A research team led by Todd Emrick from the University of Massachusetts Amherst has developed an experimental process to perform nano-scale repairs on damaged surfaces based on a theoretical prediction of Anna Balazs from the University of Pittsburgh.

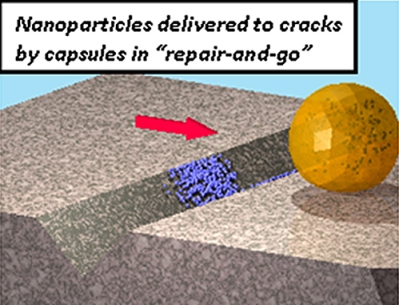

A recent materials repair discovery validates prior theory and may lead to significant conservation of material in diagnosing and repairing structural damage. The cartoon illustrates how nanoparticle-containing capsules roll or glide over damaged substrates, selectively depositing their nanoparticle contents into fractures. (illustration courtesy of Todd Emrick, UMass Amherst)

A recent materials repair discovery validates prior theory and may lead to significant conservation of material in diagnosing and repairing structural damage. The cartoon illustrates how nanoparticle-containing capsules roll or glide over damaged substrates, selectively depositing their nanoparticle contents into fractures. (illustration courtesy of Todd Emrick, UMass Amherst)

This experimental technique is capable of repairing a damaged surface using microscopic amounts of material and eliminates the necessary to coat whole surfaces when only a small portion is damaged. Emrick added that the demand for quick, efficient repair and coating mechanisms is ever-increasing in all products ranging from biological implant devices to microelectronic materials to airplane wings.

Emrick further said that when compared to undamaged surfaces, damaged surfaces demonstrate different characteristics in terms of chemical functionality, roughness, wetting characteristics and topography at the nano-scale. Utilizing computer simulation, Anna Balazs predicted that microcapsules containing nanoparticles can be used for investigating a surface and delivering the nanoparticles into the damaged part of the surface, thus enabling an efficient spot-repair called ‘repair-and-go’, he added.

To experimentally prove the concept, the research team used the expertise of three polymer materials labs at the University of Massachusetts Amherst. The team used a polymer surfactant for stabilizing emulsion droplets or capsules in water in order to efficiently encapsulating nanoparticles. Emrick stated that the team discovered the selective release of the nanoparticle components by the microcapsules into the damaged surfaces. The localization of the nanoparticles in the damaged surface can be traced easily, as they are fluorescent.

Emrick emphasized that besides depositing sensor material in cracked surfaces, the novel encapsulation process is also capable of identifying the cracked regions. The novel work also eliminates the use of organic solvents, as it enables the delivery of hydrophobic materials in aqueous systems, thus making it an eco-friendly process, he added. The team plans to extend its research to recover coated objects’ mechanical properties by altering the nanoparticles’ composition, he said.