Aug 27 2010

European researchers have combined computer modelling of quantum mechanics and precision fabrication processes to create novel transparent conductive oxides made to order for a wide range of scientific and consumer applications.

Imagine specifying exactly how you want a new material to behave, handing those specs to an engineer, and getting back a brand-new material with exactly the qualities you need.

That’s what the EU-funded project NATCO (for Novel Advanced Transparent Conductive Oxides) set out to do. They designed and developed novel transparent conductive oxides (TCOs) to exacting specifications by applying quantum mechanics to predict a material’s optical and electronic properties, fabricating it, and checking their results experimentally.

The results? Completely new TCOs with a wide range of potential applications in sensors, solar cells, smart windows, and dozens of other scientific, commercial and consumer products.

TCOs – materials that combine transparency and conductivity, qualities that are not usually found together – have multiple applications.

TCOs – materials that combine transparency and conductivity, qualities that are not usually found together – have multiple applications.

“In the field of optoelectronics, there’s a great need to find better and less costly materials,” says Guy Garry, coordinator of the NATCO project. “The route we took was first to make calculations to find the best way to get the properties that we needed. When we fabricated these materials, we found that their properties were the same as we had calculated.”

This rational design process – using first principles to calculate the conductivity and transparency of novel materials before fabricating them – allowed the researchers to develop new TCOs with enhanced performance rapidly and efficiently.

“We were able to make these calculations very quickly, which allowed us to enhance existing properties and find new properties,” says Dr Garry.

Brand new optoelectronic material

TCOs – materials that combine transparency and conductivity, qualities that are not usually found together – have multiple applications. As sensors, photovoltaics, light emitting devices and electronically controllable films, they are found in scientific instruments, DVDs, digital cameras, mobile phones, computer displays and hundreds of other products.

Until recently, most TCOs relied on a material called ITO, an oxide of indium which is doped – slightly modified – by the addition of a small quantity of tin. ITOs have proved useful, but, Dr Garry says, suffer from two drawbacks. Their transparency is not very good, especially in the near-infrared range, and indium is in short supply and very expensive.

The NATCO team decided to explore a completely different material, strontium cuprate doped with varying amounts of barium. Copper, barium and strontium are far more abundant and much less expensive than indium.

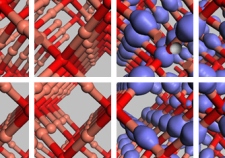

Extensive calculations applying quantum mechanics predicted that, by doping strontium cuprate with a few percent by weight of barium, the researchers could create precisely the materials they wanted, combining good electrical conductivity and optical transparency.

Fabricating the new materials was a challenge. At first the materials were fabricated in the form of bulk ceramics and then, for actual applications, thin layers were deposited on suitable substrates.

In the end, the researchers settled on two deposition techniques – pulsed laser deposition (PLD) and metal organic chemical deposition (MOCVD).

In PLD, a burst of laser light vaporises the material to be deposited, creating a thin film on a glass or silicon surface. It allows precise control, but can’t be used on large surfaces.

MOCVD uses organic chemistry to create gasses that deposit the desired material onto a surface. It is a more complicated procedure, but has the advantage of being able to be scaled up to coat large surfaces.

Once they had fabricated the materials, the researchers could test how well their electrical and optical properties matched the predicted values. “This was the first time that this kind of work was done on TCOs,” says Dr Garry.

Multiple applications in the works

Today, one of the most promising applications of NATCO’s new TCOs is in the area of exquisitely sensitive biosensors. These devices, with the tongue-twisting title of Elecro-Chemical Optical Waveguide Light-mode Spectroscopy Sensors, are fabricated by the Hungarian consortium partner MicroVacuum. They work by measuring how light is bent as it passes through a very thin optical wave guiding layer.

When target molecules bind to the surface of the detector, they change the TCO´s refractive index, which in turn changes how light passes through the waveguide. Applying a varying electric field through the layer provides further information about the molecules.

“We got very good results on these devices using our strontium cuprate materials,” says Dr Garry. He foresees a wide range of applications for these sensors, especially in the area of proteomics.

The project’s commercial and academic partners are pursuing other applications for NATCO’s designer TCOs, including more efficient solar cells, smart windows, novel light sources, and materials to modulate laser light.

For Dr Garry, the results of the project’s first-principles modelling and precision fabrication approach are so encouraging that he plans to apply them to more challenging problems.

“We’d like to use this route to study more complicated materials,” he says. “For example, to look at ferro-electricity to see why some materials with the same structure are ferro-electric while others are not.”

The NATCO project received funding from the FET-Open strand of the EU’s Sixth Framework Programme for research.