Dec 7 2007

Let’s say a fuel derived from biomass produces too much soot when it’s burned in a combustion chamber designed for fossil fuels.

How can an engineer find the source of the problem? It originates, after all, in the flame zone of a highly turbulent combustion chamber. That’s not exactly an easy place for an engineer to take measurements.

“It’s fairly obvious when a combustor is not running well and producing a lot of soot and other pollutants,” said Terry Meyer, an assistant professor of mechanical engineering at Iowa State University. “But then how do you solve that problem? To do that we can open up the black box and look inside the combustion chamber itself.”

The tools that Meyer is developing to do that are highly sophisticated laser-based sensors that can capture images at thousands and even millions of frames per second. Those images record all kinds of data about what’s happening in the flaming mix of fuel and air.

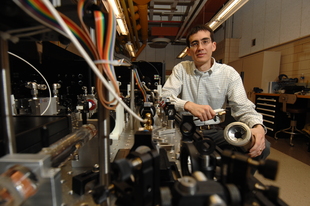

Terry Meyer is building the high-speed laser system in the foreground to analyze the performance of combustion systems and components such as the parts he is holding.

Terry Meyer is building the high-speed laser system in the foreground to analyze the performance of combustion systems and components such as the parts he is holding.

“The goal is to probe this harsh environment to provide the knowledge required to reduce pollutant emissions and enable the utilization of alternative fuels,” Meyer said.

By selecting lasers of different wavelengths, Meyer’s combustion sensors can record where pollutants such as soot, nitric oxide and carbon monoxide are being formed. The sensors can also look for unburned fuel and capture data about fuel sprays, fuel-air mixing and energy release.

Meyer’s lab is now working on a two-year project to develop and advance laser techniques that are expected to help engineers improve the combustion systems that move vehicles, produce power and heat buildings. An important goal of the project is to analyze and improve the performance of alternative fuels in modern combustion systems.

Meyer’s research is supported by an $87,000 grant from the Grow Iowa Values Fund, a state economic development program. This grant is supplemented by a contribution of products and engineering expertise from Goodrich Corporation’s Engine Components unit in West Des Moines, a producer of fuel system components for aircraft engines, auxiliary power units, power-generating turbines and home heating systems. ConocoPhillips, the third largest integrated energy company in the United States, is supporting similar projects in Meyer’s lab. The projects are part of ConocoPhillips’ eight-year, $22.5 million research program at Iowa State. Meyer’s research is also drawing interest and support from sources such at the National Aeronautics and Space Administration and the U.S. Air Force.

Meyer started working with laser diagnostics when he was a doctoral student in mechanical engineering at the University of Illinois at Urbana-Champaign. The work continued when he spent six years as a scientist developing and applying laser techniques for the Air Force Research Laboratory at Wright-Patterson Air Force Base in Dayton, Ohio.

He made the move to Iowa State in 2006 and is working to apply some of the military’s sophisticated laser technologies to civilian applications.

And so Meyer’s system of high-speed lasers, frequency conversion units, mirrors and cameras is being built in his Multiphase Reacting Flow Laboratory on the ground floor of Iowa State’s Black Engineering Building.

It’s work that could have impacts far beyond his lab. Meyer said his research aims to reduce reliance on fossil fuels, which currently account for 85 percent of the world’s energy use.