Sumitomo Electric Industries announced that it has established a production line at its facility in Shimaya, Konohana-ku, Osaka to speed up the development of a new porous aluminum called Aluminum-Celmet.

Aluminum-Celmet

Aluminum-Celmet

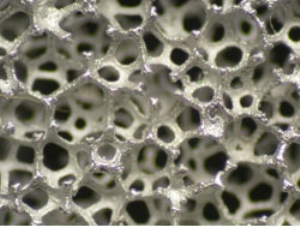

Celmet is a porous metal, which is developed from nickel chrome alloy or nickel. The manufacturing process of Celmet includes electro conductive coating, nickel plating and removal of plastic foam using heat treatment.

The porous metal has a 3-D mesh-like structure and can be easily processed into different shapes using stamping and cutting processes. The material has higher porosity than other metals such as foam metal and nonwoven metal fabric. All these attributes provide excellent filling, preserving and current-collecting performance. Hence, Celmet is currently used as a positive electrode current collector in nickel-hydrogen batteries.

Sumitomo Electric Industries has successfully developed the porous aluminum by employing the same processes used to produce nickel Celmet.

The Aluminum-Celmet is lightweight, resistant to corrosion and has higher electrical conductivity. These qualities make the porous aluminum ideal for applications in lithium-ion secondary batteries and other batteries that operate at high voltages. The porous aluminum can also be utilized for current collectors in capacitors.