May 17 2010

The Siemens Industry Solutions Division (IS) is one of the world's leading solution and service providers of plants and systems for industry and infrastructure, focusing on innovations that save resources, water and energy in metals and mining applications.

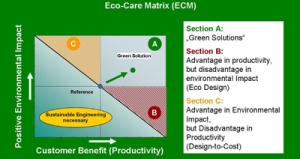

Jens Wegmann, CEO of the Siemens IS Division, said at the 4th Media Summit Metals & Mining Technologies in Essen, "Rising energy prices, legal requirements and a deeper awareness of ecological responsibility are leading to greater environmental protection and higher energy efficiency. Sustainability and cost effectiveness are not a contradiction. The Eco-Care Matrix, devised jointly by IS and universities, can assess the environmental compatibility and cost effectiveness of everything from single products to complete industrial plants. New products can also be specifically geared toward sustainability, cost efficiency and environmental protection."

The Eco-Care Matrix

The Eco-Care Matrix

He added, "The development of green products and solutions has become increasingly important as a result of climate change and the increasing scarcity of resources. The Eco-Care Matrix helps us to develop innovations on the basis of comparable metrics. This means that individual products, systems and complete plants can be assessed and developed to ensure that they not only meet cost and energy efficiency targets, but also satisfy important ecological requirements." Capital and operating costs are shown on one side, and the environmental impact on the other. This enables us to create green solutions that are both kind on the environment and profitable. Wegmann emphasized, "As a result, we are offering sustainable, cost-effective benefits to our customers and helping them to remain competitive throughout the world."

Among the examples Wegmann cited was the Corex/Finex technology from Siemens VAI, which the Eco-Care Matrix has identified as a green solution. Unlike the conventional blast furnace process, which requires coke and sintered ore to produce pig iron from iron ore, the Corex/Finex method requires neither coking nor sintering plants. This not only reduces carbon dioxide emissions and the consumption of resources; investment and production costs are also lower than is the case with a conventional blast furnace.

The IS Division intends to significantly increase the proportion of environmental solutions in its total sales from the current level of 33 percent by 2015.