Feb 4 2011

In November 2010, Sumitomo Metal Industries Ltd. gave Siemens VAI Metals Technologies the final acceptance certificate for the Mulpic® (Multi-Purpose-interrupted-Cooling) system installed in the plate rolling mill at their Kashima Works.

Sumitomo is the first Japanese steelmaker to choose Mulpic® for the production of high quality plates for shipbuilding and pipe production. The cooling system was part of an extensive modernization of the heavy-plate line in Kashima, and will improve the output and quality of the products even further.

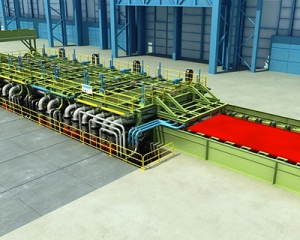

Computer generated animation of the Mulpic® cooling system

Computer generated animation of the Mulpic® cooling system

The installation of the intensive cooling system in Sumitomo´s Kashima Works was completed following a planned 25-day plant shutdown in the summer of 2010, which included the removal of an existing cooling system. The modular design philosophy used in the Mulpic® reduced installation time and Final Acceptance was achieved with all guarantees passed. Tatsuo Tanaka of Sumitomo Metal Industries commented: “we were pleased to sign off Final Acceptance on schedule. Through effective collaboration between all parties; Siemens VAI, our engineer and constructors, cold commissioning was completed in record time”.

The Siemens solution includes features such as edge masking, head and tail masking and water crown control, as well as the automation system for precise and uniform control of the cooling process in the production of modern materials. Mulpic® has a wide control range, which provides high cooling rates, including direct quenching of the plates, to control the microstructure and therefore the mechanical properties in the final plate. In addition to equipment supply, Siemens VAI will provide training and process consultancy services.