientific Instruments

Equipped with a 50 μm pixel pitch flat panel detector

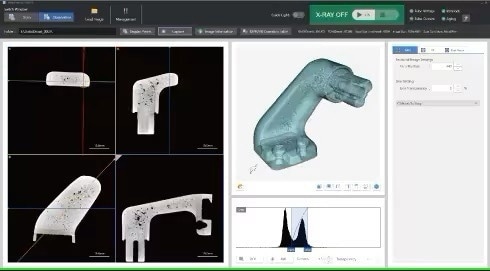

The system is fitted with a versatile viewer with multiple functions. Beyond the Multi-Planar Reconstruction (MPR) display, which presents multiple cross-sectional images in parallel, this can be seamlessly integrated with a Volume Rendering (VR) display that enables three-dimensional presentations, enhancing the overall observational experience for more intuitive observations.

Measurement can be done on both VR and cross-sectional images. The CT information can be transformed into a mesh file (STL) for use in 3D printers or modeling analysis.

Image Credit: Shimadzu Scientific Instruments

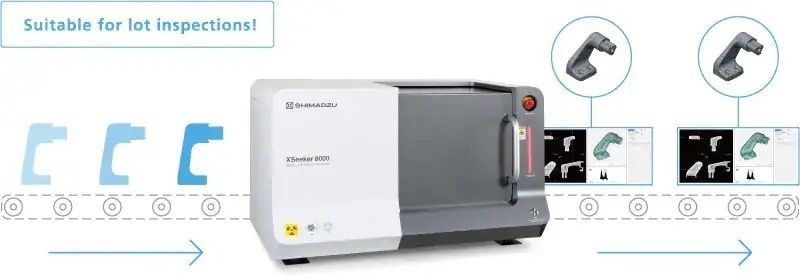

Optimized for high-throughput inspection

Simple 3-step operation

Starting observations are enabled via a simple 3-step process. After installation, new operators are able to easily operate the system with minimal training. Calibration is not needed before sample placement.

Image Credit: Shimadzu Scientific Instruments

Operation at the push of a button

Operation at the push of a button improves throughput in inspection applications using recurrent scanning of samples with the same shape.

The ideal conditions, which include the position displayed and the contrast at the time of observations, are recorded along with the scanning conditions. This means that observations can start immediately after scanning without adjusting the contrast or observation position. All operations, from starting the scanning to observing the results, can be completed at the push of a button without any software operations.

Image Credit: Shimadzu Scientific Instruments

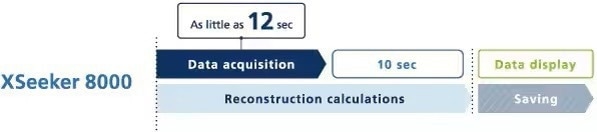

Scanning in as little as 12 seconds and high-speed reconstruction calculations

High-speed scanning can take as little as 12 seconds. In addition, the system is fitted with the same reconstruction system as high-end models. Therefore, CT data can be displayed in as little as 10 seconds after scanning is complete. This is almost twice as fast as Shimadzu’s other CT models.

Image Credit: Shimadzu Scientific Instruments

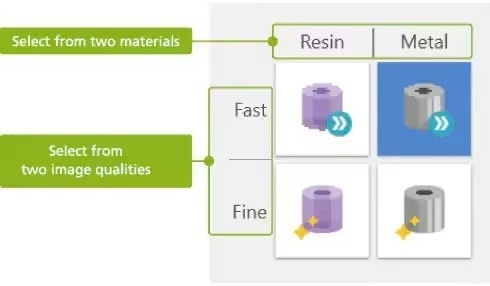

Recommend scanning function

The system is fitted with a recommended scanning function, which means that all the scanning conditions can be set using one click. The optimal imaging conditions can be set easily just by selecting one combination of material and image quality.

Image Credit: Shimadzu Scientific Instruments

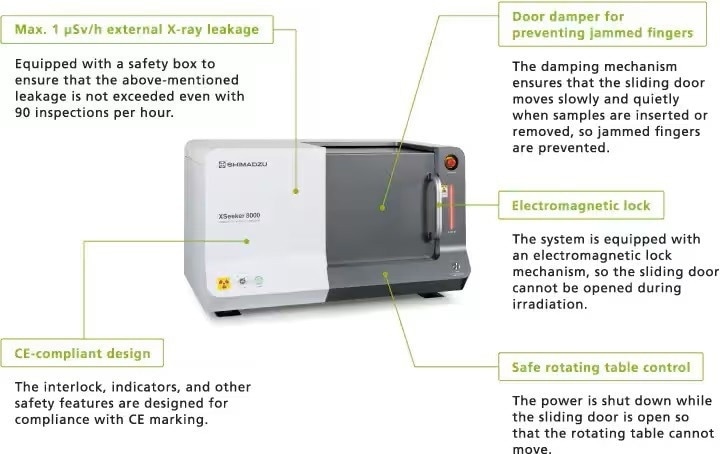

Designed with safety in mind

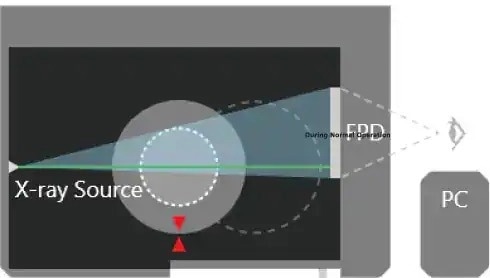

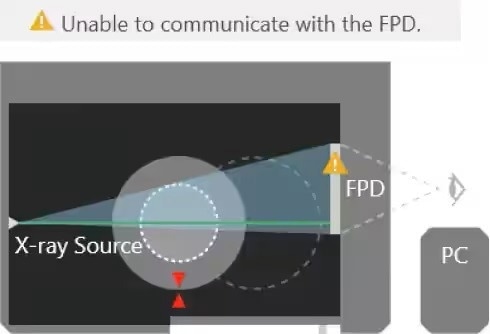

Status monitor

Besides showing the instrument status, along with the stage position at the time of normal operation, the monitor will display information about any errors that happen at the time of abnormal functioning and the site where the problem happens so the operator is notified of the problem immediately.

From warnings that the sliding door is not closed, for example, to alarms signaling communications faults and overheating of the X-Ray generator, the system’s status as a whole is constantly monitored.

During normal operation. Image Credit: Shimadzu Scientific Instruments

During abnormal operation. Image Credit: Shimadzu Scientific Instruments

Safety compliant with CE marking

Image Credit: Shimadzu Scientific Instruments

Analysis of thick samples with ease

Image quality and functionality on par with high-end models

Image Credit: Shimadzu Scientific Instruments

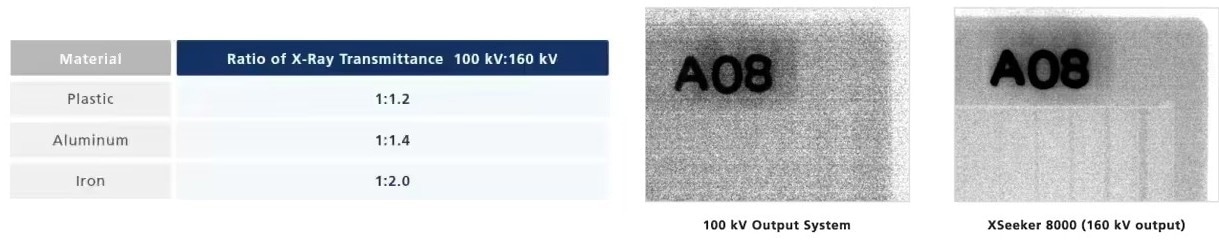

High 160 kV output achieves high penetration ability

Due to its 160 kV X-Ray output, the system can observe thick, difficult-to-penetrate plastic and metal parts.

Note: The following are reference values.

Advanced built-in post-processing software

The system is fitted with a high-functionality, all-inclusive display, facilitating concurrent observations of 3D computed tomography (CT) images and 2D/3D multiplanar reconstruction (MPR). High-speed reconstruction software enables CT data to be shown just 10 seconds after scanning is complete.

Scanning window. Image Credit: Shimadzu Scientific Instruments

Operation window. Image Credit: Shimadzu Scientific Instruments