An innovative line of patterning solutions is offered by Optics Balzers, supplier of optical coatings and components.

Photolithography capabilities from Optics Balzers allow the production of high-precision patterned coatings and gratings in the submicron range.

Photolithography capabilities from Optics Balzers allow the production of high-precision patterned coatings and gratings in the submicron range.

The company provides patterning solutions to produce optical components based on customer specifications. The patterning solutions include laser ablation, masked coatings and photolithography. Many patterning techniques are used with Optics Balzers’ sputter technology for efficient applications.

Laser ablation is used to pattern optical filter coatings. This method offers excellent flexibility for production of customized patterns and shapes. It also reduces processing times. Laser ablation allows manufacturing of patterned filters to a minimum size of 100 µ.

Optics Balzers’ masked coating technology limits the size and shape of the patterns. The minimum pattern size is about 200 µ. However, the major benefit of the technique is that application can be done with any coating material or process.

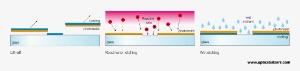

Photolithography techniques include lift-off, reactive ion etching and wet etching. These techniques enable the production of accurate and thin patterned coatings and gratings. The size of the coating patterns is smaller than 10 µ. Photolithography is mainly used to manufacture lids for CCD and CMOS image sensors and MEMS components.