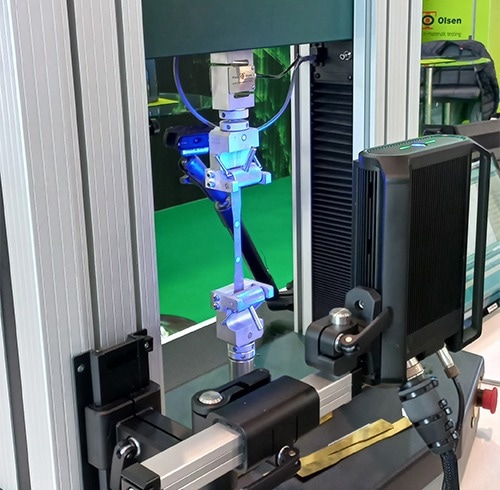

Tinius Olsen unveils Vector, a groundbreaking advancement in extensometer technology set to replace multiple sensors—both contacting and non-contacting—with a single, industry-tailored instrument.

By fusing adaptive AI capabilities with optical hardware, Vector automates the strain-capturing process and improves operator safety, measurement accuracy, and data consistency while lowering test throughput times and complexity.

Features and Benefits

- Non contacting with digital placement of specimen gage marks supporting an automated process.

- 0.5 μm resolution (1.9685039e-5 inch), capable of ASTM E83 Class B1 and ISO 9513 Class 0.5.

- Various marking options are available, depending on the material. These options include rings and speckles.

- Output data available in analog formats.

Image Credit: Tinius Olsen

Specifications

Field of View: 70 H × 25 W × 40 D [mm] fixed Cuboid

Real-Time Data Rate: ≤ 150 Hz, platform dependent. Full system from acquisition to output

Strain Outputs: Analog Output: ±10 V, short-protected, selectable units and range; includes 3 m (10 ft) shielded output cable

Resolution: <0.5 μm quasistatic and cyclic; Typical RMS resolution at typical settings. Resolution is a function of the marking data rate and filter settings

Extensometer Accuracy Class: ISO 9513 Class 0,5 and ASTM E83 Class B-1 capable

Image Credit: Tinius Olsen