CERATECH has revealed the test results that proved its KEMROK cement can bear acid attack. The innovative cement significantly reduces product downtime and maintenance expenditures. Its superior corrosion resistance increases product lifetime, which in turn yields high return on investment.

KEMROK cement demonstrates better durability to Portland cement in acid resistance tests

KEMROK cement demonstrates better durability to Portland cement in acid resistance tests

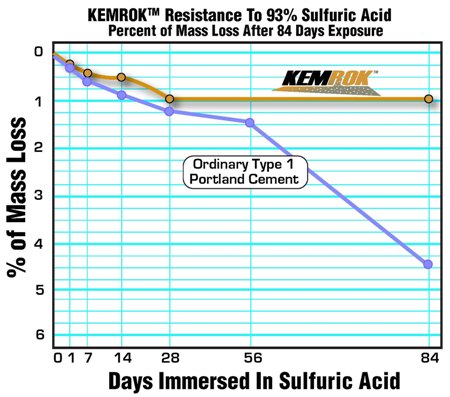

In tests conducted as per the guidelines of ASTM C-267, technicians immersed samples of concrete, one made with KEMROK cement and another one with Portland cement, in different acid solutions, including hydrochloric, acetic, phosphoric and sulfuric acid.

After exposure to 93% sulfuric acid for 84 days, the concrete made with KEMROK cement had lost just above 1% of its mass and 5% of its compressive strength, while the loss on Portland cement-based concrete’s mass was more than 4% and strength was 18%. Moreover, the Portland cement concrete had constantly deteriorated, while deterioration to KEMROK cement concrete almost ended after a month.

As concrete is continually in contact with sulfuric acid in their processing facilities, the test on sulfuric acid durability is critical for petrochemical manufacturers. KEMROK cement concrete had demonstrated superior durability than the Portland cement concrete in exposure to other acids.

As all cement products of CERATECH, including KEMROK, are produced from 95% recycled materials and 5% renewable materials in a nearly carbon-zero process, they are ideal for companies involved in green building practices. The Executive Vice President at CERATECH, Mark Wasilko stated that the company offers cement products with better sustainability, durability and they are readily available in the market.