May 28 2008

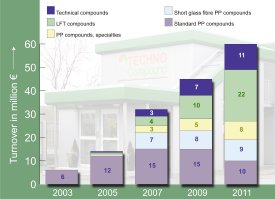

Compounding specialist TechnoCompound, Bad Sobernheim/Germany, plans to further expand its production of long fibre reinforced thermoplastics (LFTs) and engineering polymers in the course of the next few years. This was the announcement made to journalists in April by managing director Hans-Dieter Voss. Following the installation of two new compounding lines towards the end of 2007, the company now has an annual production capacity of 50,000 tonnes, of which 15,000 tonnes are reserved for special-purpose LFTs. Thus TechnoCompound has more than doubled its compounding capacity since splitting from PolymerChemie at the end of 2005.

According to a current survey carried out by Townsend Polymer Services and Information, the market demand for rod-shaped LFT pellets totalled 60,000 tonnes in Europe in 2007 and is expected to grow to 100,000 tonnes by 2011. TechnoCompound's share of the market was in the region of 6% last year and is to be increased to over 20% by 2011 – which corresponds to an annual growth rate of approx. 50%. Managing director Hans-Dieter Voss says: "Especially in the automotive industry there is still a high demand for high-tech plastics as weight-reducing substitutes for metals. And there is also a high demand in other branches of industry, too. For these customers we are developing individual and customized solutions that will also expand our portfolio of LFT compounds."

A particular feature of the LFT compounds from TechnoCompound is their very high degree of impregnation: thanks to optimized pultrusion technology, each individual glass filament is completely enveloped in the polymer matrix. This affords the glass fibres better protection during the various stages of the injection moulding process, i.e. homogenizing, plasticizing and injection. Moreover, the complete envelopment of the glass fibres makes for a high surface quality of the moulded part. The density of the surface also reduces corrosion, as no moisture can penetrate it. TechnoCompound's range meanwhhile includes emission-optimized LFT-PP compounds that are particularly suitable for use in vehicle interiors. Further long fibre reinforced PP grades and long fibre reinforced PET grades are currently under development.

The new magnetite-filled PP compounds from TechnoCompound are ideal for applications in which noise must be reduced as much as possible for improved user comfort. Possible areas of application are sewage piping in the interiors of buildings and ventilation valves, shafts and housings for microfilter systems in the automotive industry. Compared with conventional, barium sulphate-filled compounds, magnetite-filled compounds manifest a better surface quality and can therefore be used for parts that are exposed to view. By reason of its high density, magnetite (Fe3O4) possesses extremely good soundproofing properties. The compounds come in a choice of 'light' (density: 1.8 g/cm³), 'heavy' (density: 2.1 g/cm³) and 'super heavy' (density: 3.1 g/cm³) grades.