May 6 2010

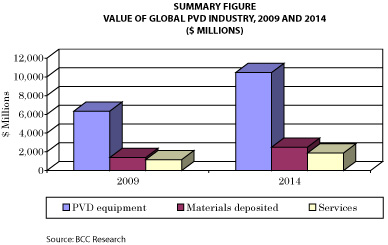

According to a new technical market research report, PHYSICAL VAPOR DEPOSITION (PVD): GLOBAL MARKETS (MFG015D) from BCC Research, the value of the global PVD industry was nearly $9 billion in 2009, but is expected to increase to more than $14.8 billion in 2014, for a 5-year compound annual growth rate (CAGR) of 10.7%.

The largest segment of the market, PVD equipment, is projected to increase at a CAGR of 10.5% to nearly $10.5 billion in 2014, after being valued at nearly $6.4 billion in 2009.

Materials deposited, which make up the second-largest segment of the market, are estimated at $1.4 billion in 2009, and are expected to increase at a 5-year CAGR of 12.2% to reach more than $2.5 billion in 2014.

The services segment is projected to have a CAGR of 9.8%, with values of nearly $1.2 billion in 2009 and nearly $1.9 billion in 2014.

The PVD industry has expanded over the past several decades. More sophisticated manufacturing and fabrication techniques and smaller-sized products have broadened the demand for vapor-deposited materials. New and existing products require materials that can be delivered by vacuum deposition of films on a growing variety of substrates.

This study encompasses PVD technologies and materials in terms of application, properties and processes. BCC Research analyzes the major types of PVD systems and materials used to manufacture products in eight key industries. Applications are discussed, as are properties imparted by PVD. Trends in demand also are reviewed and their impacts on PVD are assessed.

Market drivers within each industry are identified. Materials deposited by PVD are analyzed according to basic functions (e.g., wear resistance, abrasion and corrosion resistance, conductivity and barrier protection). The value of PVD equipment shipments is projected within each industry by type of system. Material shipment values are projected, along with PVD service revenues. Technological issues and trends are reviewed, and other influential factors, such as economic conditions and standards, are discussed.

This study will be of interest to those in the microelectronics business, manufacturers of cutting tools, specialty packagers, makers of storage equipment and media, companies in the solar energy business, manufacturers of automotive and aerospace parts, medical device makers, and those in the optics industry. It will also be of interest to companies engaged in the manufacture of deposition equipment and materials, and to surface coaters.