Feb 8 2010

Scientists develop new composite material that could revolutionise car design and manufacturing.

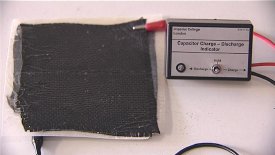

A photo of the composite material releasing electrical energy to power a small light- image courtesy of Imperial College London

A photo of the composite material releasing electrical energy to power a small light- image courtesy of Imperial College London

Parts of a car's bodywork could one day double up as its battery, according to the scientists behind a new €3.4 million project announced today.

Researchers from Imperial College London and their European partners, including Volvo Car Corporation, are developing a prototype material which can store and discharge electrical energy and which is also strong and lightweight enough to be used for car parts.

Ultimately, they expect that this material could be used in hybrid petrol/electric vehicles to make them lighter, more compact and more energy efficient, enabling drivers to travel for longer distances before needing to recharge their cars.

In addition, the researchers believe the material, which has been patented by Imperial, could potentially be used for the casings of many everyday objects such as mobile phones and computers, so that they would not need a separate battery. This would make such devices smaller, more lightweight and more portable.

The project co-ordinator, Dr Emile Greenhalgh, from the Department of Aeronautics at Imperial College London, says:

"We are really excited about the potential of this new technology. We think the car of the future could be drawing power from its roof, its bonnet or even the door, thanks to our new composite material. Even the Sat Nav could be powered by its own casing. The future applications for this material don't stop there - you might have a mobile phone that is as thin as a credit card because it no longer needs a bulky battery, or a laptop that can draw energy from its casing so it can run for a longer time without recharging. We're at the first stage of this project and there is a long way to go, but we think our composite material shows real promise."

In the new project, the scientists are planning to develop the composite material so that it can be used to replace the metal flooring in the car boot, called the wheel well, which holds the spare wheel. Volvo is investigating the possibility of fitting this wheel well component into prototype cars for testing purposes.

The team says replacing a metal wheel well with a composite one could enable Volvo to reduce the number of batteries needed to power the electric motor. They believe this could lead to a 15 per cent reduction in the car's overall weight, which should significantly improve the range of future hybrid cars.

Current hybrid cars consist of an internal combustion engine, which is used when the driver accelerates the car, and an electric motor powered by batteries, which turns on when the car is cruising. The cars need a large number of batteries to power the electric motor, which makes the vehicle heavier, meaning that the car uses up more energy and the batteries need regular recharging at short intervals.

The researchers say that the composite material that they are developing, which is made of carbon fibres and a polymer resin, will store and discharge large amounts of energy much more quickly than conventional batteries. In addition, the material does not use chemical processes, making it quicker to recharge than conventional batteries. Furthermore, this recharging process causes little degradation in the composite material, because it does not involve a chemical reaction, whereas conventional batteries degrade over time.

The material could be charged by plugging a hybrid car into household power supply. The researchers are also exploring other alternatives for charging it such as recycling energy created when a car brakes.

For the first stage of the project, the scientists are planning to further develop their composite material so that it can store more energy. The team will improve the material's mechanical properties by growing carbon nanotubes on the surface of the carbon fibres, which should also increase the surface area of the material, which would improve its capacity to store more energy.

They are also planning to investigate the most effective method for manufacturing the composite material at an industrial level.

The 3-year European Union funded project includes researchers from the Departments of Chemistry, Aeronautics and Chemical Engineering and Chemical Technology at Imperial College London. European academic and industrial partners include Swerea SICOMP, INASCO Hella, Chalmers, Advanced Composites Group, Nanocyl, Volvo Car Corporation, Bundesanstalt Fur Materialforschung undprufung, ETC Battery and Fuel Cells Sweden.