Jan 25 2011

As one of the industry leaders for tailored optical coatings, Optics Balzers is a key provider of cover glasses for image sensors and microdisplays.

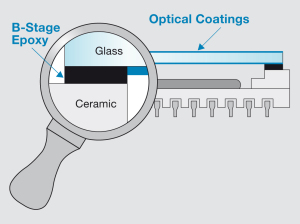

Optics Balzers has recently made continuous efforts to expand its optical packaging portfolio, with a focus on different sealing options. The existing B-stage epoxy sealing solution from Optics Balzers features a particle-free, “low defect” application of the adhesive onto cover glasses, which traditionally exhibit an antireflection coating of variable spectral width. After pre-curing of the adhesive frame, the cover glasses are packaged and shipped to the customer in a ready-to-cure state.

Schematic of sealed B-stage Epoxy glass lid

Schematic of sealed B-stage Epoxy glass lid

On the basis of the well-established B-stage epoxy, Optics Balzers now offers an extended range of cover glass sealing options. Continuous collaborations with adhesive manufacturers and custommized adaptations to the epoxy application techniques have resulted in a substantial decrease of the minimum epoxy feature size. Currently, Optics Balzers is able to provide cover glasses with B-staged epoxy lines as narrow as 500 ìm and with a minimum adhesive thickness of 10 ìm.

The simultaneously introduced wafer-level production facilitates the efficient fabrication of cover lids with dimensions in the millimeter range, commonly found in MEMS/MOEMS devices. The in-house dicing capabilities complete the efforts at Optics Balzers to provide its customers with tailored cover glass solutions which are readily accessible for assembly.

In the face of small adaptations, the main characteristics of the B-stage epoxy, including moderate heat cure cycles (30 – 60 min, 90 – 120°C), low pressure requirements during cover glass assembly (0.5 – 1.0 N/cm2) as well as exceptional adhesion to a variety of optical coatings, could be retained. Additionally, the residual elasticity of the epoxy in the cured state allows for the bonding of materials with dissimilar coefficients of thermal expansion (CTE) and the black color of the B-stage epoxy serves as aperture with a reflectivity below 3% in the visible range.

Ongoing R&D projects at Optics Balzers aim at the extension of the available B-stage epoxy functionnalities according to customer needs, for example towards electrical and thermal conductivity, or biocompatibility. For applications with more stringent hermetic requirements, Optics Balzers offers cover glasses with patterned Gelot™ solderable coatings. In the near future, customers will be provided with customized “low defect” subassemblies, i.e. cover glasses hermetically soldered onto metal frames such as Kovar.