Jul 29 2009

Recent research into the properties of graphene nanoribbons provides two new reasons for using the material as interconnects in future computer chips. In widths as narrow as 16 nanometers, graphene has a current carrying capacity approximately a thousand times greater than copper-while providing improved thermal conductivity.

The current-carrying and heat-transfer measurements were reported by a team of researchers from the Georgia Institute of Technology. The same team had previously reported measurements of resistivity in graphene that suggest the material's conductance would outperform that of copper in future generations of nanometer-scale interconnects.

"Graphene nanoribbons exhibit an impressive breakdown current density that is related to the resistivity," said Raghunath Murali, a senior research engineer in Georgia Tech's Nanotechnology Research Center. "Our measurements show that these graphene nanoribbons have a current carrying capacity at least two orders of magnitude higher than copper at these size scales."

Measurements of thermal conductivity and breakdown current density in narrow graphene nanoribbons were reported June 19 in the journal Applied Physics Letters. The research was supported by the Semiconductor Research Corporation/DARPA through the Interconnect Focus Center and by the Nanoelectronics Research Initiative through the Institute for Nanoelectronics Discovery and Exploration (INDEX).

The unique properties of graphene-which is composed of thin layers of graphite-make it attractive for a wide range of potential electronic devices. Murali and his colleagues have been studying graphene as a potential replacement for copper in on-chip interconnects, the tiny wires that are used to connect transistors and other devices on integrated circuits. Use of graphene for these interconnects, they believe, would help extend the long run of performance improvements in integrated circuit technology.

"Our measurements show that graphene nanoribbons have a current carrying capacity of more than 108 AMps per square centimeter, while a handful of them exceed 109 AMps per square centimeter," Murali said. "This makes them very robust in resisting electromigration and should greatly improve chip reliability."

Electromigration is a phenomenon that causes transport of material, especially at high current density. In on-chip interconnects, this eventually leads to a break in the wire, which results in chip failure.

"We are learning a lot of new things about this material, which will lead researchers to consider other potential applications," said Murali. "In addition to the high current carrying capacity, graphene nanoribbons also have excellent thermal conductivity."

Because heat generation is a significant cause of device failure, the researchers also measured the ability of the graphene nanostructures to conduct heat away from devices. They found that graphene nanoribbons have a thermal conductivity of more than 1,000 watts per meter Kelvin for structures less than 20 nanometers wide.

"This high thermal conductivity could allow graphene interconnects to also serve as heat spreaders in future generations of integrated circuits," said Murali.

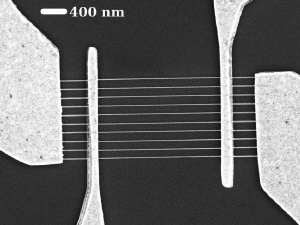

To study the properties of graphene interconnects, Murali and collaborators Yinxiao Yang, Kevin Brenner, Thomas Beck and James Meindl began with flakes of multi-layered graphene removed from a graphite block and placed onto an oxidized silicon substrate. They used electron beam lithography to construct four electrode contacts, then used lithography to fabricate devices consisting of parallel nanoribbons of widths ranging between 16 and 52 nanometers and lengths of between 0.2 and 1 micron.

The breakdown current density of the nanoribbons was then studied by slowly applying an increasing amount of current to the electrodes on either side of the parallel nanoribbons. A drop in current flow indicated the breakdown of one or more of the nanoribbons.

In their study of 21 test devices, the researchers found that the breakdown current density of graphene nanoribbons has a reciprocal relationship to the resistivity.

Because graphene can be patterned using conventional chip-making processes, manufacturers could make the transition from copper to graphene without a drastic change in chip fabrication.

"Graphene has very good electrical properties," Murali said. "The data we have developed so far looks very promising for using this material as the basis for future on-chip interconnects."